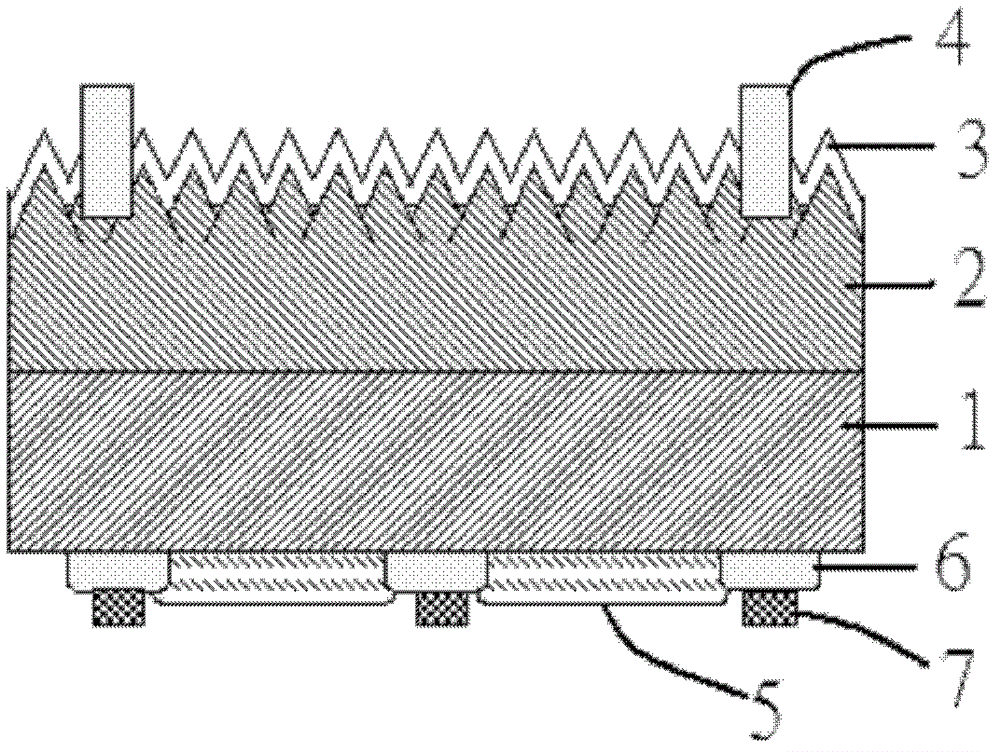

Conductive adhesive composition for solar cell and solar cell assembly thereof

A technology of solar cells and conductive adhesives, applied in conductive materials, electrical components, semiconductor devices and other directions dispersed in non-conductive inorganic materials, can solve the problems of difficult welding, inconvenience, lack of glue, etc., to improve industrial competitiveness, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

