Refining method of argon gas and refining device

A refining method and refining device technology, which are applied in separation methods, chemical instruments and methods, inert gas compounds, etc., can solve the problems of reduced argon recovery rate, pressure rise, increased argon gas obstruction, etc., and improved argon gas recovery rate. , The effect of eliminating pressure fluctuation and improving the effect of decompression and regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

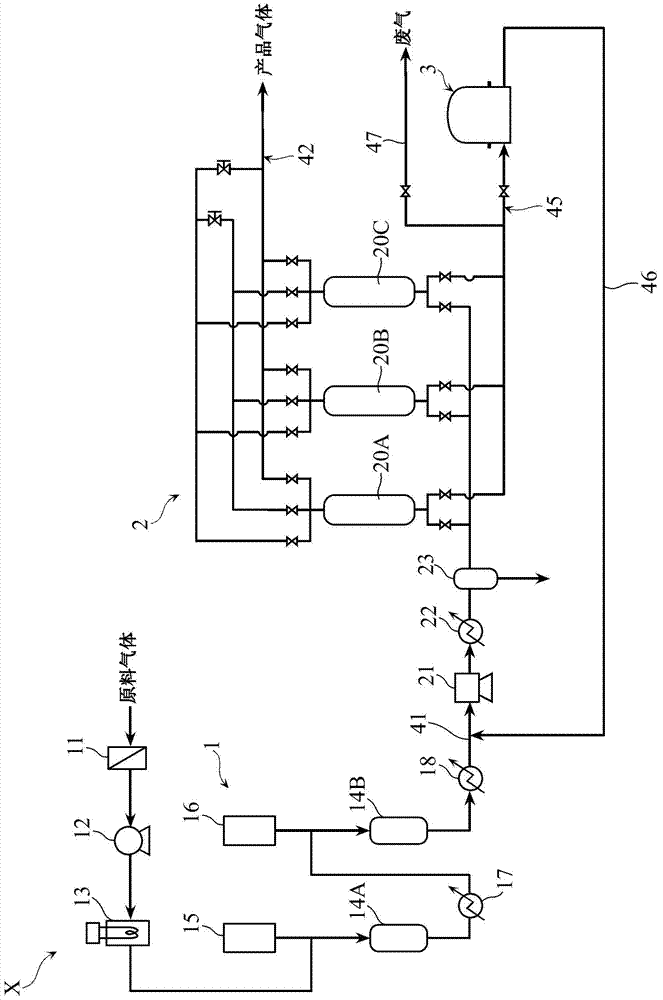

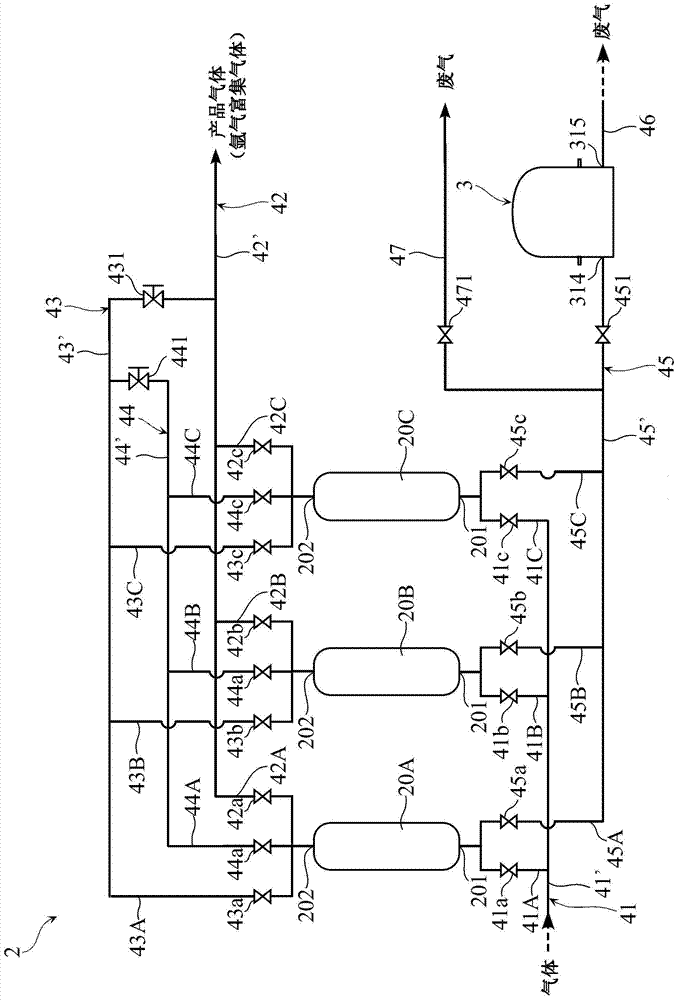

[0164] By using the figure 1 , figure 2 The argon refining device X of the schematic structure shown, and repeat in adsorption tower 20A, 20B, 20C by Figure 4 , Figure 5 The shown adsorption process, downstream decompression process, equal pressure (decompression) process, countercurrent decompression process, cleaning (first cleaning) process, cleaning (second cleaning) process, equal pressure (boosting) process and boost One cycle (steps 1 to 12) consisting of pressing process, concentrates and purifies argon from the specified mixed gas.

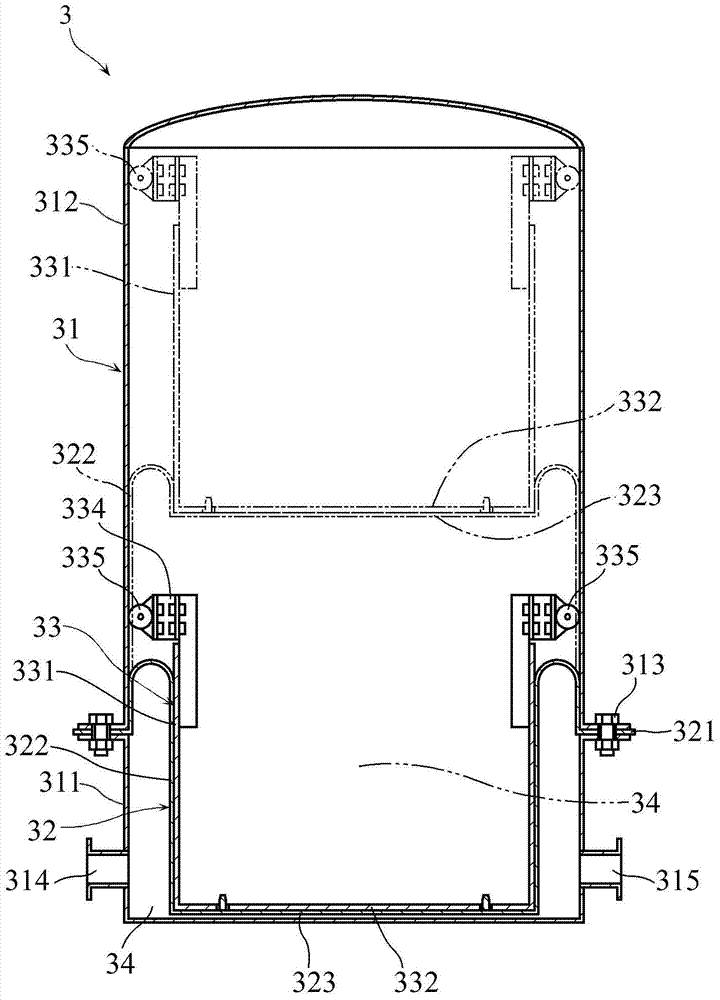

