Composite-material braided prefabricated filling belt and preparation method of composite-material braided prefabricated filling belt

A technology of composite materials and filling tapes, which can be applied to cladding optical fibers, optical waveguides and light guides, etc., and can solve the problems of low survival rate of grating optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

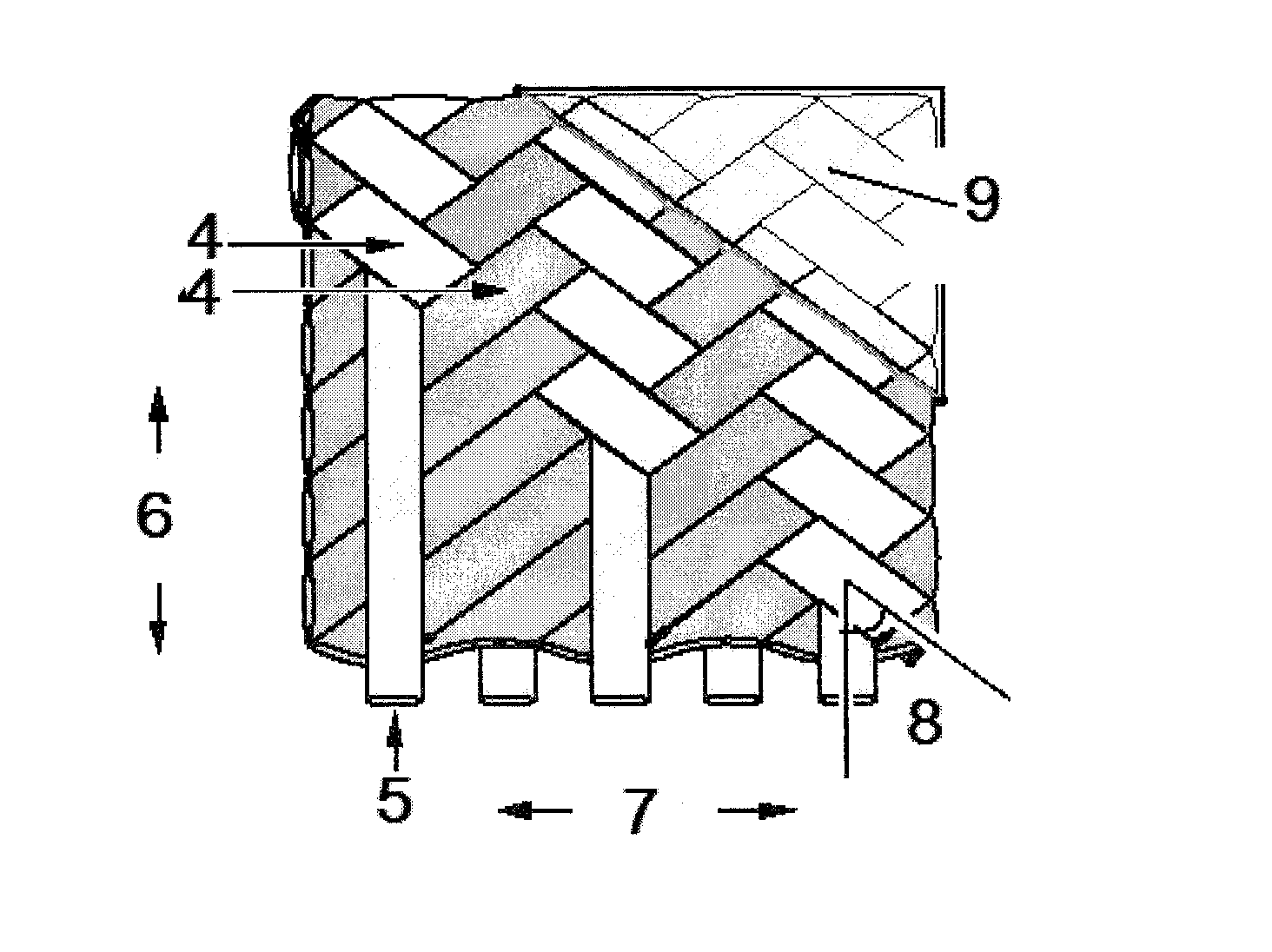

[0034] The specific operation steps of the preparation method of the composite material weaving prefabricated filling belt with sensing function concurrently according to the present invention are as follows:

[0035] (1) Select the filling amount of fiber yarn: based on the standardized overall structure and shape and size of the triangular area of the composite material structural part, and use the fiber volume fraction of the composite material structural part to design the fiber yarn used in the triangular area of the composite material part The total number of fiber bundles N, select fiber yarns with fiber bundles of N / 20 to 4N / 5 as the core material consumption, and the rest as the cladding fiber yarn consumption;

[0036] (2) Preparation of core material: first prepare a non-reactive sizing agent solution with a mass percentage concentration of 1%wt. to 20%wt., and spray or brush the non-reactive sizing agent solution on the surface of the fiber yarn for the core mat...

