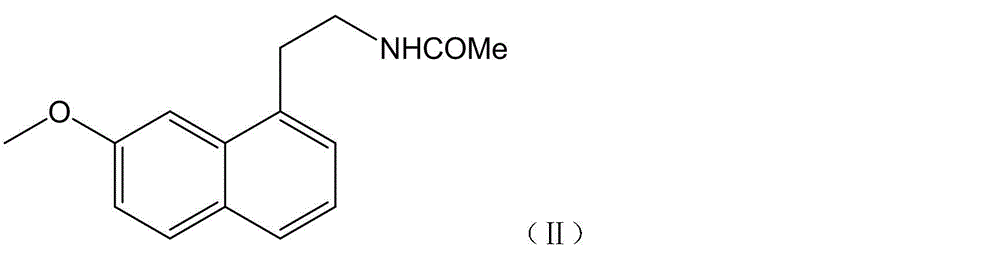

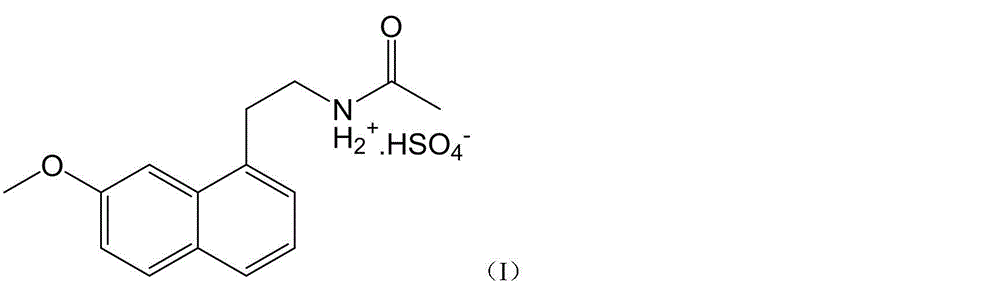

Agomelatine sulfate and preparation method thereof

A technology of agomelatine and sulfate, applied in the field of agomelatine sulfate and preparation thereof, can solve the problems of lack of purity and high agomelatine sulfate, and achieve good fluidity , Improve the purity, good crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 2 grams of agomelatine crude product with a purity of 95.8%, stir and dissolve it with 20 ml of anhydrous ethyl acetate, and slowly add 0.5 ml of concentrated sulfuric acid dropwise in a water bath at room temperature, and a large amount of white solids will precipitate out. Stir for another hour, filter, wash with a small amount of ethyl acetate, and dry at 60°C to obtain 2.7 g of a white solid with a yield of 96.2%, a purity of >99.5%, and a melting point of 160-163°C.

Embodiment 2

[0036] Take 4 grams of agomelatine crude product with a purity of 95.8%, stir and dissolve it with 40 ml of anhydrous ethyl acetate, slowly add 1 ml of concentrated sulfuric acid dropwise in a water bath at room temperature, and a large amount of white solids will precipitate out. Stir for another hour, filter, wash with a small amount of ethyl acetate, and dry at 60°C to obtain 5.48 g of a white solid with a yield of 97.6%, a purity of >99.5%, and a melting point of 160-163°C.

Embodiment 3

[0038] Take 4 grams of agomelatine crude product with a purity of 99.1%, stir and dissolve it with 40 ml of anhydrous ethyl acetate, slowly add 1 ml of concentrated sulfuric acid dropwise in a water bath at room temperature, and a large amount of white solids will precipitate out. Stir for another hour, filter, wash with a small amount of ethyl acetate, and dry at 60°C to obtain 5.5 g of a white solid with a yield of 98.0%, a purity of >99.6%, and a melting point of 160-163°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com