Analysis method of bias magnet characteristic of electric sheet

An analysis method and technology for electrical steel sheets, applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of difficult control technology, reduced overall reliability of equipment, and difficulty in estimating the working performance of ferromagnetic materials. Simple process and ideas, excellent performance, and cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

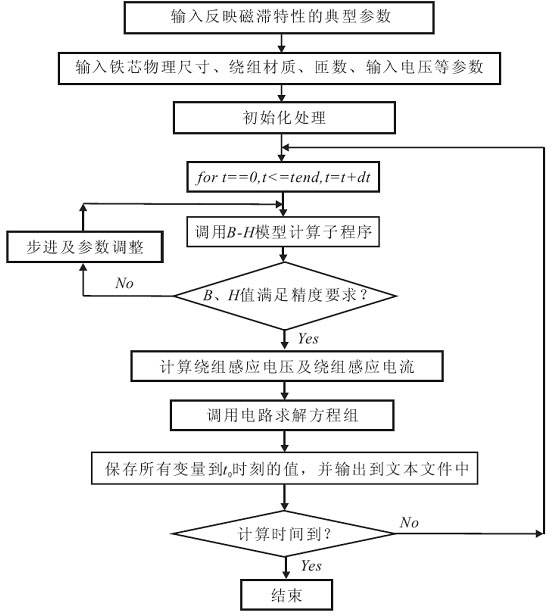

[0039] The structure diagram of the present invention is as figure 1 Shown, the analytical method of electrical steel sheet magnetic bias characteristic of the present invention, comprises the steps:

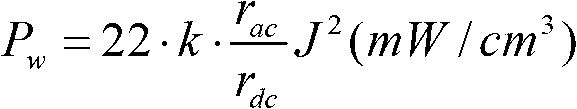

[0040] 1) Calculate the leakage inductance L and self resistance r of the core winding according to the design parameters L , where the leakage inductance is selected according to 3% to 5% of the theoretical inductance design parameters, and the resistance is selected according to r L =ρ*l / S to calculate, where: ρ is the resistivity of the winding material, l is the total length of the winding, the cross-sectional area of the S winding wire, the result obtained by using this formula is the DC resistance, under the condition of AC operation , then the skin effect should be considered, and the DC resistance rdc , AC resistance r ac , wire current density J, power loss per unit volume of winding P w , and the relationship between the filling coefficient k is:

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com