Method for producing industrial-grade ammonium dihydrogen phosphate and co-producing water-soluble fertilizer

A technology of grade ammonium dihydrogen phosphate and production method, which is applied in the directions of ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, phosphate fertilizer, etc., can solve the problems of chaotic production process of water-soluble fertilizer, simple miniaturization, useless industrial monoammonium phosphate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

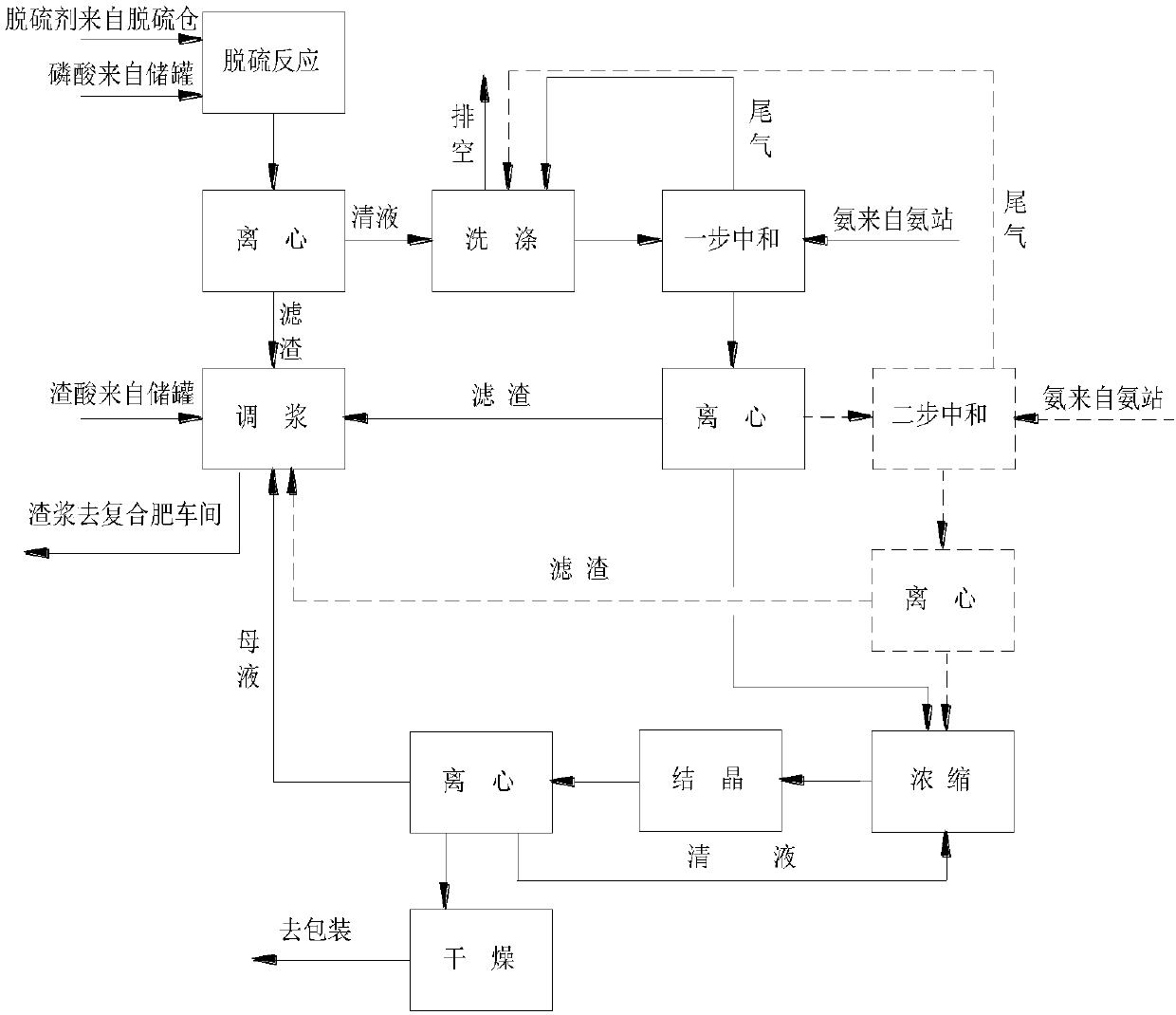

[0049] Embodiment 1: Industrial grade ammonium dihydrogen phosphate co-production water-soluble fertilizer production process:

[0050] 1. Production process of ammonium dihydrogen phosphate

[0051] 1.1. Mix wet-process phosphoric acid and phosphate rock powder as a desulfurizing agent evenly, and then enter the desulfurization reactor for desulfurization reaction. The desulfurization reaction temperature is 70°C, and the reaction time is 30 minutes. After the reaction, the desulfurized phosphoric acid slurry is sent to the push material Centrifugal separation in a screw centrifuge, the filtrate is sent to a neutralizer for neutralization reaction with liquid ammonia, the temperature of the first neutralization reaction is 70°C, and the pH value of the neutralization reaction slurry is 4;

[0052]1.2. After the neutralization reaction in step 1.1 is completed, the slurry is sent to a pusher screw centrifuge for centrifugation, and the centrifuged filtrate of the primary neutr...

Embodiment 2

[0058] Embodiment 2: Industrial grade ammonium dihydrogen phosphate co-production water-soluble fertilizer production process:

[0059] 1. Production process of ammonium dihydrogen phosphate

[0060] 1.1. Mix wet-process phosphoric acid and phosphate rock powder as a desulfurizing agent evenly, and then enter the desulfurization reactor for desulfurization reaction. The desulfurization reaction temperature is 85°C, and the reaction time is 40 minutes. After the reaction, the desulfurized phosphoric acid slurry is sent to the push material Centrifugal separation in a screw centrifuge, and the filtrate is sent to a primary neutralizer for neutralization reaction with liquid ammonia. The temperature of the primary neutralization reaction is 80°C, and the pH value of the neutralization reaction slurry is 4.3;

[0061] 1.2. After the neutralization reaction in step 1.1 is completed, the slurry is sent to a pusher screw centrifuge for centrifugation, and the centrifugal filtrate of ...

Embodiment 3

[0067] Embodiment 3: Industrial grade ammonium dihydrogen phosphate co-production water-soluble fertilizer production process:

[0068] 1. Production process of ammonium dihydrogen phosphate

[0069] 1.1. Mix wet-process phosphoric acid and phosphate rock powder as a desulfurizing agent evenly, and then enter the desulfurization reactor for desulfurization reaction. The desulfurization reaction temperature is 90°C, and the reaction time is 50 minutes. After the reaction, the desulfurized phosphoric acid slurry is sent to the push material Centrifugal separation in a screw centrifuge, the filtrate is sent to a neutralizer for neutralization reaction with liquid ammonia, the temperature of the first neutralization reaction is 90°C, and the pH value of the neutralization reaction slurry is 4.6;

[0070] 1.2. After the neutralization reaction in step 1.1 is completed, the slurry is sent to a pusher screw centrifuge for centrifugation, and the centrifugal filtrate of the primary ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com