A kind of linkage production method and device of winding rubber hose

A linkage device and hose technology, which is applied to tubular items, other household appliances, household appliances, etc., can solve the problems of screw wear thrust of extruder, uneven thickness of tube wall, insufficient cooling of tube blanks, etc., to improve quality assurance, The effect of improving winding quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

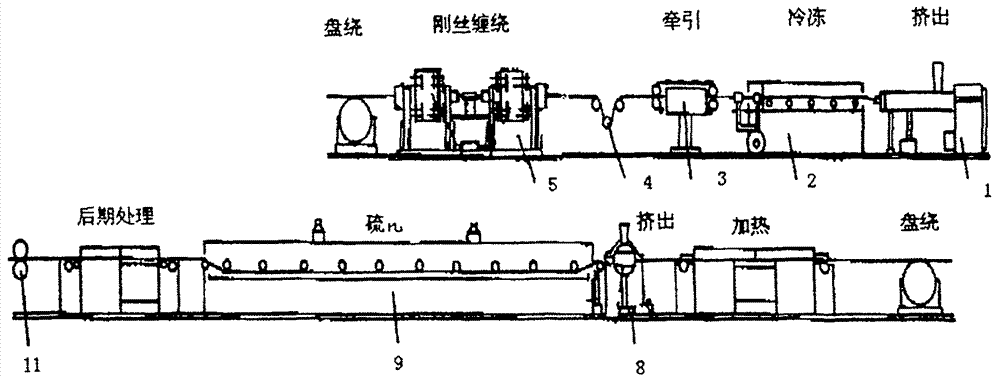

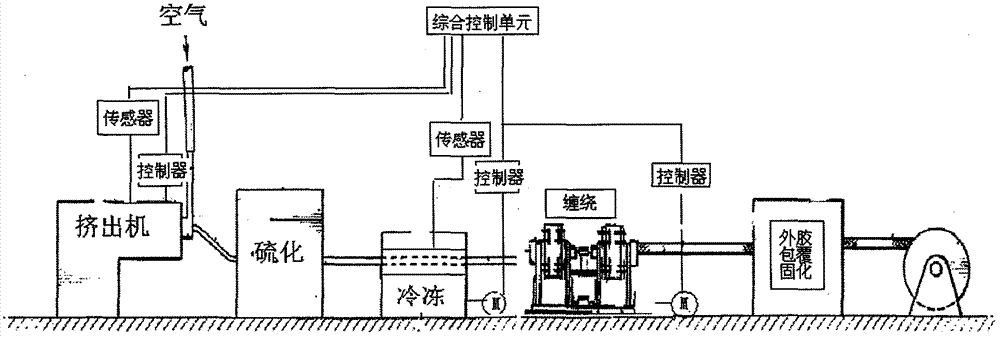

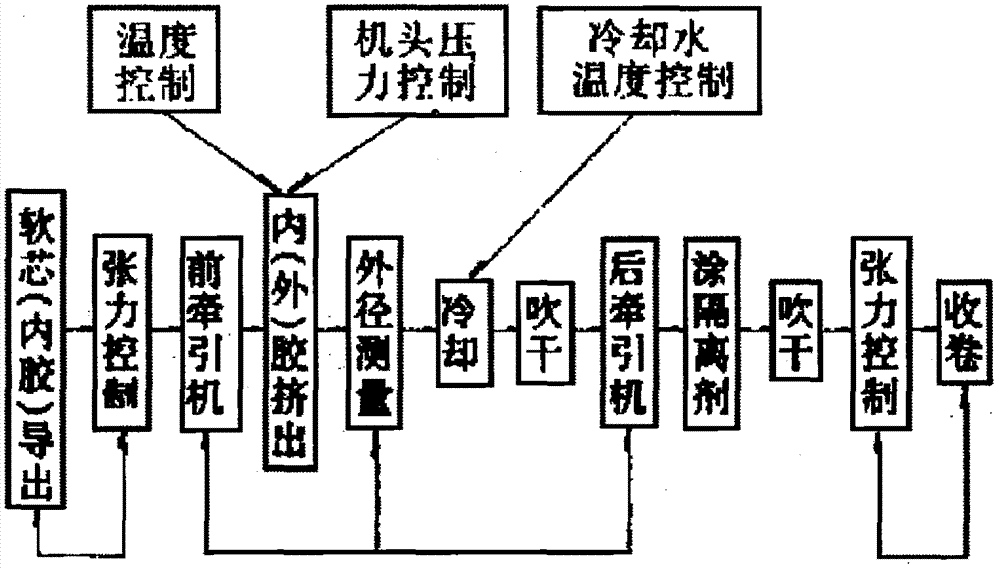

[0300] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Among them, it is an automatic linkage production method and device for high-pressure steel wire wound rubber hose, figure 1 The production linkage line shown is composed of extruders (1 and 8), rubber hose refrigerator (2), haul-off machine (3), steel wire winding machine (5), vulcanization device (9) and its haul-off machine (3), etc. Related control technology and equipment, and designed with an overall traction drive system, and a comprehensive intelligent monitoring system.

[0301] Generally speaking, the overall traction drive system of the steel wire wound rubber hose linkage production line, and the comprehensive intelligent monitoring system, such as figure 2 Shown: Temperature, pressure, infrared or ultrasonic sensors are used, the main control unit is based on single-chip microcomputer or PLC, and the field bus technology is used to set up the upper industrial computer. The design can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com