Roller shutter type recycle-ratio-adjustable oxidation ditch device and operation method thereof

A circulation ratio and oxidation ditch technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sewage multi-stage treatment, etc., can solve the problem of unadjustable circulation ratio, fixed flow area, and difficult nitrogen removal Phosphorus and other problems, to achieve the effect of saving oxygen consumption, saving construction costs, high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

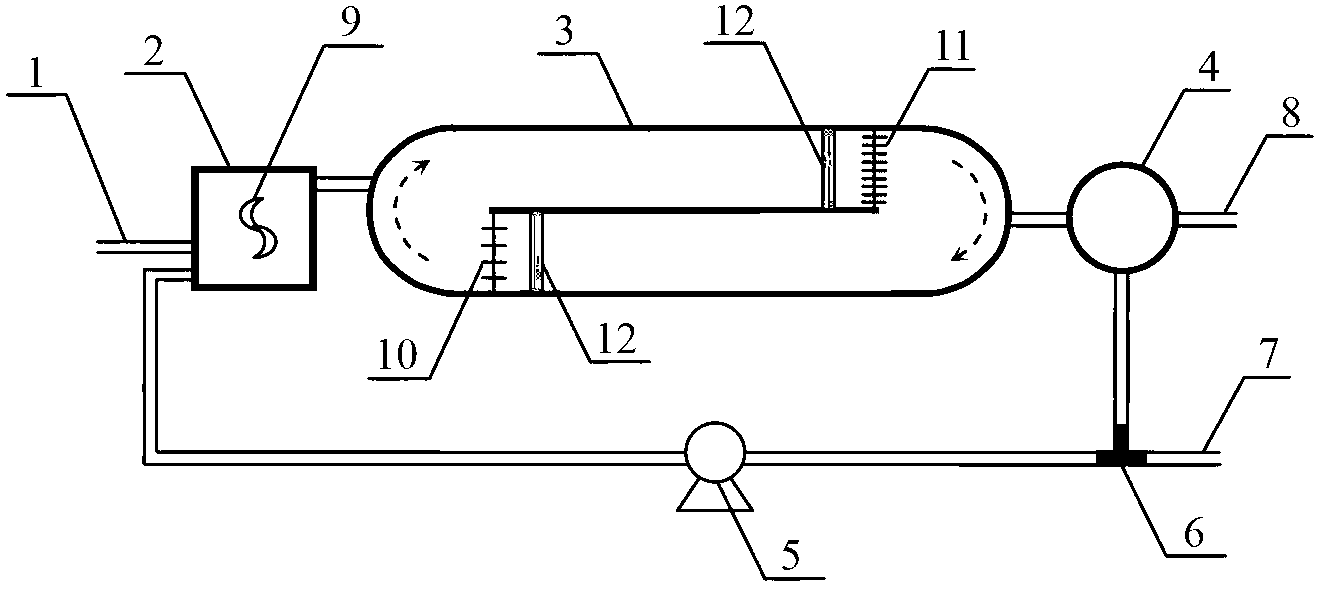

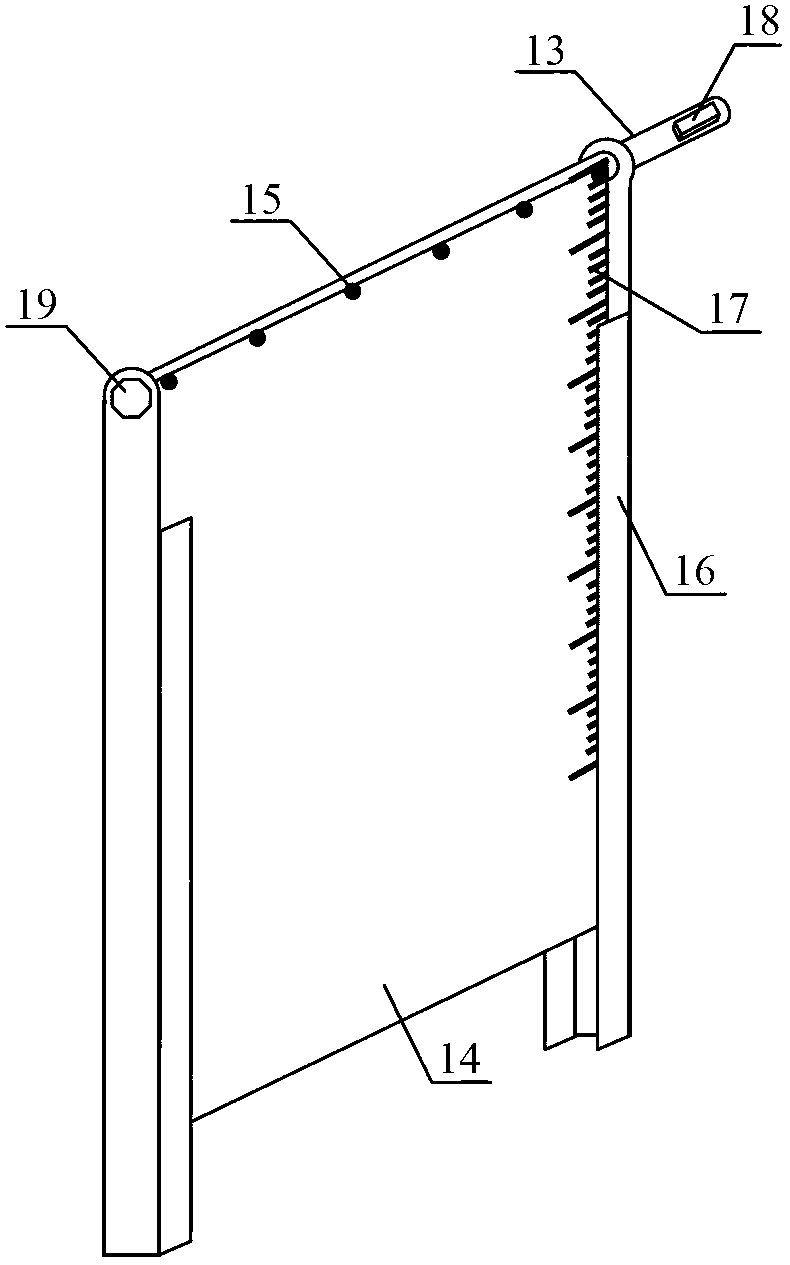

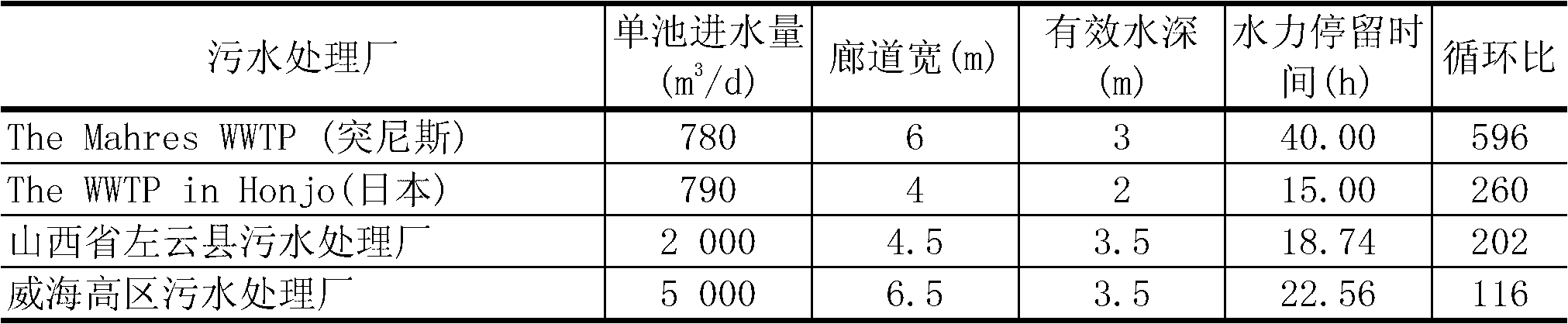

Method used

Image

Examples

Embodiment 1

[0039] Water inflow 50L / h, hydraulic retention time HRT=12h, sludge reflux ratio RS=100%, sludge age SRT=12d, mixed liquor sludge concentration MLSS=4000mg / L, water quality and removal The effect is shown in Table 2.

[0040] Table 2 The decontamination effect of different opening degrees of the oxidation ditch device with adjustable circulation ratio of rolling gate

[0041]

Embodiment 2

[0043] Water intake 50L / h, hydraulic retention time HRT=12h, sludge return ratio R S =100%, sludge age SRT=12d, mixed liquor sludge concentration MLSS=4000mg / L, see Table 3 for the water quality and removal effect of the influent water of the device and the effluent water of the sedimentation tank.

[0044] Table 3 The decontamination effect of different opening degrees of the oxidation ditch device with adjustable circulation ratio of rolling gate

[0045]

Embodiment 3

[0047] Water intake 60L / h, hydraulic retention time HRT=10h, sludge return ratio R S =100%, sludge age SRT=12d, mixed liquid sludge concentration MLSS=4000mg / L, see Table 4 for the water quality and removal effect of the influent water of the device and the effluent water of the sedimentation tank.

[0048] Table 4 The decontamination effect of different opening degrees of the oxidation ditch device with adjustable cycle ratio of rolling gate

[0049]

[0050] In the test stage, the shutter is completely closed, and the mud-water mixture only passes through the bottom channel of the shutter. At this time, the minimum opening degree γ is 0.03. When the shutter is fully opened, the maximum opening degree γ is 1; Within the optimal adjustment range of 0.2≤γ≤0.6, the effluent water quality of the sedimentation tank can reach the first-class B standard in the "Pollutant Discharge Standard for Urban Sewage Treatment Plants (GB18918-2002)". At this time, the effluent from the sed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com