[0165] The adsorption towers 20A, 20B, and 20C used in this example are all made of stainless steel, have a cylindrical shape (with an inner diameter of 37 mm, and an inner dimension height of 1000 mm), and have a capacity of about 1 dm 3 . Each adsorption tower is filled with 1dm 3 LiX-type zeolites were used as adsorbents. Regarding the gas holder, use Figure 7 The shown ball type (capacity variable) accumulator 3A has a capa...

Embodiment 2

[0168] In the present embodiment, the operating conditions of the PSA device and the PSA method are the same as in Example 1, but the waste gas derived from the adsorption towers 20A, 20B, and 20C in the cleaning (second cleaning) process is discharged outside the system, and the remaining waste gas { In the cleaning (first cleaning) process (steps 1, 5, 9) and the countercurrent decompression process (steps 4, 8, 12), the exhaust gases derived from the adsorption towers 20A, 20B, and 20C are all added to the adsorption tower 20A. , 20B, 20C before the pre-treatment of the mixed gas, recirculation. The gas volume of the recirculation gas at this time is 145Ndm 3 / h, the composition of the recycle gas is 98.47 mol % of argon, 0.05 mol % of carbon monoxide, 1.02 mol % of carbon dioxide, and 0.47 mol % of nitrogen. The mixed gas with recirculation gas will be added (new pre-treated gas 885Ndm 3 / h and recycle gas 145Ndm 3 / h) at 1030Ndm3 The flow rate of / h is continuously supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com