Chromium-free tanning production process of low-formaldehyde beach woolskin

A production process and low-formaldehyde technology, applied in small raw hide/big raw hide/leather/fur treatment, small raw hide/big raw hide/leather skin/fur chemical treatment, pre-tanning chemical treatment, etc., can solve the problem of difficulty in maintaining naturalness, The formaldehyde content exceeds the standard, which will cause pollution and other problems, so as to achieve the effect of plump hand feeling, pure white coat color and reduced treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

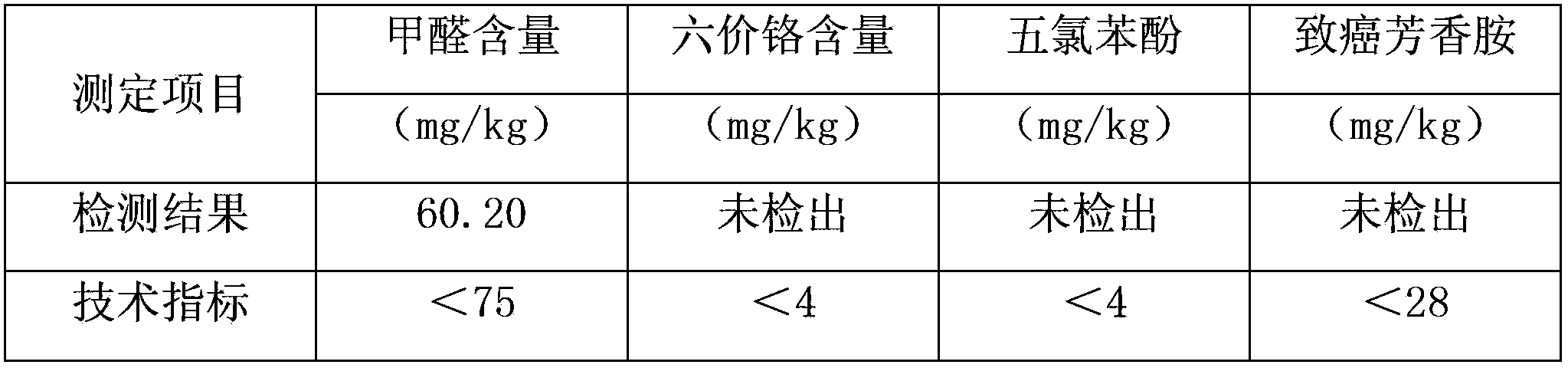

Embodiment 1

[0033] The chrome-free tanning process of chrome-free tanning agent TWT tanning low-formaldehyde beach sheepskin in the present embodiment, comprises the following steps successively:

[0034] Soaking in water: Soak the beach sheepskin in the soaking liquid at a temperature of 30-35°C for 12-24 hours. The composition of the soaking liquid is: fungicide Diamoll WEF Powder 0.5-1.5g / L, table salt 10-25g / L , degreasing agent TPL 0.5-2.5g / L, soaking enzyme Feliderm SE 3Powder 0.1-1.5g / L, and the rest is water; the amount of soaking liquid should be 20-30 in the mass ratio of water and fur in the soaking liquid.

[0035] to the meat.

[0036] Degreasing: In the degreasing solution, paddle for 30-120 minutes at a temperature of 35-40°C. , the composition of the degreasing liquid is: soda ash 0.5-1.5g / L, compound enzyme DESOBATE LG 0.1-1.5g / L, penetrant JFC0.5-1.5g / L, degreasing agent PX 2-5g / L, and the rest are Water; the amount of degreasing liquid is preferably 20-40 with the mas...

