Liquid nitrogen refrigeration micro-wave heating vacuum drier

A vacuum dryer and microwave heating technology, which is applied in the direction of progressive dryers, dryers, and drying solid materials, can solve the problems of uneven heating of products, high equipment maintenance costs, and low heat exchange efficiency, and achieve increased The effect of freezing temperature range, reducing freeze-drying time, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

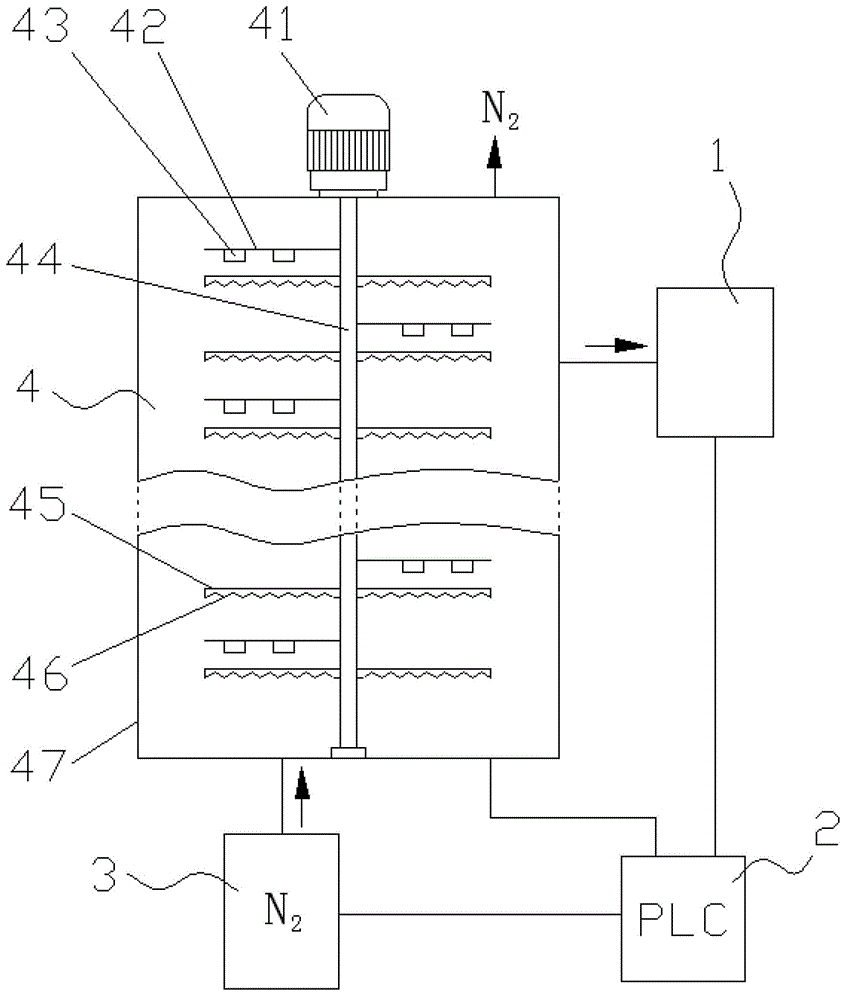

[0020] like figure 1 As shown, a liquid nitrogen refrigerated microwave heating vacuum dryer comprises a freeze-drying part 4 connected with a water circulating vacuum pump 1 and a liquid nitrogen refrigerating system 3, and also includes a freeze-drying part 4 connected with the water circulating vacuum pump 1, the liquid nitrogen refrigerating system 3 and the freeze-drying part 4 PLC main control system 2; freeze-drying part 4 includes a sealed freeze-drying box 47, and a rotating spindle 44 is vertically arranged in the freeze-drying box 47, and the rotating spindle 44 is connected to the multi-layer freeze-drying tray 45 from top to bottom, and each layer is freeze-dried A microwave heating system 42 is arranged above the tray 45, and the microwave heating system 42 includes a microwave generator 43, and two microwave generators 43 are arranged on each layer.

