Flocculant for low-residue drinking water treatment and preparation method thereof

A technology for drinking water treatment and low residue, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of uncontrollable raw material composition and poor product stability, and achieve easy control of raw material quality, stable product and low effluent turbidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

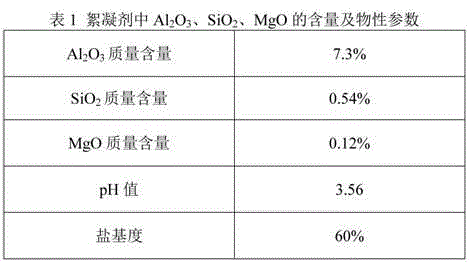

Embodiment 1

[0027] A flocculant for low-residue drinking water treatment is polymerized from water glass, magnesium chloride, aluminum sulfate, and sodium aluminate. The preparation method comprises the following steps:

[0028] 1) Dissolve the raw materials in water respectively to form SiO 2 Content is 8wt% water glass solution, MgO content is 10wt% magnesium chloride solution, Al 2 o 3 Aluminum sulfate solution with a content of 9 wt%, Al 2 o 3 Content is the sodium aluminate solution of 6.2 wt %;

[0029] 2) At room temperature, in a reaction kettle with a heating and stirring device, add 33.8g water glass solution, 6.0g magnesium chloride solution, wherein, SiO 2 : The mass ratio of MgO is 4.5:1, stir evenly, adjust the pH value to 9.5, and obtain a suspension containing white suspended matter;

[0030] 3) Add 285.6g of aluminum sulfate solution to the suspension, and then add 174.6g of sodium aluminate solution at a stirring speed of 7500rpm to obtain a mixed solution;

[0031...

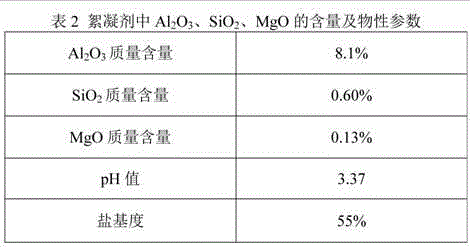

Embodiment 2

[0035] A flocculant for low-residue drinking water treatment is polymerized from water glass, magnesium chloride, aluminum sulfate, and sodium aluminate. The preparation method comprises the following steps:

[0036] 1) Dissolve the raw materials in water respectively to form SiO 2 Content is 8wt% water glass solution, MgO content is 10wt% magnesium chloride solution, Al 2 o 3 Aluminum sulfate solution with a content of 9 wt%, Al 2 o 3 Content is the sodium aluminate solution of 8.5 wt %;

[0037] 2) At room temperature, in a reaction kettle with a heating and stirring device, add 37.5g of water glass solution, 6.5g of magnesium chloride solution, wherein, SiO 2 : The mass ratio of MgO is 4.6:1, stir evenly, adjust the pH value to 10, and obtain a suspension containing white suspended matter;

[0038] 3) Add 326.7g of aluminum sulfate solution to the suspension, and then add 129.3g of sodium aluminate solution at a stirring speed of 7000rpm to obtain a mixed solution;

...

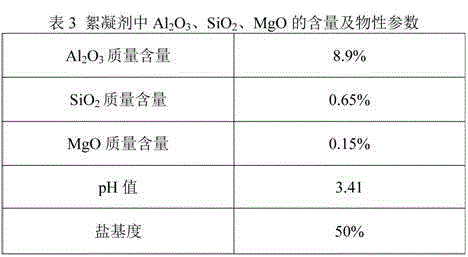

Embodiment 3

[0043] A flocculant for low-residue drinking water treatment is polymerized from water glass, magnesium sulfate, aluminum chloride, and sodium aluminate. The preparation method comprises the following steps:

[0044] 1) Dissolve the raw materials in water respectively to form SiO 2 Content is 8wt% water glass solution, MgO content is 10wt% magnesium sulfate solution, Al 2 o 3 Aluminum chloride solution with a content of 9 wt%, Al 2 o 3 Content is the sodium aluminate solution of 13.8wt%;

[0045]2) At room temperature, in a reaction kettle with a heating and stirring device, add 40.6g of water glass solution, 7.5g of magnesium sulfate solution, wherein, SiO 2 : The mass ratio of MgO is 4.3:1, stir evenly, adjust the pH value to 9.5, and obtain a suspension containing white suspended matter;

[0046] 3) Add 372.2g of aluminum chloride solution to the suspension, and then add 79.7g of sodium aluminate solution at a stirring speed of 8500rpm to obtain a mixed solution;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com