Preparation method of superparamagnetic composite microballoons used in biomedicine

A technology of superparamagnetic and composite microspheres, which is applied to the magnetism of organic materials/organic magnetic materials, scientific instruments, instruments, etc., which can solve the problems of complex detection process, high detection cost, and great pain for patients, and achieve simple preparation process , wide application prospects, the effect of high magnetic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

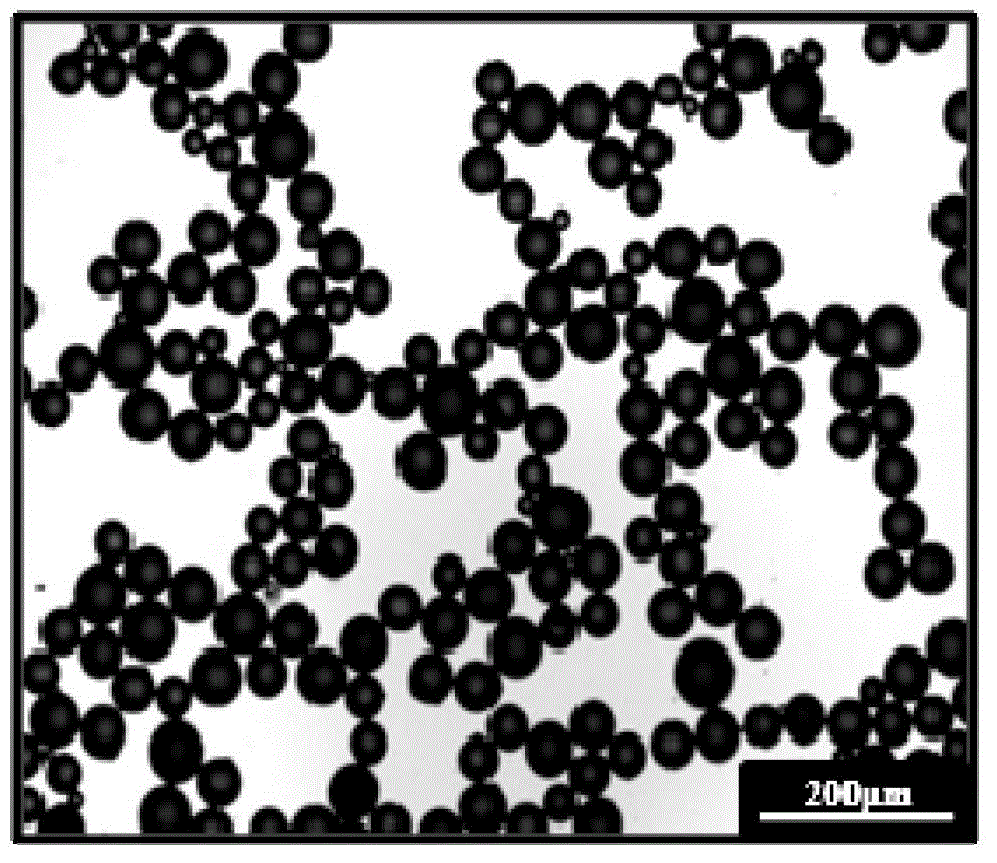

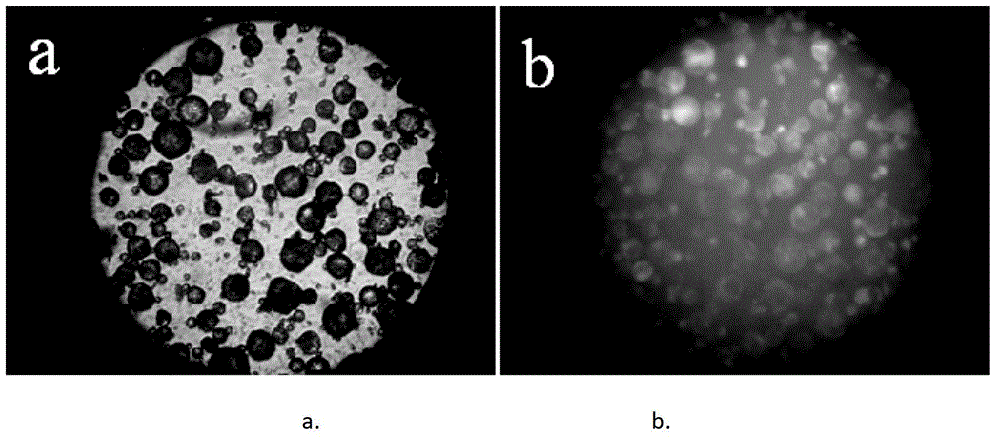

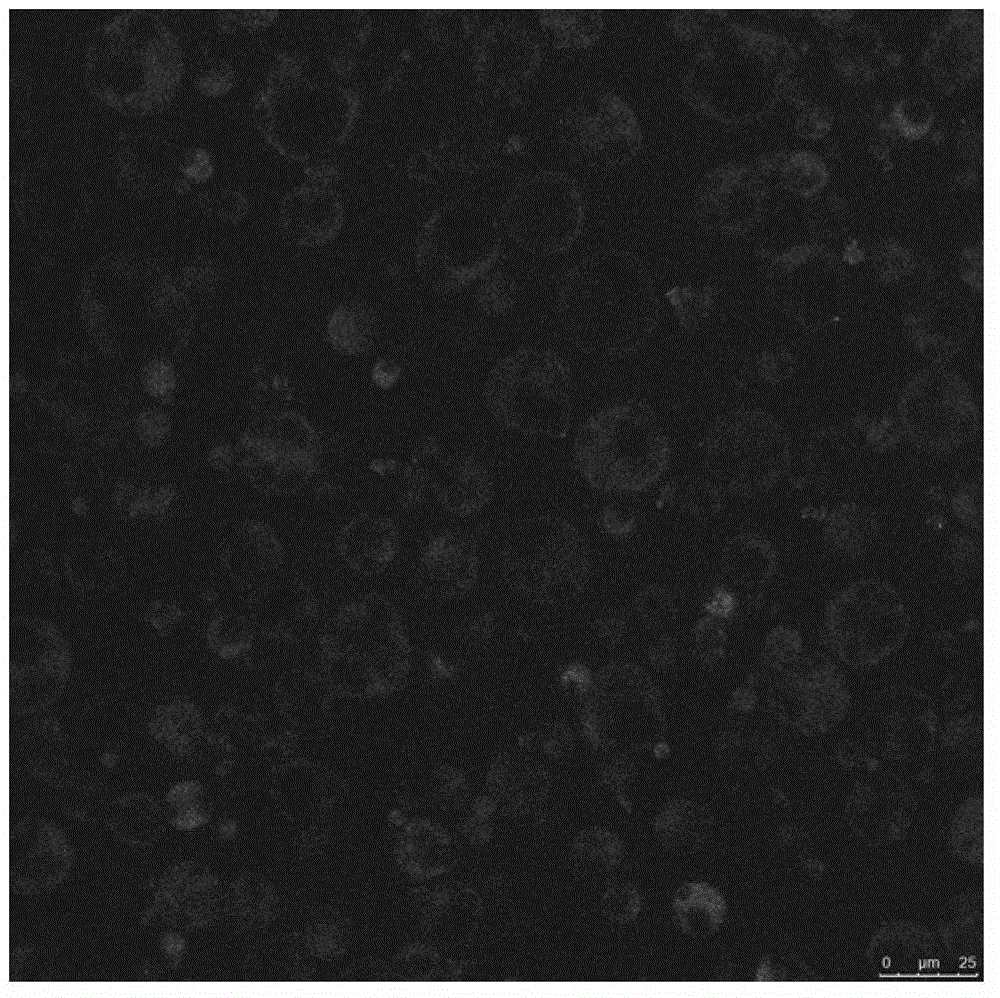

Embodiment 1

[0022] Embodiment one: prepare 100mL standard FeCl respectively by 0.5mol / L 3 ·6H 2 O and FeCl 2 4H 2 O solution, take 63mL Fe 3+ solution and 37mL Fe 2+ The solution was placed in a 250ml four-neck flask. Stir at high speed under the protection of nitrogen, heat the system to 80°C in a water bath, quickly add concentrated ammonia water, and adjust the pH of the system to 10. At this time, the system immediately turns black, and a large amount of black Fe is produced by hydrolysis. 3 o 4 Nanoparticles. After reacting for 1 h, continue to pass nitrogen gas until the system is cooled to room temperature, and wash with deionized water several times until the pH value of the supernatant reaches neutral. Weigh the Fe with a net content of 3g 3 o 4 Disperse nanoparticles into 100mL deionized water, heat up to 80°C under nitrogen protection, add 1.34g oleic acid, react for 40min, cool to room temperature, add 0.67g sodium dodecylbenzenesulfonate, stir for half an hour, and ...

Embodiment 2

