Variable-frequency oil gas recovery control system of fuel dispenser

A technology of control system and fuel dispenser, which is applied in special dispensing devices, packaging, dispensing devices, etc. It can solve problems such as waste of electric energy in recovery ratio, loss of oil and gas in oil tanks, and unreasonable problems, so as to increase flow rate, reduce the probability of error, and simplify The effect of the control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

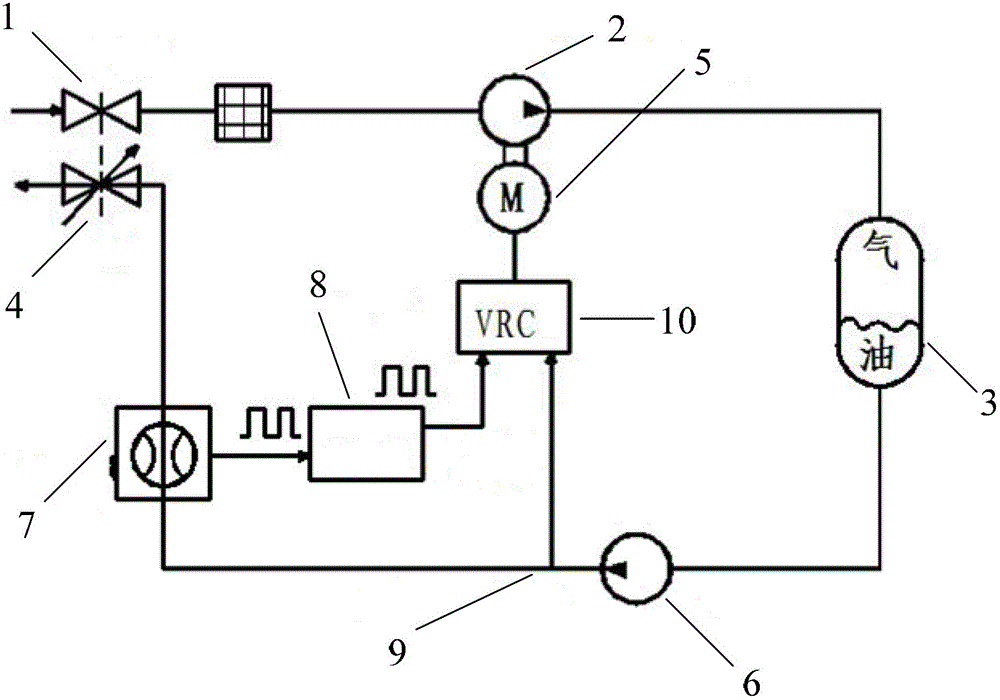

[0030] The structural diagram of the frequency conversion oil gas recovery control system of the fuel oil dispenser of the present invention is as follows figure 1 As shown, it includes a flow metering pulse sensor 8, a controller 10, a recovery motor 5, a vacuum oil vapor recovery vane pump 2, a return valve 1 arranged at the mouth of the refueling gun 4 and a temperature sensor 9 arranged on the refueling pipeline; Valve 1, vacuum oil and gas recovery vane pump 2, oil tank 3 and refueling pump 6 are connected sequentially; flow metering pulse sensor 8 is connected with flow meter 7 signal on the refueling pipeline, flow metering pulse sensor 8 is connected to controller 10, recovery motor 5 and The vane pump 2 for vacuum oil and gas recovery is signal-connected sequentially, and the recovery motor 5 adopts a variable-frequency motor; the temperature sensor 9 set between the fuel pump 6 and the flow meter 7 on the refueling pipeline in this system is connected to the controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com