Metal oxide coated lithium nickel manganese oxide material, preparation method of metal oxide coated lithium nickel manganese oxide material and lithium ion battery

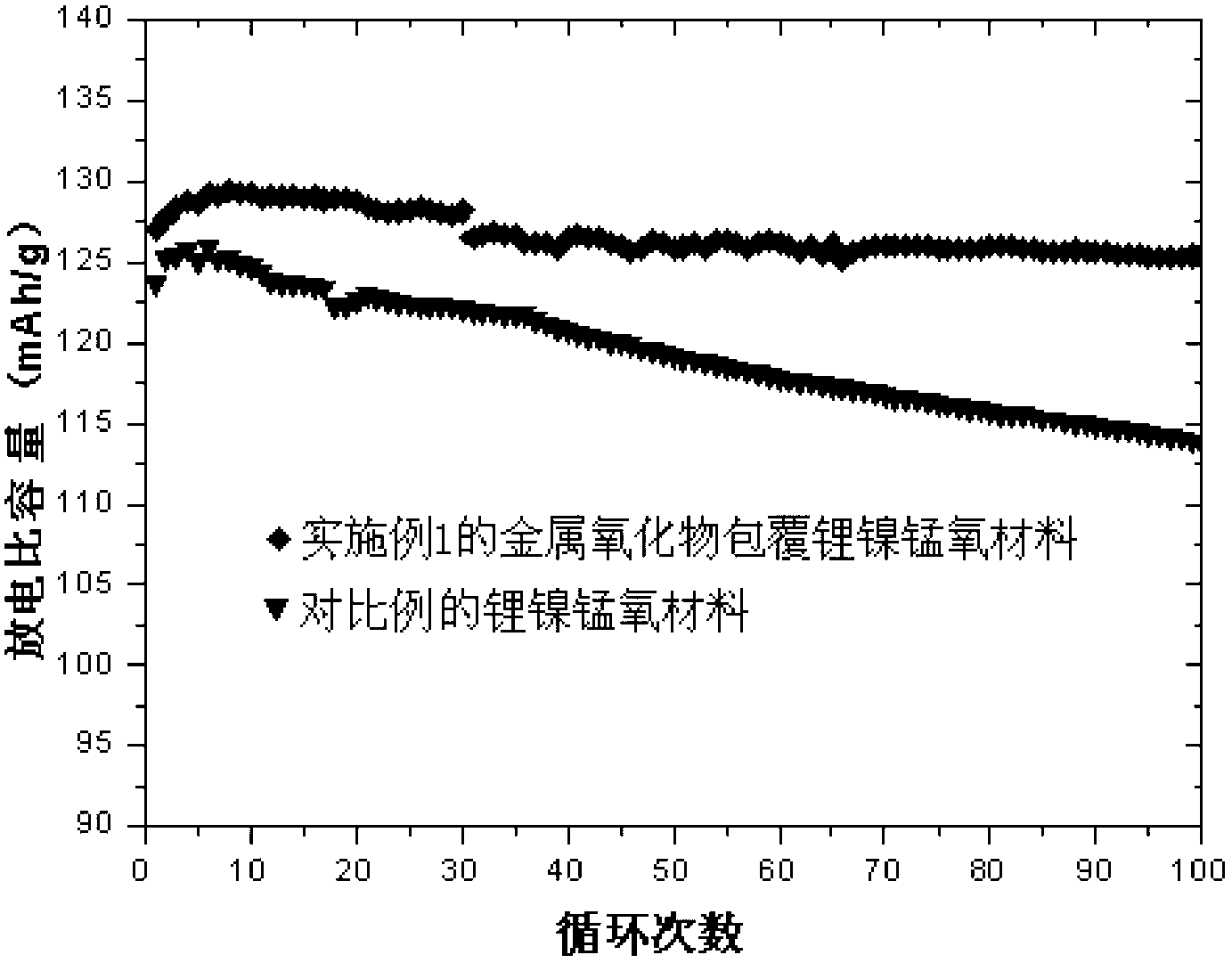

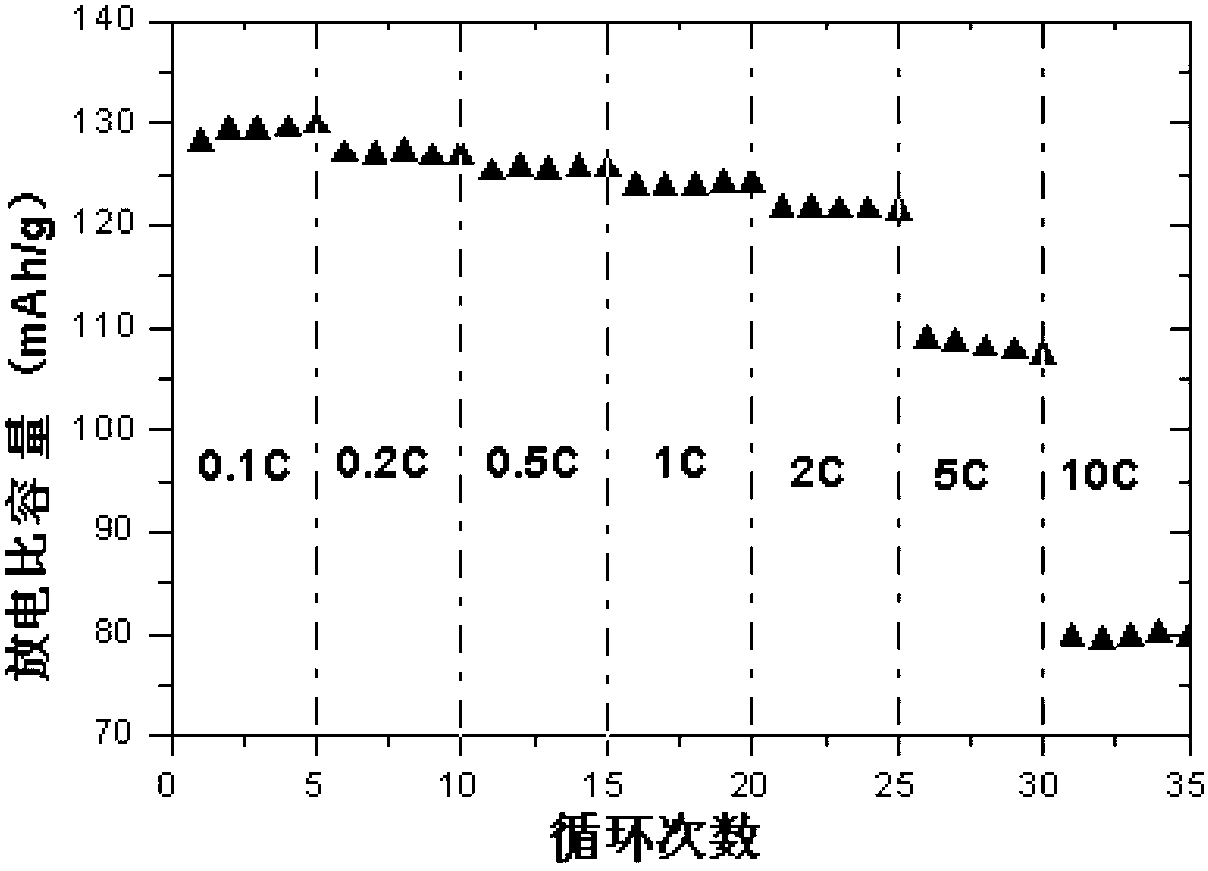

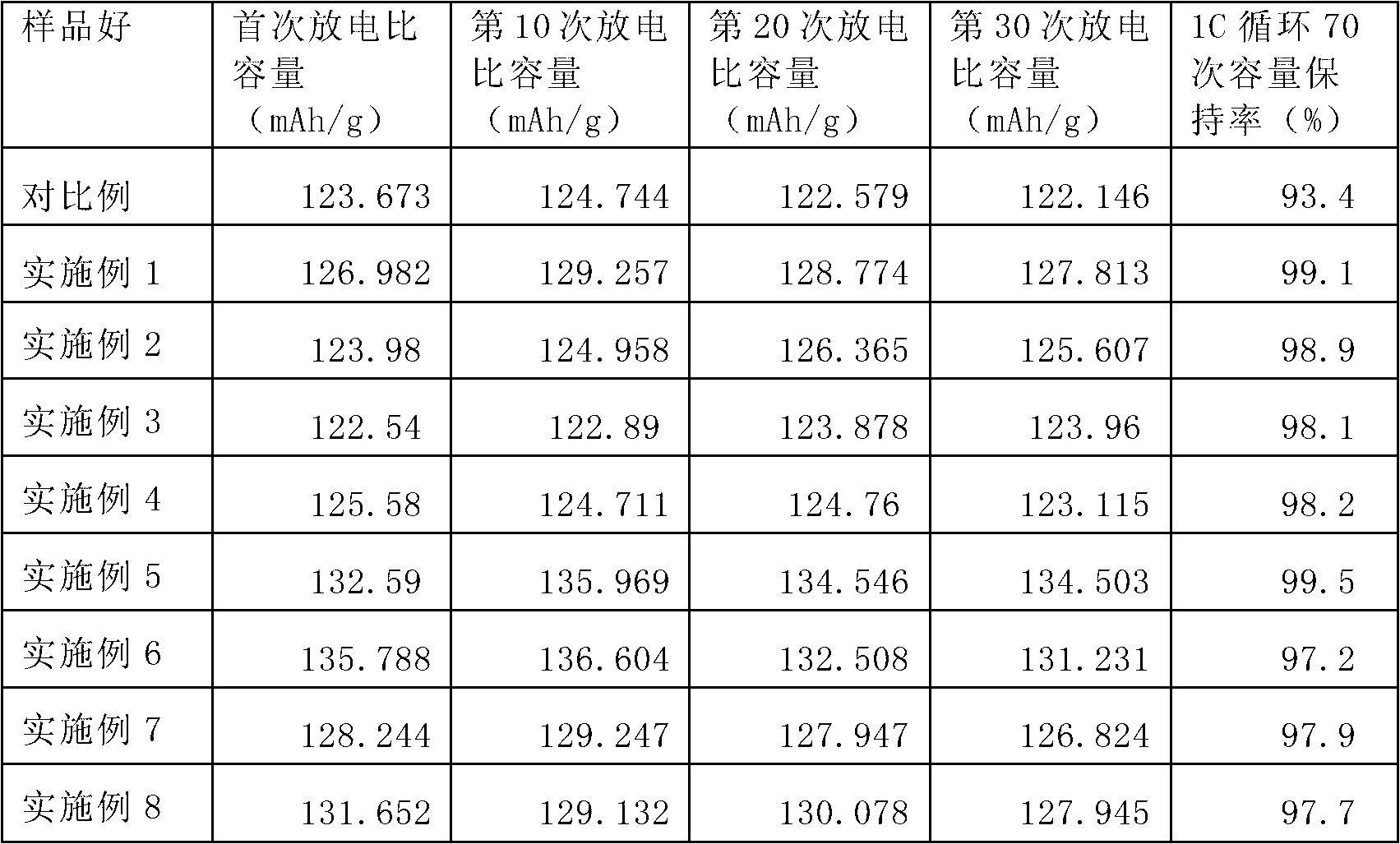

A metal ion and oxide technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of incompatibility with large-scale production, poor material cycle performance, etc., and achieve adaptation to large-scale production, cycle stability and rate. The effect of good performance and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a metal oxide-coated LiNi 0.5 mn 1.5 o 4 The preparation method of material, it comprises the following steps:

[0037] Step 1, prepare LiNi by the method for comparative example 0.5 mn 1.5 o 4 Material.

[0038] Step 2, weigh 0.4225g of MnSO 4 ·H 2 O is made into an aqueous solution with a metal ion concentration of 0.5mol / L, and 7.0274g of the above-mentioned LiNi is added thereto 0.5 mn 1.5 o 4 Material. Na as precipitant 2 CO 3 It is configured into a precipitant solution with a mass concentration of 0.8%, and in a stirring state, the precipitant solution is added dropwise