Method for preparing high-purity polycrystalline silicon under action of electric field and fused salt

A polycrystalline silicon and molten salt technology, applied in the growth of polycrystalline materials, chemical instruments and methods, single crystal growth, etc., can solve the problems of easy reaction with molten silicon liquid, difficult to avoid electrodes, etc., to enhance the impurity removal effect, The effect of reducing the cutting length and reducing the impurity concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

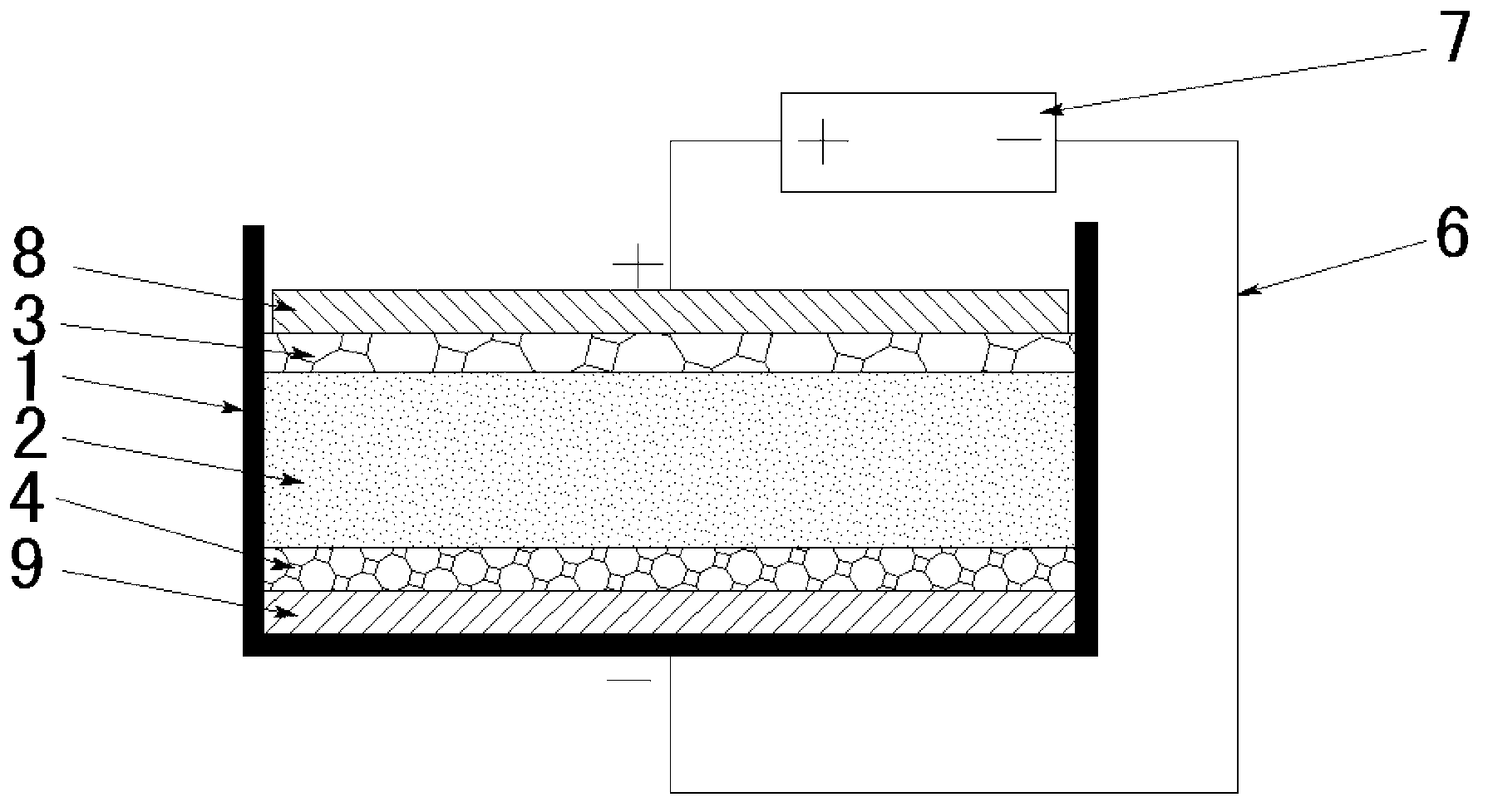

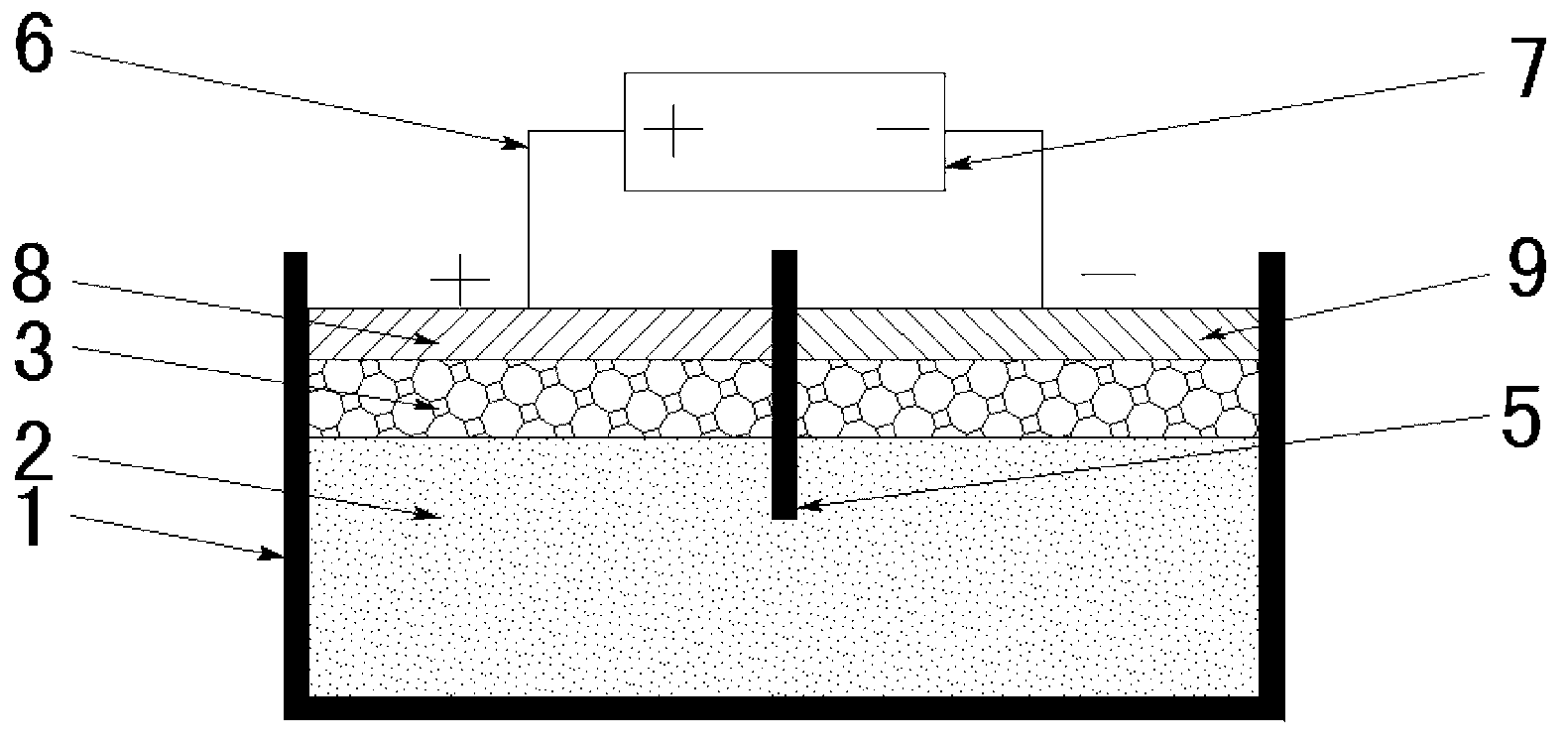

[0033] Example 1 as figure 1 In the method of adding molten salt shown, a flat cathode electrode 9 is set at the inner bottom of the crucible 1, and then 2.4Kg of high-density molten salt 4 is added to the crucible. The high-density molten salt uses CaO-SiO with a mass ratio of 3:3:4. 2 -CaF 2 , and then add 10Kg silicon material 2 above the molten salt. Above the silicon material 2, a flat anode electrode 8 is set at a distance from the surface of the silicon material, and the position of the flat anode electrode can be adjusted by a lifting device (in figure 1 not pictured). The flat anode electrode 8 is connected to the positive pole of the DC