Continuous lossless whole rock natural gas generation simulation method

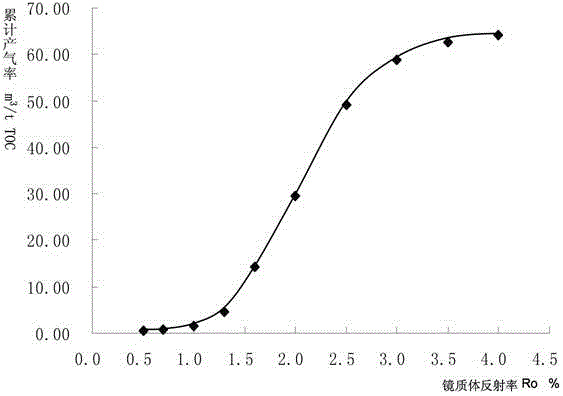

A simulation method and natural gas technology, applied in the field of petroleum geological exploration, can solve the problems of destroying the original structure and composition of source rocks, the experimental results cannot be directly applied, and low efficiency, and achieve the effect of simple operation, high reliability, and fast analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

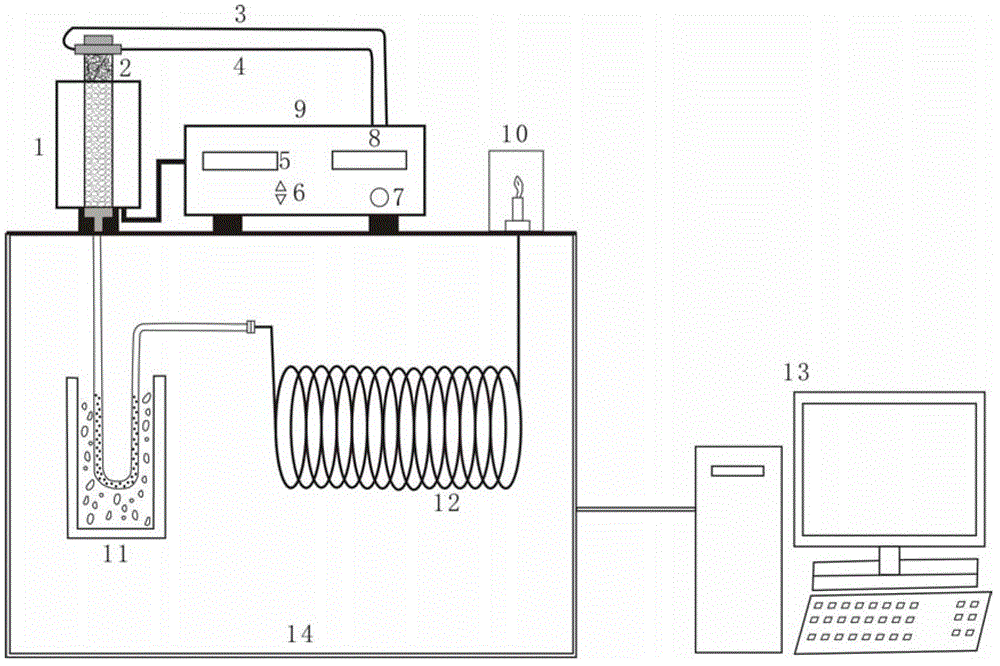

[0034] This embodiment provides a continuous non-loss whole-rock natural gas generation simulation method, which includes the following steps:

[0035] (1) Take 100g of dark gray mudstone core sample from Well Lucan 3 (Toc=4.65%, original Ro=0.5%) in the Liaohe Oilfield Basin, break it into particles with a particle size of 0.85mm-2.0mm, and weigh 2.0g accurately The crushed mudstone sample particles are packed into the sample tube 2 of the thermal cracker, and the two ends of the sample tube 2 are filled with quartz wool;

[0036] (2) the sample tube 2 that the mudstone sample particle is housed, the pyrolysis furnace (heating furnace) 1 of the pyrolyzer are connected on the gas chromatograph 14 inlet and ensure that the interface is airtight;

[0037](3) Regulate the pressure adjustment knob 7 on the thermal cracker controller 9, so that the indication of the carrier gas pressure display gauge 8 remains on 5psi;

[0038] (4) After ventilating in the thermal cracker for 5 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com