[0023] Embodiment 2: The difference between this embodiment and Embodiment 1 is: prepare 100mL standard FeCl at 0.5mol / L respectively 3 ·6H 2 O and FeCl 2 4H 2 O solution, take 60mL Fe 3+ solution and 40mL Fe 2+ The solution was placed in a 250ml four-neck flask. Stir at high speed under the protection of nitrogen, heat the system to 50°C in a water bath, quickly add concentrated ammonia water, and adjust the pH of the system to 9. At this time, the system immediately turns black, and a large amount of black Fe is produced by hydrolysis. 3 o 4 Nanoparticles. After reacting for 1 h, continue to pass nitrogen gas until the system is cooled to room temperature, and wash with deionized water several times until the pH value of the supernatant reaches neutral. Weigh the Fe with a net content of 3g 3 o 4 Disperse nanoparticles in 100mL deionized water, heat up to 60°C under nitrogen protection, add 1.67g oleic acid, react for 30min, cool to room temperature, add 0.5g sodiu...

Embodiment 3

[0024] Embodiment three: the difference between this embodiment and embodiment one is: prepare 100mL standard FeCl respectively by 0.5mol / L 3 ·6H 2 O and FeCl 2 4H 2 O solution, take 66.5mL Fe 3+ solution and 33.5mL Fe2+ The solution was placed in a 250ml four-neck flask. Stir at high speed under the protection of nitrogen, heat the system to 75°C in a water bath, quickly add concentrated ammonia water, and adjust the pH of the system to 11. At this time, the system immediately turns black, and a large amount of black Fe is produced by hydrolysis. 3 o 4 Nanoparticles. After reacting for 60 minutes, continue to pass nitrogen gas until the system is cooled to room temperature, and wash with deionized water several times until the pH value of the supernatant reaches neutral. Weigh the Fe with a net content of 3g 3 o 4 Disperse nanoparticles into 100mL deionized water, heat up to 70°C under nitrogen protection, add 0.67g oleic acid, react for 1h, cool to room temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com