power supply 7 with the wire 6, and the flat cathode electrode 9 is connected to the negative pole. The flat anode electrode 8 and the flat cathode electrode 9 are made of high-purity graphite, and the wire 6 is made of high-purity molybdenum wire. When arranging the electrodes, pay attention to make the direction of the electric ...

Embodiment 2

[0037] Embodiment 2: with figure 1 In the way of adding molten salt shown, the high-density molten salt 4 uses SiO with a mass ratio of 17:2:1 2 -Al 2 o 3 -K 2 O, the addition amount is 2.4Kg, and the small-density molten salt 3 adopts Si with a mass ratio of 1:6:4 3 N 4 -KCl-MgCl 2 , the add-on is 2.5Kg, the silicon material add-on is 10Kg, all the other steps are with embodiment 1.

Embodiment 3

[0038] Embodiment 3: with figure 1 The method of adding molten salt is shown as an example. The high-density molten salt 4 uses BaCO with a mass ratio of 10:3:4. 3 -SiO 2 -MgF 2 , the addition amount is 2.6Kg, and the small-density molten salt 3 adopts SiO with a mass ratio of 3:4:3 2 -NaHCO 3 -KCl. Add-on amount is 2.4Kg, silicon material add-on amount is 10Kg, all the other steps are the same as embodiment 1. Examples 2 and 3 also obtained high-purity polysilicon ingots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com