A kind of pressure-resistant flexible cable and its preparation process

A flexible cable and flexible technology, applied in the direction of cable/conductor manufacturing, insulated cable, bendable cable, etc., can solve the problems that the circuit cannot work normally, affect the laying of finished cables, and harden the material, and achieve good flexibility. Guarantee the effect of application safety, flexibility and construction improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

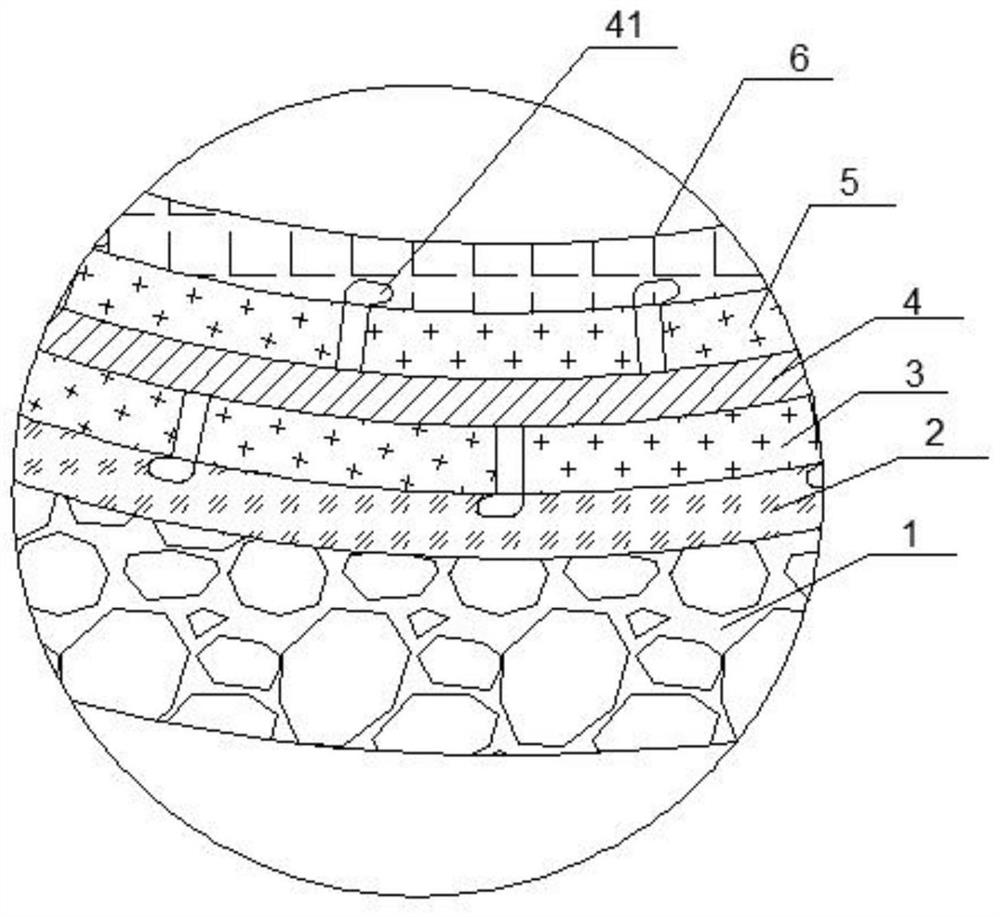

[0036] The short glass fiber doping amount in the insulating layer is 5.5wt% of the mass of the fluorine-containing high polymer, and the fluorine-containing high polymer is polytetrafluoroethylene, ethylene-tetrafluoroethylene copolymer, tetrafluoroethylene-hexafluoropropylene copolymer combination.

[0037] The surface metallization of the shielding layer is nickel-plated metal, and the metal plating amount is 0.55g / L graphite fiber.

[0038] The rare earth in the primary skeleton network layer is a composition of Y, Sm, Ce, and Sc, wherein the mass content of Y is not less than 30wt% of the total mass of rare earths, and the mass content of Sm is not less than 25wt% of the total mass of rare earths; The loading of rare earth in the carbon fiber is 14.3wt%, and the weight ratio of the rare earth modified carbon fiber is 6wt% of the magnesium alloy.

[0039] The mass ratio of glass fiber to carbon fiber in the secondary skeleton network layer is 1:1.5, and the total doping r...

Embodiment 2

[0042] The short glass fiber doping amount in the insulating layer is 6wt% of the mass of the fluorine-containing high polymer, and the fluorine-containing high polymer is a combination of polytetrafluoroethylene, ethylene-tetrafluoroethylene copolymer, and tetrafluoroethylene-hexafluoropropylene copolymer thing.

[0043] The surface metallization of the shielding layer is nickel-plated metal, and the metal plating amount is 0.5g / L graphite fiber.

[0044] The rare earth in the primary skeleton network layer is a combination of Y, Sm, Ce, and Sc, wherein the mass content of Y is not less than 30wt% of the total mass of rare earths, and the mass content of Sm is not less than 25wt% of the total mass of rare earths; The loading of rare earth in the carbon fiber is 15.1wt%, and the weight ratio of the rare earth modified carbon fiber is 4.6wt% of the magnesium alloy.

[0045] The mass ratio of glass fiber to carbon fiber in the secondary skeleton network layer is 1:1.8, and the ...

Embodiment 3

[0048] The short glass fiber doping amount in the insulating layer is 6.5 wt % of the mass of the fluorine-containing high polymer, and the fluorine-containing high polymer is a composition of polytetrafluoroethylene, polyvinylidene fluoride, and ethylene-chlorotrifluoroethylene copolymer.

[0049] The surface metallization in the shielding layer is metal-plated copper on the surface, and the metal plating amount is 0.6g / L graphite fiber.

[0050] The rare earth in the primary skeleton network layer is a combination of Y, Sm, Ce, and Sc, wherein the mass content of Y is not less than 30wt% of the total mass of rare earths, and the mass content of Sm is not less than 25wt% of the total mass of rare earths; The rare earth loading in the carbon fiber is 13wt%, and the weight ratio of the rare earth modified carbon fiber is 5.5wt% of the magnesium alloy.

[0051] The mass ratio of glass fiber to carbon fiber in the secondary skeleton network layer is 1:1.7, and the total doping ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com