Tablets comprising olmesartan medoxomil and method for preparing same

A technology of olmesartan medoxomil and tablets, which is applied in the field of western medicine preparations, can solve the problems of dissolution rate, low dissolution rate, and the inability to solve the problems of the taste of active ingredients, and achieve high dissolution rate, good taste, and improved stability and dissolution rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of embodiment 1 olmesartan medoxomil tablet

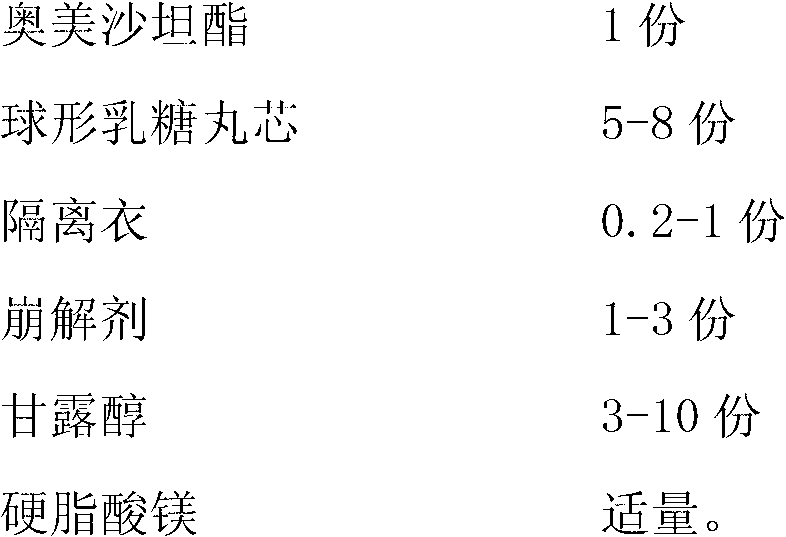

[0022] Prescription composition:

[0023]

[0024] Preparation Process:

[0025] (1) Transfer the 400-micron spherical lactose pellet core to the fluidized bed system, add the prescribed amount of olmesartan medoxomil to 80% ethanol solution to dissolve, and spray the olmesartan medoxomil solution into the spherical lactose pellet Olmesartan medoxomil pellets were prepared in a fluidized bed with a core. Among them: during the pelletizing process, the inlet temperature is 35°C, the outlet temperature is 30°C, and the product temperature is 30°C; during the drying process, the inlet temperature is 45°C, the outlet temperature is 35°C, and the product temperature is 35°C; the spray speed is 6ml / min, and the spray pressure is 3bar.

[0026] (2) Weigh polyvinyl alcohol, polyethylene glycol triethyl citrate and talcum powder according to the weight ratio = 1:0.2:0.3, mix them, dissolve them in purified water...

Embodiment 2

[0028] The preparation of embodiment 2 olmesartan medoxomil tablets

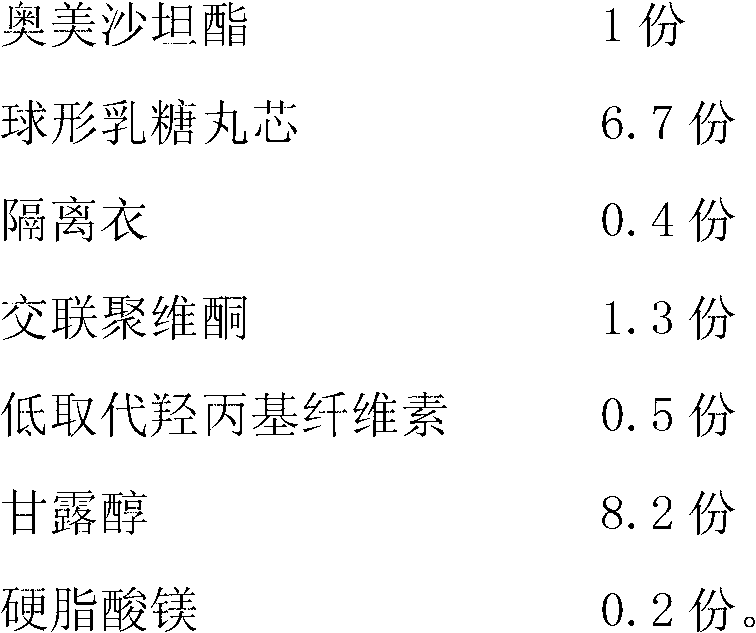

[0029] Prescription composition:

[0030]

[0031] Preparation Process:

[0032] (1) Transfer the 400-micron spherical lactose pellet core to the fluidized bed system, add the prescribed amount of olmesartan medoxomil to 80% ethanol solution to dissolve, and spray the olmesartan medoxomil solution into the spherical lactose pellet Olmesartan medoxomil pellets were prepared in a fluidized bed with a core. Among them: during the pelletizing process, the inlet temperature is 35°C, the outlet temperature is 30°C, and the product temperature is 30°C; during the drying process, the inlet temperature is 45°C, the outlet temperature is 35°C, and the product temperature is 35°C; the spray speed is 6ml / min, and the spray pressure is 3bar.

[0033] (2) Weigh polyvinyl alcohol, polyethylene glycol triethyl citrate and talcum powder according to the weight ratio = 1:0.1:0.2, mix them, dissolve them in purified wate...

Embodiment 3

[0035] The preparation of embodiment 3 olmesartan medoxomil tablets

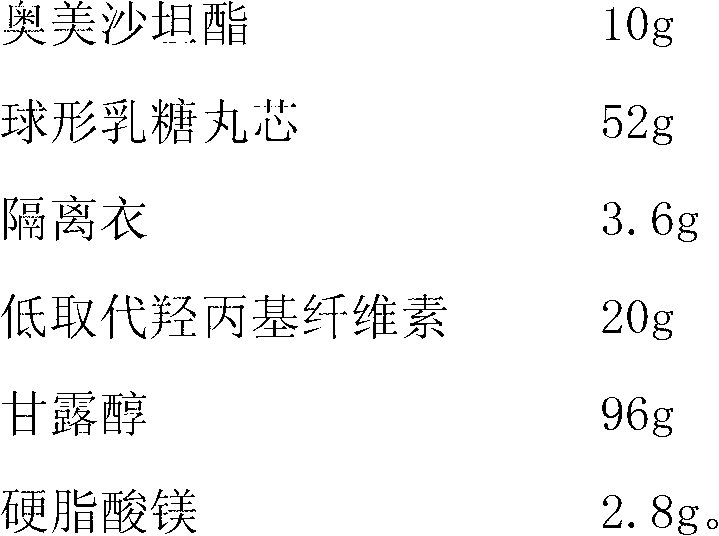

[0036] Prescription composition:

[0037]

[0038]

[0039] Preparation Process:

[0040] (1) Transfer the 400-micron spherical lactose pellet core to the fluidized bed system, add the prescribed amount of olmesartan medoxomil to 80% ethanol solution to dissolve, and spray the olmesartan medoxomil solution into the spherical lactose pellet Olmesartan medoxomil pellets were prepared in a fluidized bed with a core. Among them: during the pelletizing process, the inlet temperature is 35°C, the outlet temperature is 30°C, and the product temperature is 30°C; during the drying process, the inlet temperature is 45°C, the outlet temperature is 35°C, and the product temperature is 35°C; the spray speed is 6ml / min, and the spray pressure is 3bar.

[0041] (2) Weigh polyvinyl alcohol, polyethylene glycol triethyl citrate and talcum powder according to the weight ratio = 1:0.2:0.3, mix them, dissolve them in p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com