Method for repairing oxygen defect in preparation process of spinel lithium manganate as lithium-ion cathode material

A cathode material, lithium manganate technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as capacity decay and few structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh 693g of lithium carbonate, 101g of aluminum hydroxide, and 3192g of electrolytic manganese dioxide and put them into a horizontal ball mill tank for rough mixing for 30 minutes.

[0023] (2) Sieve out the zirconium balls, put them into an automatic granulator and mix them finely for 20 minutes.

[0024] (3) After fine mixing, directly add 5% PVA in the granulator to granulate, and the moisture content in the material is 13%.

[0025] (4) After the granulated material is dried, pour it into the material bowl and put it into the atmosphere furnace for one-time calcination.

[0026] (5) After the primary sintering is completed, the particles are disintegrated, 35 g of lithium carbonate is added, mixed evenly, and the secondary calcination is carried out to obtain the final powder product.

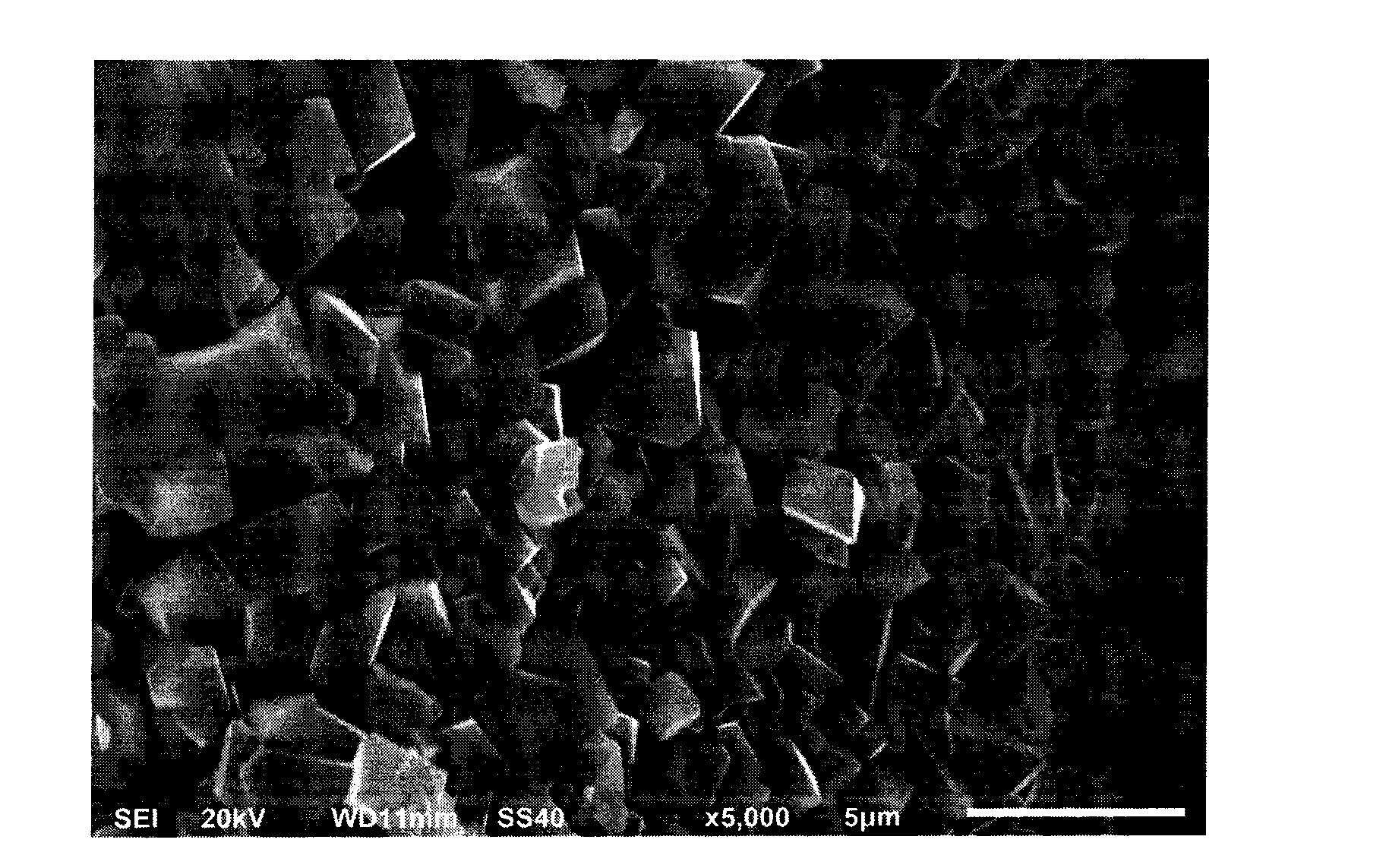

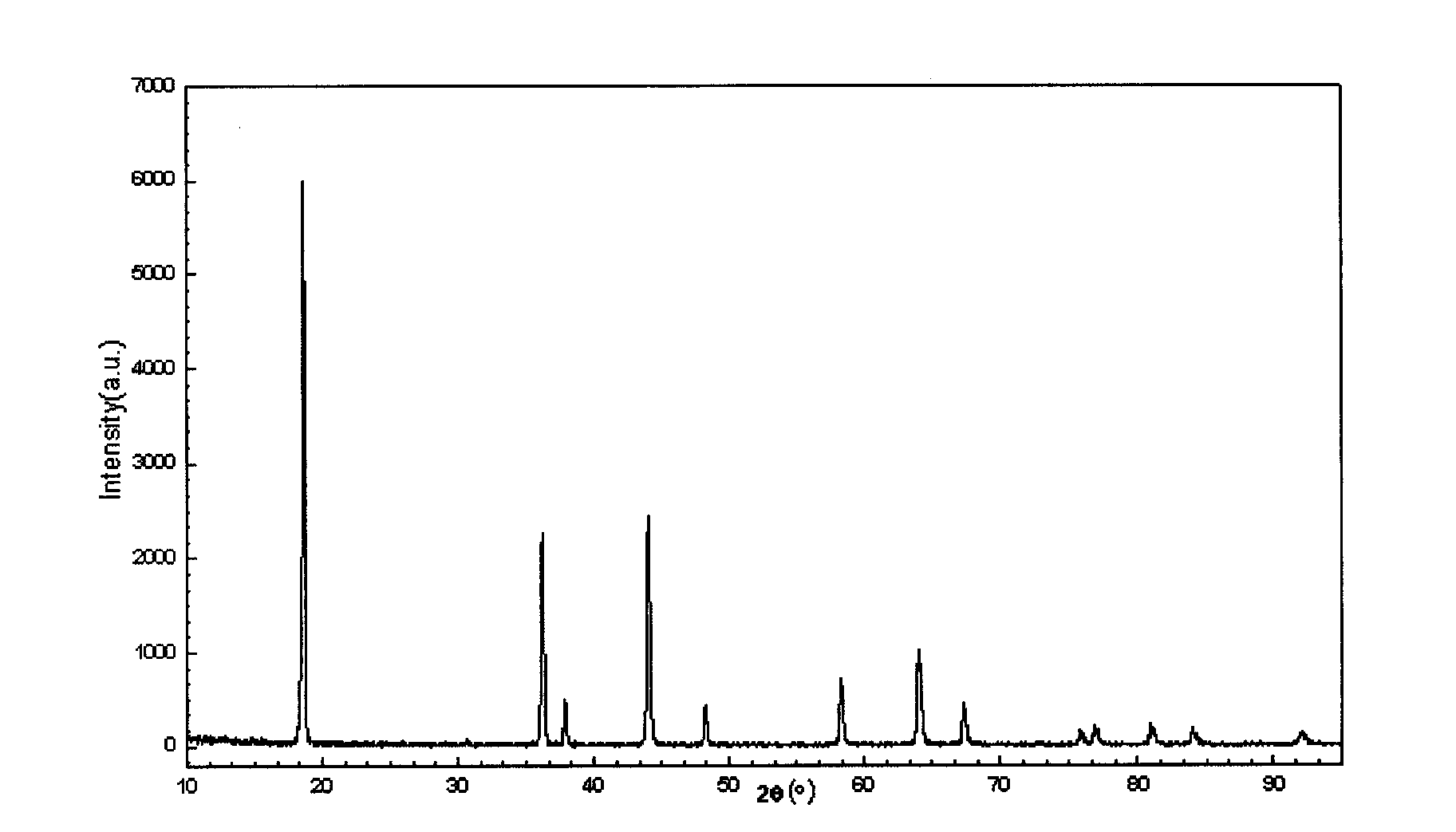

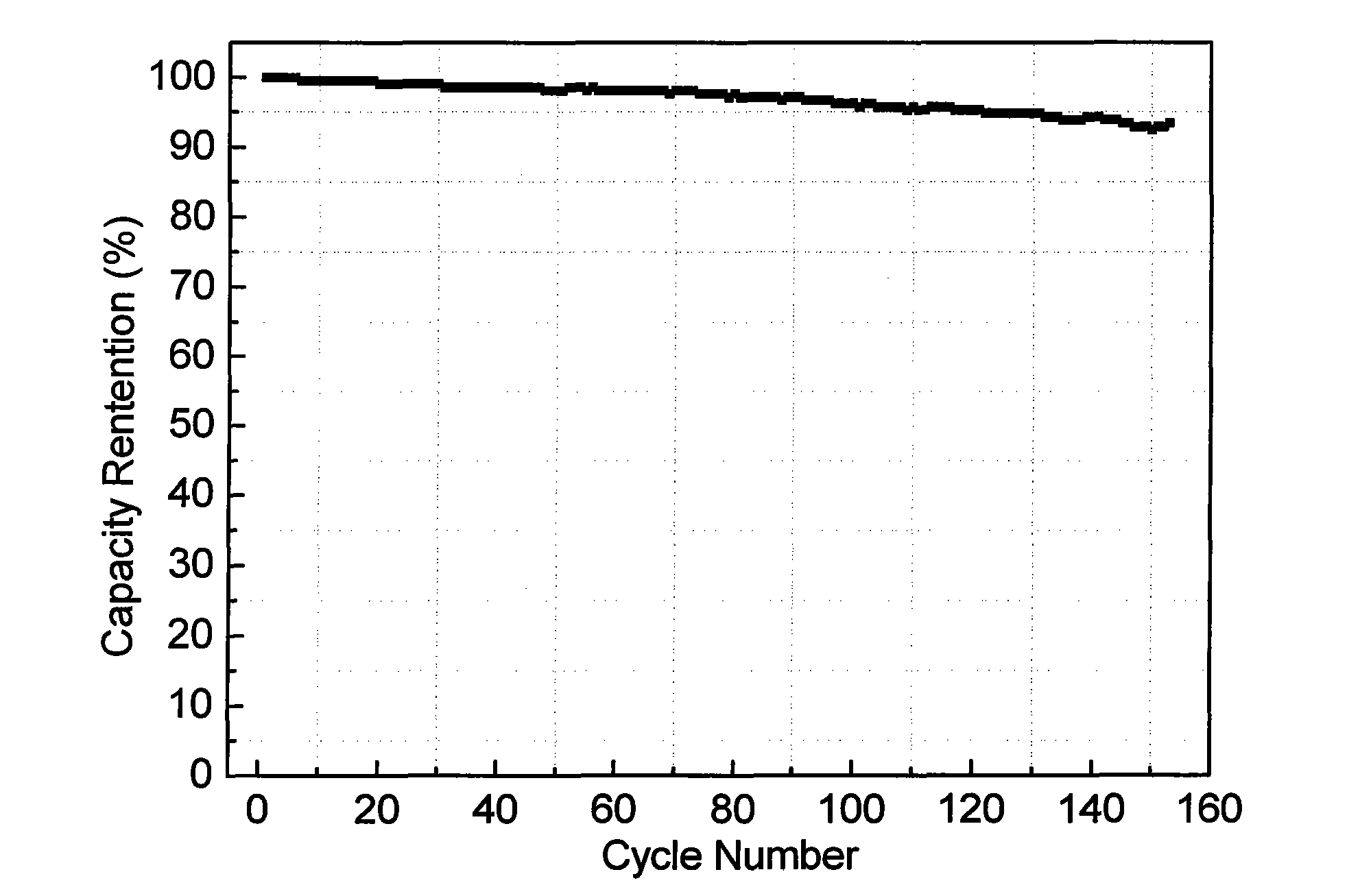

[0027] (6) Do XRD, SEM and electrical performance analysis tests on the powder, the results are as follows Figure 1-Figure 4 shown.

Embodiment 2

[0029] (1) Weigh 693g of lithium carbonate, 101g of aluminum hydroxide, and 3192g of electrolytic manganese dioxide and put them into a horizontal ball mill tank for rough mixing for 30 minutes.

[0030] (2) Sieve out the zirconium balls, put them into an automatic granulator and mix them finely for 20 minutes.

[0031] (3) After fine mixing, directly add 3% PVA in the granulator to granulate, and the moisture content in the material is 16%.

[0032] (4) After the granulated material is dried, pour it into the material bowl and put it into the atmosphere furnace for one-time calcination.

[0033] (5) After the primary sintering is completed, the particles are disintegrated, 35 g of lithium carbonate is added, mixed evenly, and the secondary calcination is carried out to obtain the final powder product.

[0034] (6) Test the product.

Embodiment 3

[0036] (1) Weigh 728g of lithium carbonate, 101g of aluminum hydroxide, and 3192g of electrolytic manganese dioxide and put them into a horizontal ball mill tank for rough mixing for 30 minutes.

[0037] (2) Sieve out the zirconium balls, put them into an automatic granulator and mix them finely for 20 minutes.

[0038] (3) After fine mixing, directly add 5% PVA in the granulator to granulate, and the moisture content in the material is 13%.

[0039] (4) After the granulated material is dried, pour it into the material bowl and put it into the atmosphere furnace for one-time calcination.

[0040] (5) After the primary sintering is completed, the particles are disintegrated and subjected to secondary calcination to obtain the final powder product.

[0041] (6) Analyze and test the powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com