A multifunctional charger

A charging machine and multi-functional technology, applied in the direction of collectors, electric vehicles, electrical components, etc., can solve the problems of cooling off for a certain period of time, large power grid impact, poor initial charging quality, etc., to ensure accuracy and prolong service life. , the effect of improving the quality of charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

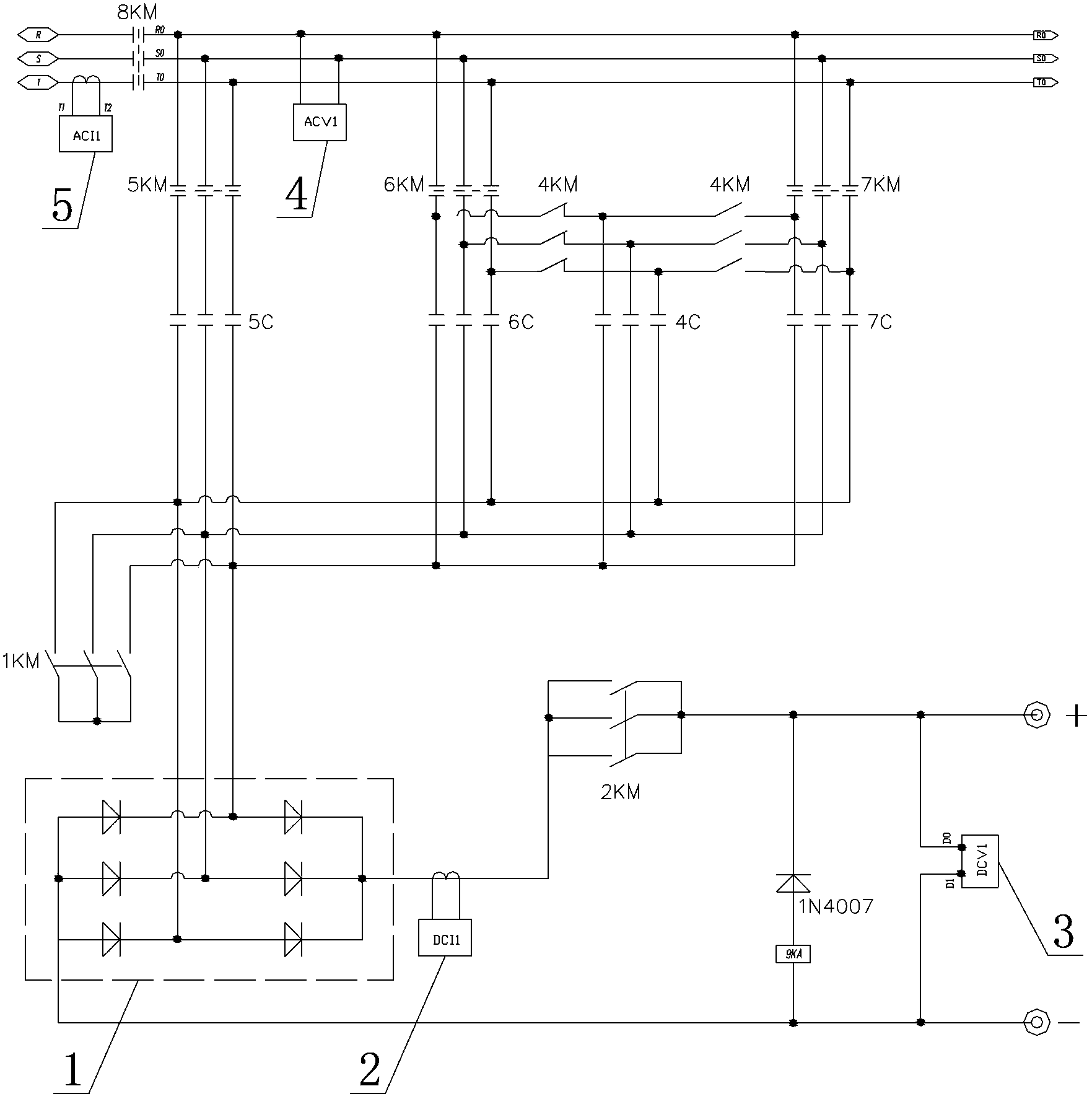