[0021] The bottom of the freeze-drying tray 45 is provided with a concave-convex surface 46, which can reflect t...

Embodiment 2

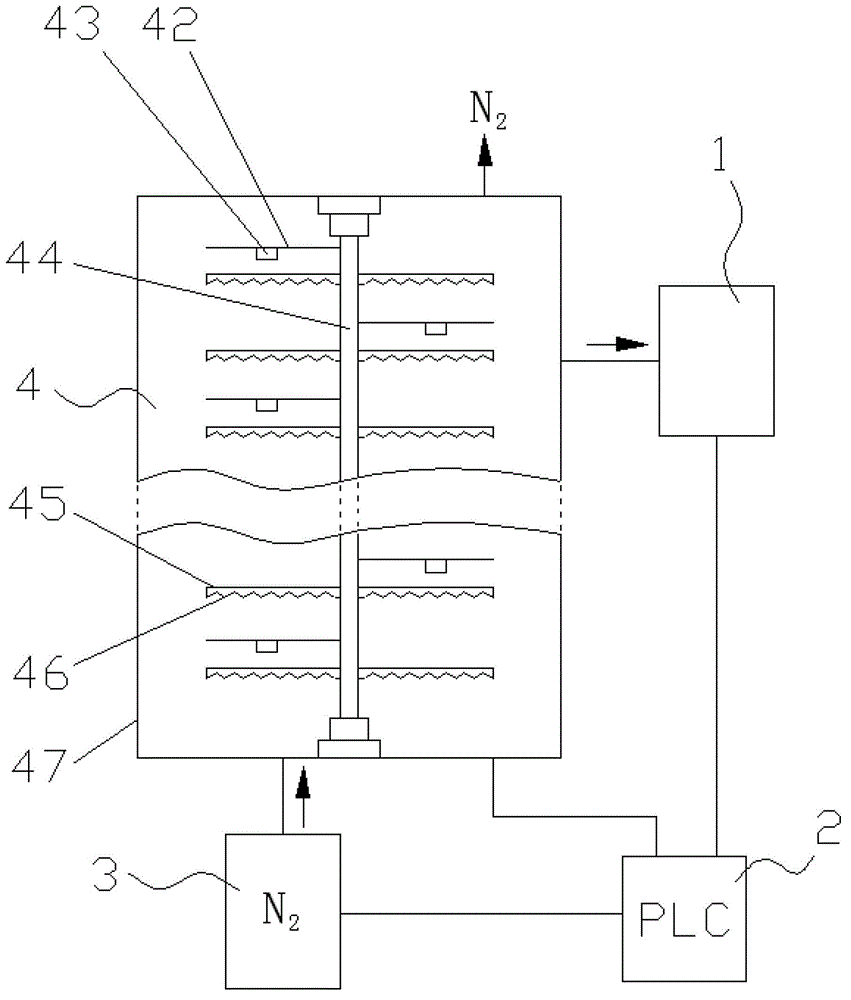

[0023] like figure 2 As shown, a liquid nitrogen refrigerated microwave heating vacuum dryer comprises a freeze-drying part 4 connected with a water circulating vacuum pump 1 and a liquid nitrogen refrigerating system 3, and also includes a freeze-drying part 4 connected with the water circulating vacuum pump 1, the liquid nitrogen refrigerating system 3 and the freeze-drying part 4 PLC main control system 2; freeze-drying part 4 includes a sealed freeze-drying box 47, and a rotating spindle 44 is vertically arranged in the freeze-drying box 47, and the rotating spindle 44 is connected to the multi-layer freeze-drying tray 45 from top to bottom, and each layer is freeze-dried A microwave heating system 42 is provided above the tray 45 , and the microwave heating system 42 includes a microwave generator 43 , one microwave generator 43 is provided on each layer.

[0024] The bottom of the freeze-drying tray 45 is provided with a concave-convex surface 46, which can reflect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com