Embodiment 1

[0044] (1) Take 2 bundles of 12K T300 carbon fiber bundles as the core material, and spray a small amount (about 1 / 100 to 4 / 100 by mass percentage) of epoxy sizing agent for pretreatment. The molding process is at 65°C and under vacuum-assisted conditions Keep for 20min;

[0045] (2) Take 9 bundles of 12K T300 carbon fiber bundles, and carry out two-dimensional two-way weaving according to the standard weaving process on the outside of the above core material;

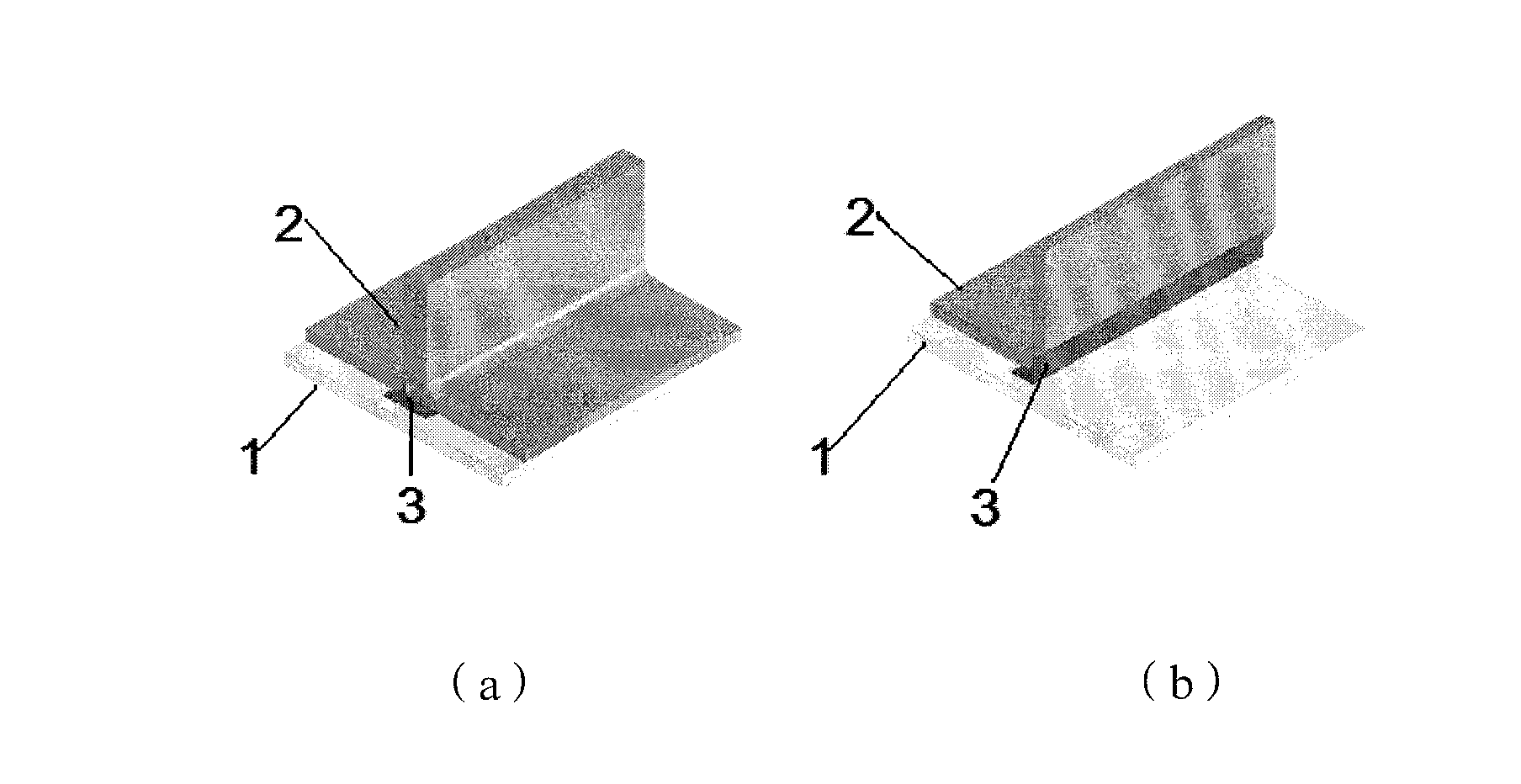

[0046] (3) On the outer surface of the braid, a small amount (about 1 / 100 to 4 / 100 by mass) is sprayed with a commercial epoxy setting agent, and after proper volatilization, it is continuously stretched axially into a simple equilateral triangular die ( see figure 1 a), the temperature of the die is matched with the sizing agent, so that the braid is shaped as a prefabricated braid of equi-arc triangle, stand-by;

[0047] (4) Similar to the above point (3), but changing the equal-arc triangle die into a right-angled...

Embodiment 2

[0049] The difference between this implementation example and embodiment 1 is that the forming die is changed to an equilateral triangle die and is a right angle arc chord triangle die (see figure 1 b), and the prefabricated braid of the right-angled arc-chord triangle that wraps the sensing grating optical fiber inside the core material, ready for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com