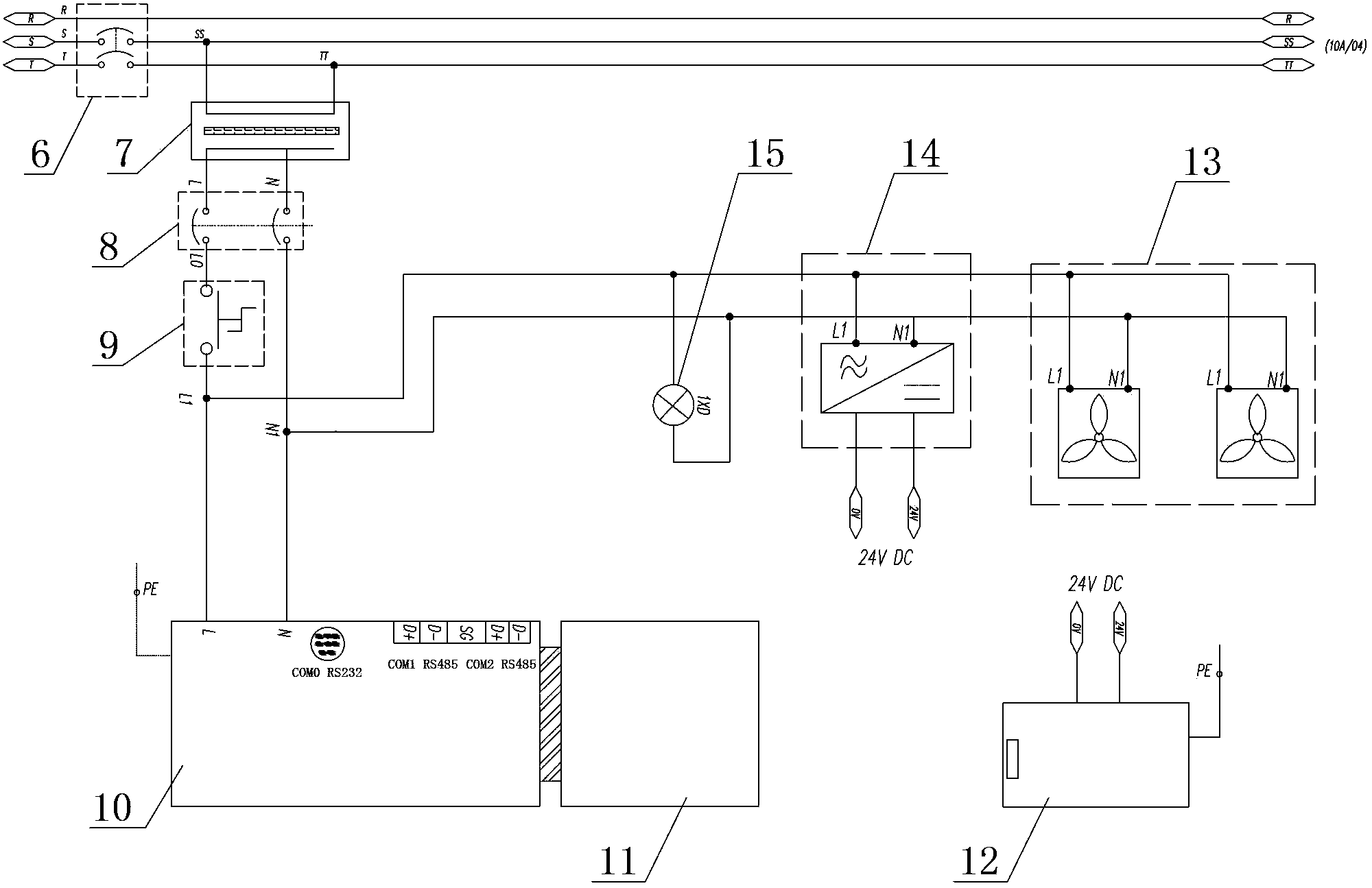

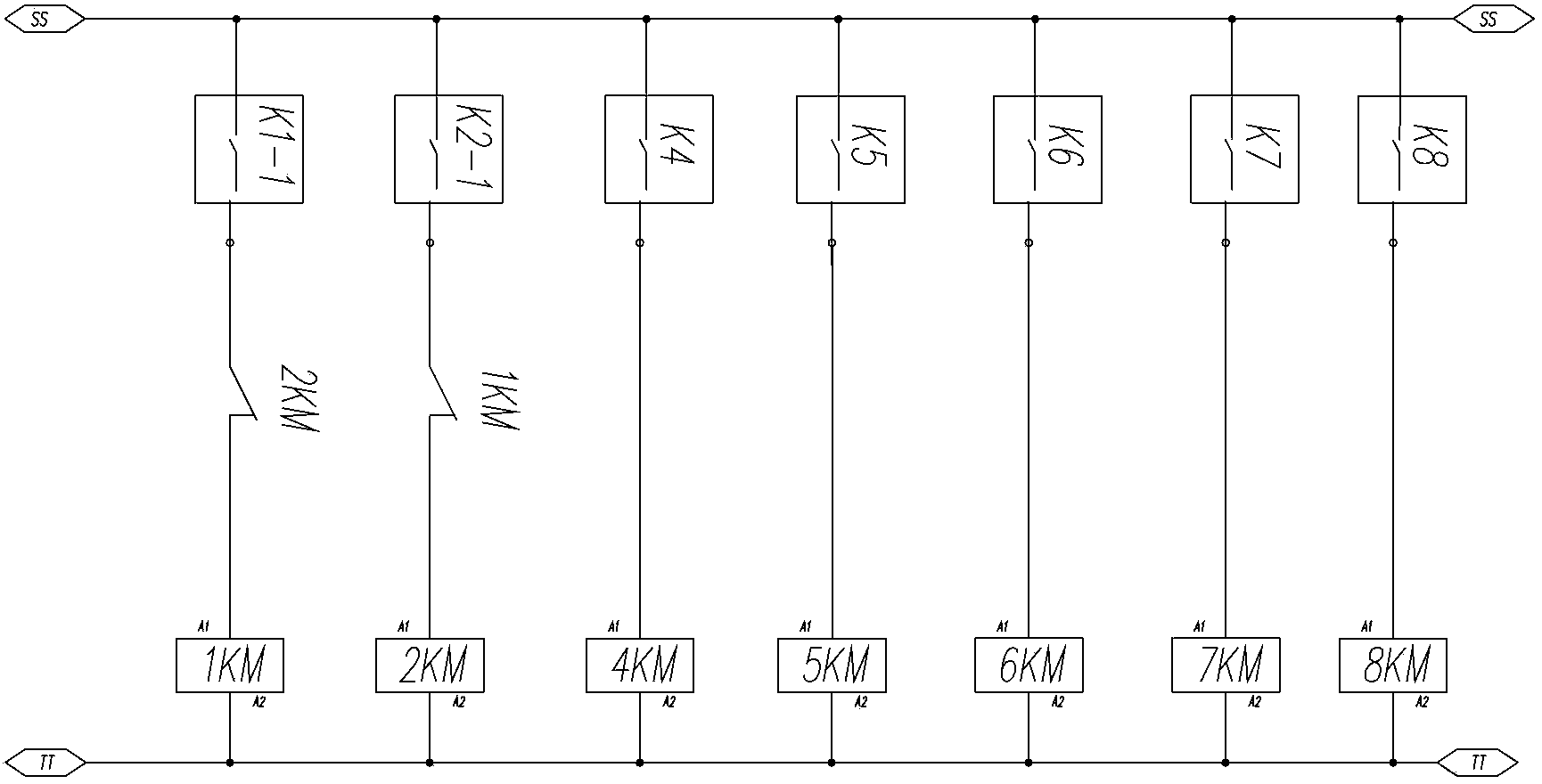

[0036] like Figure 1 to Figure 7 As shown, a multifunctional charger includes a charging circuit, a compensation circuit, a rectification circuit, an intelligent control system, a compensation contactor 1KM, a charging contactor 2KM, an AC contactor 8KM and a reverse relay 9KA. The rectification circuit consists of three The phase rectification full bridge 1 is composed of the AC arm of the three-phase rectification full bridge 1 respectively connected to the upper end of the compensation contactor 1KM and one end of the capacitor bank 4C, 5C, 6C, 7C, and the negative terminal of the DC output arm is connected to the negative pole of the DC output circuit of the charger After the positive pole of the DC output arm is connected in series with the 2KM main contact of the charging contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com