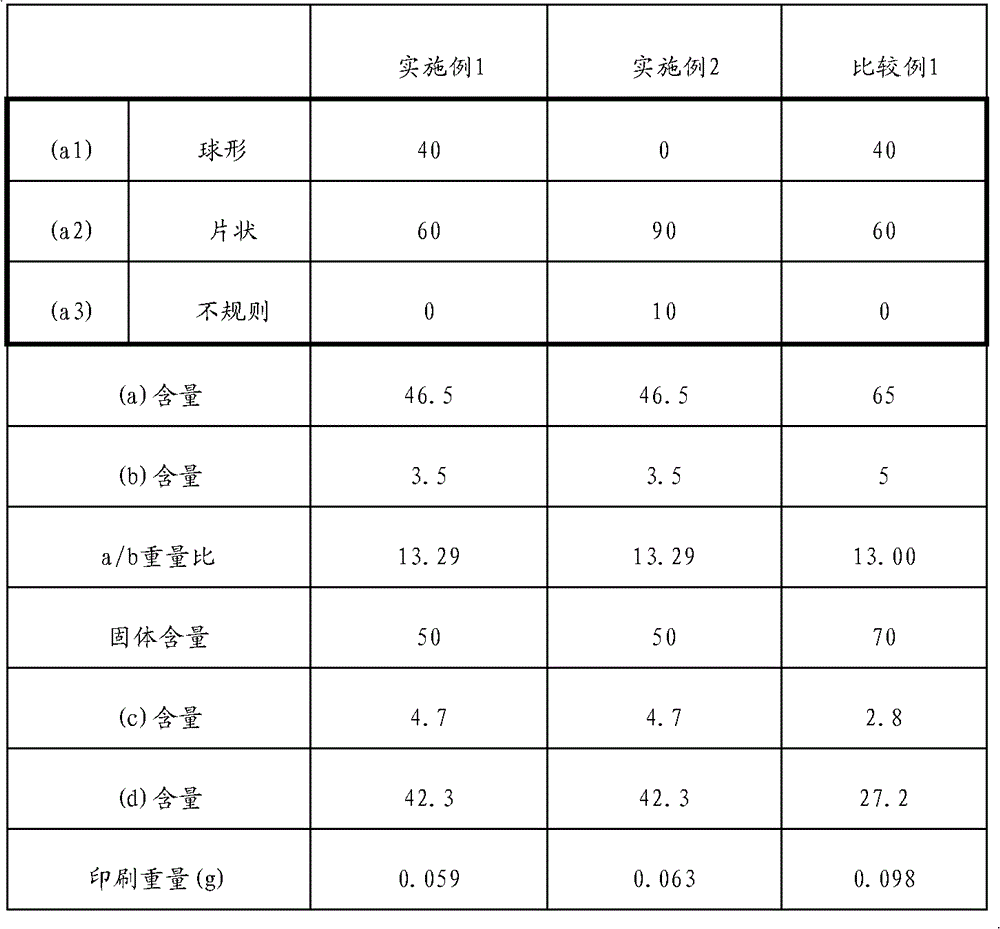

[0047] Manufacture of conductive adhesive composition

[0048] The preparation of the conductive adhesive composition of the present invention includes adding (d) solvent (A: terpineol; B: diethylene glycol monobutyl ether) to silver particles with an average particle diameter (D50) of 0.5-1.3um and glass frit ) and the organic binder, if necessary, add the dispersant (e), the proportion of which is shown in Table 1 and Table 2, and pre-mixed with a mixer.

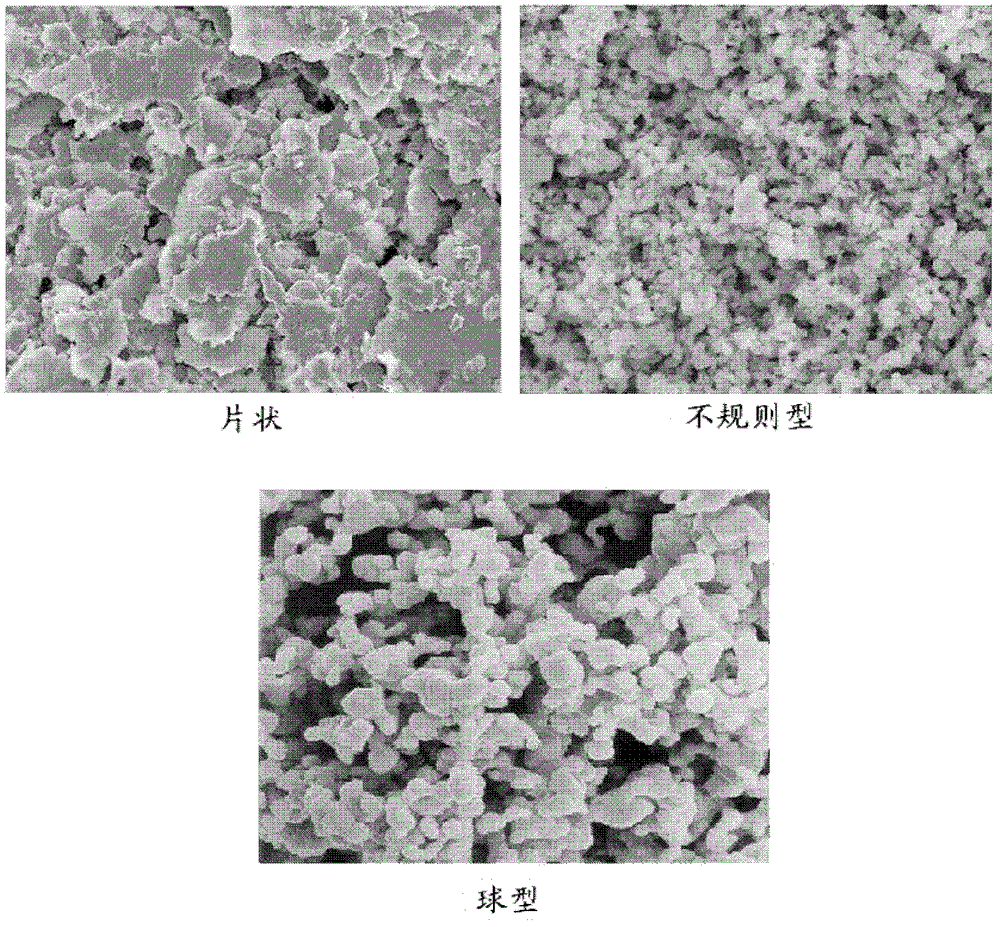

[0049] The appearance and morphology of spherical silver particles (a1), flake silver particles (a2) and irregular silver particles (a3) were analyzed by electron microscope. The analysis results are as follows figure 2 shown.

[0050] (b) The glass frit has Tg=430°C and contains 40wt% bismuth oxide, silicon oxide and boron oxide composition.

[0051] (c) The organic binder is ethyl cellulose resin.

[0052] After mixing, the conductive adhesive composition including silver particles (a), glass frit (b), organic bind...

Embodiment 8

[0069] The main difference between embodiment 8 and embodiments 1-7 is (d) solvent. Wherein the mark A represents terpineol; B represents diethylene glycol monobutyl ether, the change of the conductive adhesive composition (d) the solvent will not affect the power generation efficiency and the pulling force data, and the conductive adhesive composition of the present invention can use any technology The well-known solvents in the world are not limited to the types of solvents mentioned in the present invention, and will not affect the reliability of solar cells.

[0070] In addition, only the weight of (a) silver particles relative to the weight of (b) glass frit differs between Example 4 and Comparative Examples 4-5. It can be seen from Comparative Example 4 that when the weight of (a) silver particles is 10.11 relative to the weight of (b) glass frit, the tensile data performance is slightly lower than that of Example 4, but the welding ability is still judged to be good, bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com