to the above-mentioned aqueous solution, wherein Na 2 CO 3 The consumption (amount of substance) is 3.5% more than the amount needed to make all the metal ions in the aqueous solution precipitate, that is, the precipitant is excessive by 3.5% to ensure that the metal ion precipitation is complete. After standing for 2 hours, the precipitate was collected, ce...

Embodiment 2

[0044] This embodiment provides a metal oxide-coated LiNi 0.5 mn 1.5 o 4 The preparation method of material, it comprises the following steps:

[0045] Step 1, prepare LiNi by the method for comparative example 0.5 mn 1.5 o 4 Material.

[0046] Step 2, weigh 0.2451g of MnCl 2 4H 2 O is made into an aqueous solution with a metal ion concentration of 1mol / L, and 8.6067g of the above-mentioned LiNi is added thereto 0.5 mn 1.5 o 4 Material. K will be used as precipitant 2 CO 3 It is configured into a precipitant solution with a mass concentration of 1.2%. In a stirring state, the precipitant solution is added dropwise to the above aqueous solution, wherein K 2 CO 3 (That is, the amount of the precipitating agent) (the amount of the substance) is over 3% to ensure that the metal ion precipitation is complete. After standing for 2 hours, the precipitate was collected, centrifuged, washed 4 times, and dried at 110°C for 12 hours. In an air atmosphere, the precipitate ...

Embodiment 3

[0049] This embodiment provides a metal oxide-coated LiNi 0.5 mn 1.5 o 4 The preparation method of material, it comprises the following steps:

[0050] Step 1, prepare LiNi by the method for comparative example 0.5 mn 1.5 o 4 Material.

[0051] Step 2, take by weighing 0.179g of Mn(NO 3 ) 2 Make an aqueous solution with a metal ion concentration of 0.05mol / L, add 17.3004g of the above-mentioned LiNi to it 0.5 mn 1.5 o 4 Material. (NH 4 ) 2 CO 3 Be configured into a precipitant solution with a mass concentration of 0.09%, and in a stirring state, add the precipitant solution dropwise to the above aqueous solution, wherein (NH 4 ) 2 CO 3 (That is, the amount of precipitant) (the amount of substance) is over 5% to ensure that the precipitation of metal ions is complete. After standing for 2 hours, the precipitate was collected, centrifuged, washed 4 times, and dried at 110°C for 12 hours. In a pure oxygen atmosphere, the precipitate was heated to 450°C at a heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com