Split-flow automatic control system of coal bed methane horizontal branch well and process thereof

An automatic control system and horizontal branch well technology, which is applied to the automatic control system of drilling, drilling equipment, flushing boreholes, etc., can solve the problems of large downhole pressure fluctuations, erosion of the well wall, and low rock-carrying efficiency, and eliminate Pressure fluctuations, reducing pressure fluctuations, and ensuring the effect of rock-carrying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing:

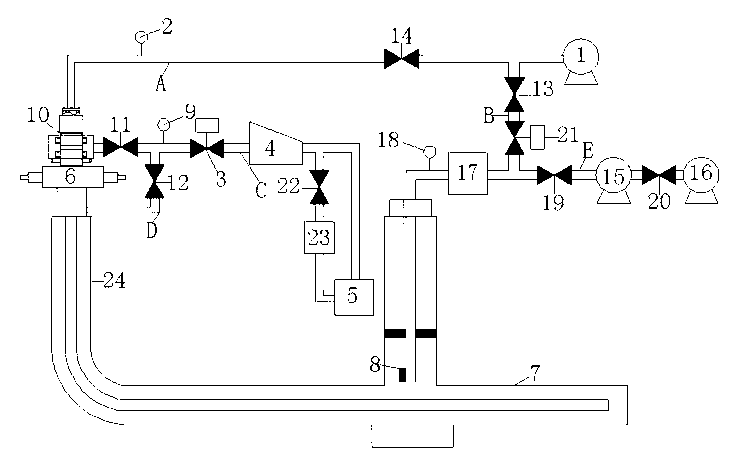

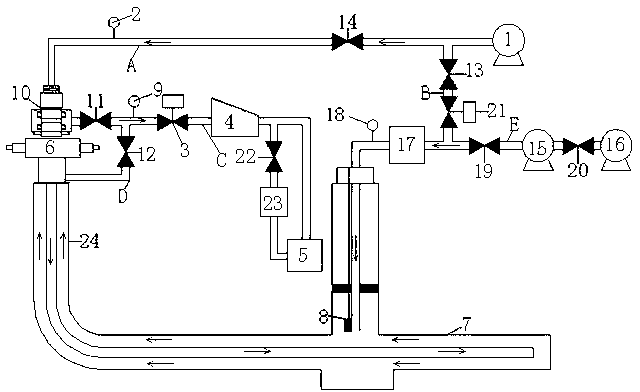

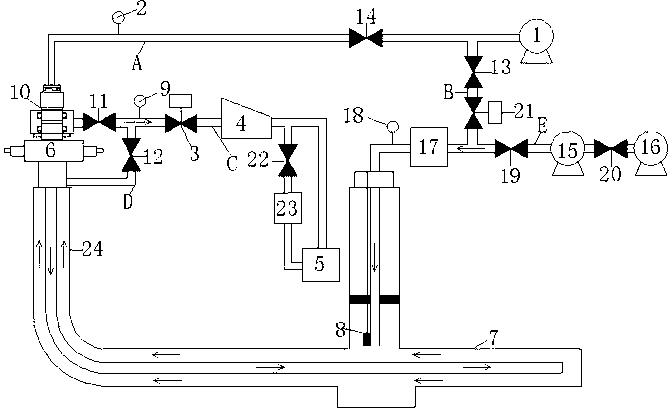

[0040] Such as figure 1 As shown in the automatic control system for diversion of coalbed methane horizontal branch wells, the coalbed methane well including the horizontal branch well 7 also includes a vertical well 24, and the upper part of the vertical well 24 is provided with a rotary control head 10 and a fully sealed ram blowout preventer 6. The coalbed methane well A mud pump 1, a mud pool 5 and an air compressor 16 are also connected, and the automatic control system for diversion of coalbed methane horizontal branch wells includes a surface manifold structure and an automatic control system.

[0041] The ground manifold structure includes the first mud input pipeline A, the second mud input pipeline B, the mud return pipeline C, the auxiliary mud return pipeline D and the gas injection pipeline E, and the first mud input pipeline A is from the mud pump 1 Connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com