Coherent control array structure of micro lens integrated VCSELs (Vertical-Cavity Surface-Emitting Lasers)

A technology of vertical cavity surface emission and array structure, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of low coherence of devices and large divergence angle of outgoing light, and achieve improved coherence, quality and good space. and temporal coherence effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structure of the present invention will be further described in detail below in conjunction with the embodiments given in the accompanying drawings.

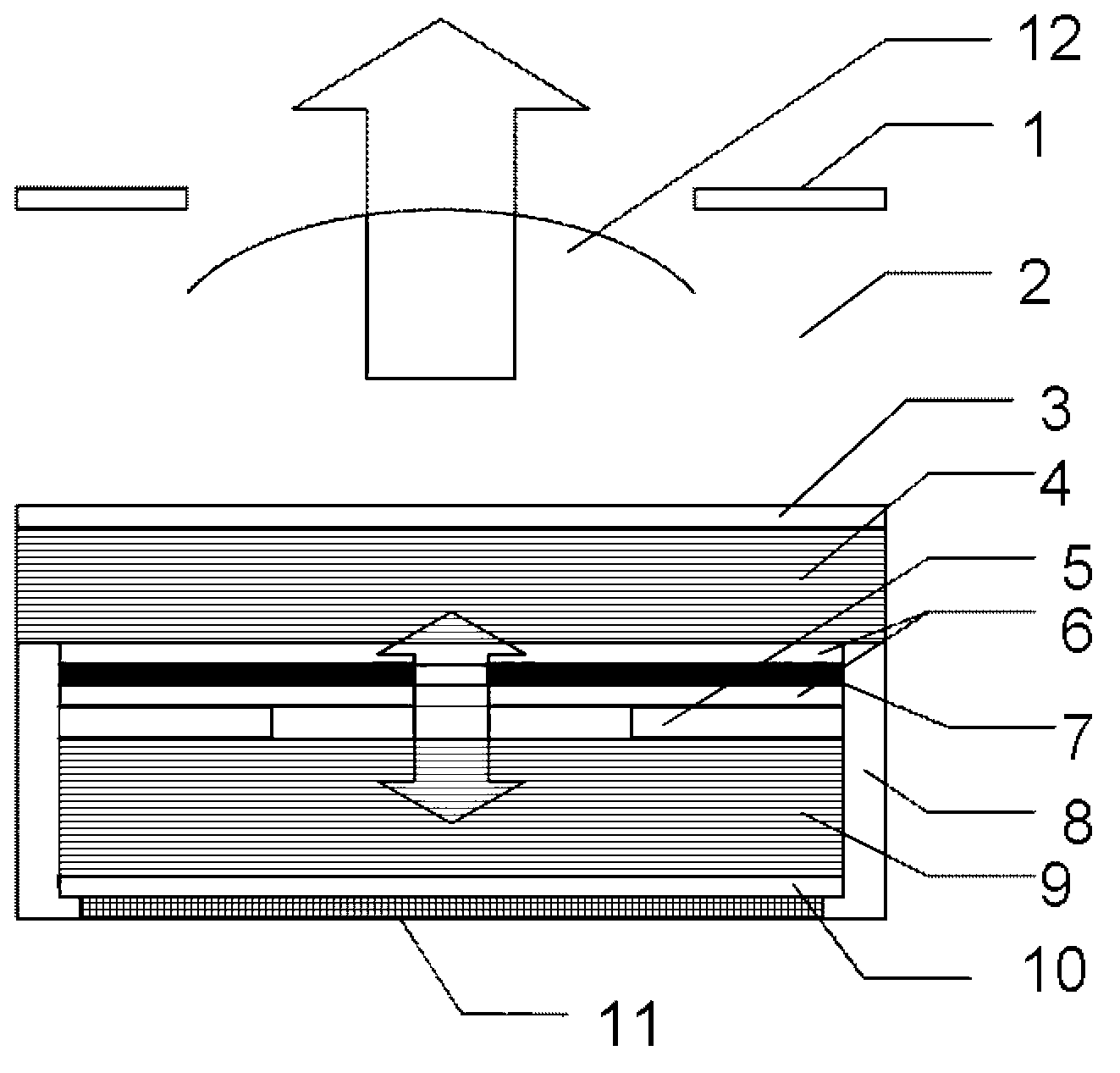

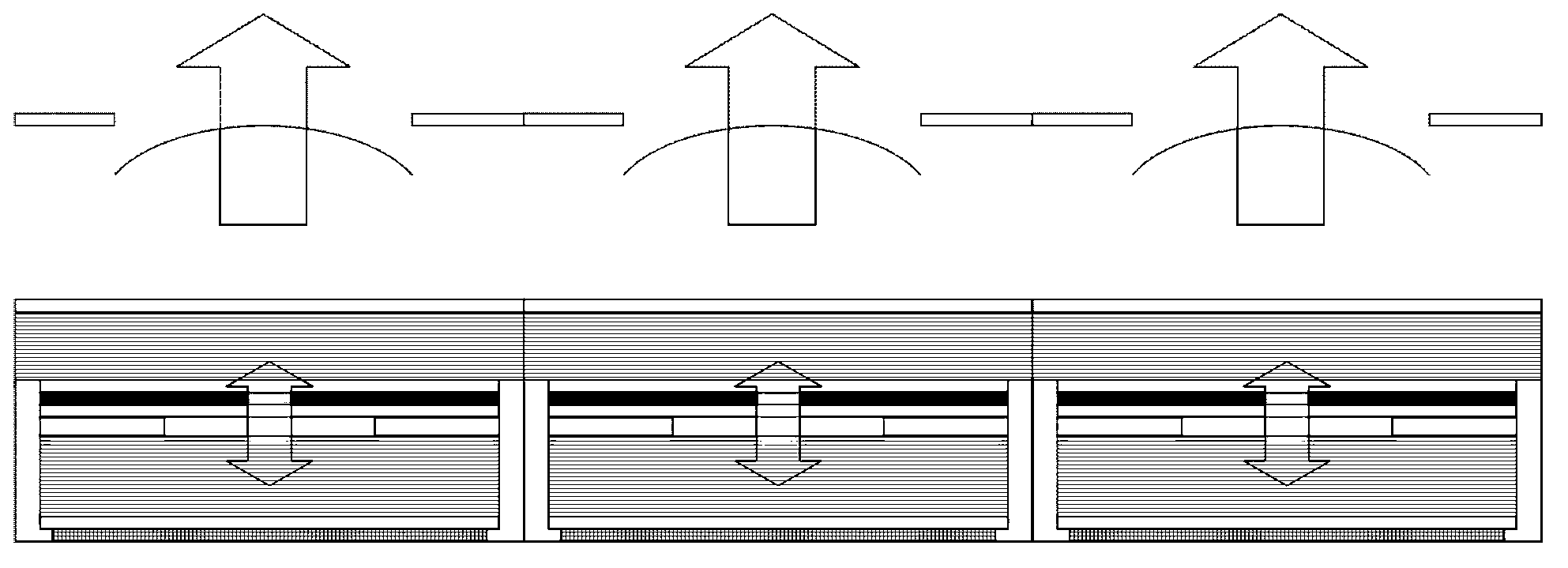

[0014] like figure 1 , figure 2 As shown, the coherent control array structure of the microlens integrated vertical cavity surface emitting laser of the present invention includes a plurality of microlens integrated vertical cavity surface emitting lasers, and each microlens integrated vertical cavity surface emitting laser is an n-plane electrode 1 from top to bottom , substrate 2, buffer layer 3, n-type DBR layer 4, passivation layer 5, active region (from top to bottom the active region includes upper space layer 6-1, gain medium layer 7 and lower space layer 6-2 ), p-type DBR layer 9, ohmic contact layer 10 and metal grid electrode 11; the substrate 2 is etched into microlenses 12;

[0015] combine figure 1 The growth process of each single tube structure in the coherent control array structure of the microlen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com