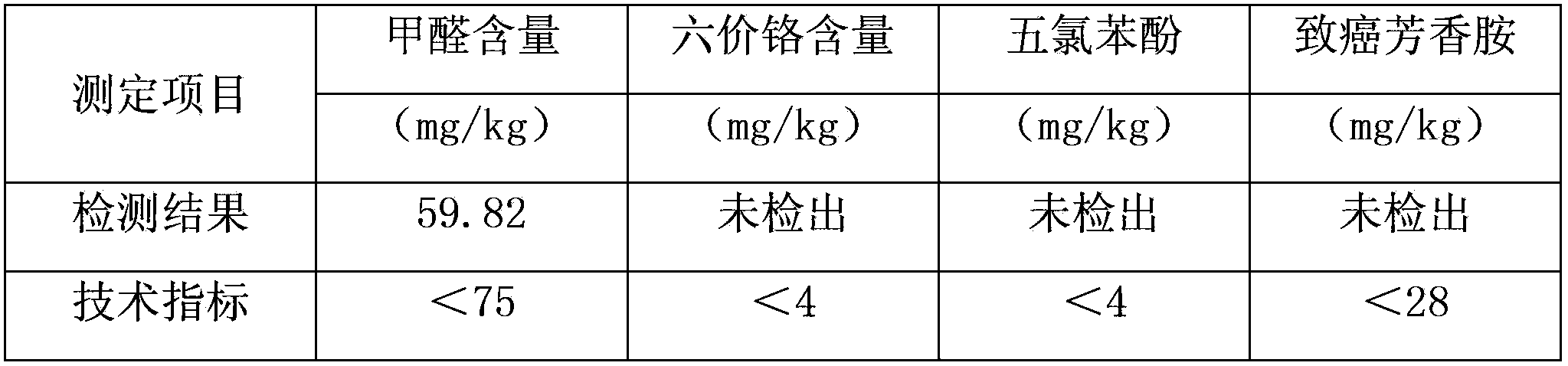

Embodiment 2

[0053] The chrome-free tanning process of chrome-free tanning agent TWT tanning low-formaldehyde beach sheepskin in the present embodiment, comprises the following steps successively:

[0054] Tanning: after the above steps, put the Tan sheepskin in the groove for tanning, use 20L water for each Tan sheepskin, add chelating dispersant DT-A101 (Demei Chemical) 0.4g / L, chrome-free tanning agent TWT (Demei Chemical) 8g / L, whitening agent W-HC (Fanbo Technology) 0.4g / L, degreasing agent DESOAGEN N309 (Desaier Chemical) 0.6g / L, the temperature is 36°C, and the pH is adjusted to 4.7 After padding for 150 minutes, let it stand overnight. The next day, use a magenta indicator to check the color of the incision. If it is purple and uniform in color, it proves that the penetration is complete.

[0055] Alkali extraction after tanning: add baking soda to the tanning solution after standing to extract alkali. The concentration of baking soda is 1.9g / L, take out 10 times of the tanning so...

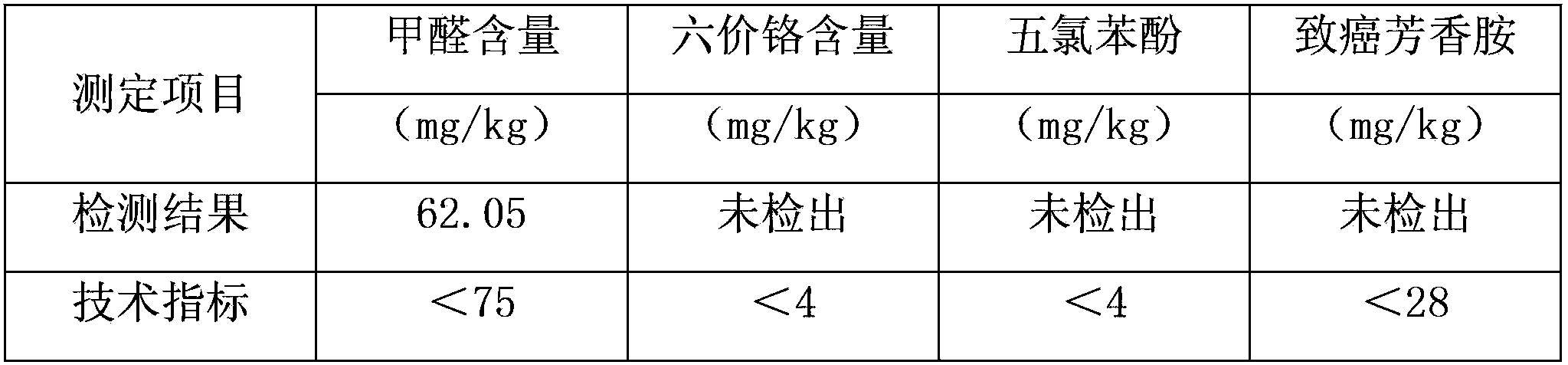

Embodiment 3

[0063] The chrome-free tanning process of chrome-free tanning agent TWT tanning low-formaldehyde beach sheepskin in the present embodiment, comprises the following steps successively:

[0064] Tanning: put the Tan sheepskin in the groove after the above steps for tanning, use 40L water for each Tan sheepskin, add 1.2g / L of chelating dispersant Lushuntong RED (BASF), and chrome-free tanning agent TWT (Demei Chemical) 14g / L, whitening agent WZS (Fanbo Technology) 0.8g / L, Weiss fur degreasing agent JA-50 (Fanbo Technology) 1.2g / L, the temperature is 42°C, and the pH is adjusted to 5.0 After padding for 120 minutes, let it stand overnight. The next day, use magenta indicator to check the color of the incision. If it is purple and uniform in color, it proves that the penetration is complete.

[0065] Alkali extraction after tanning: add baking soda to the tanning solution after standing to extract alkali. The concentration of baking soda is 1.4g / L, take out 10 times of the tanning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com