Composite phosphate removing decolorant and method thereof for removing phosphor and decolouring

A decolorizing agent and waste water technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the rare problems of phosphorus removal and decolorization, achieve safe decolorization, low comprehensive cost, The effect of mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

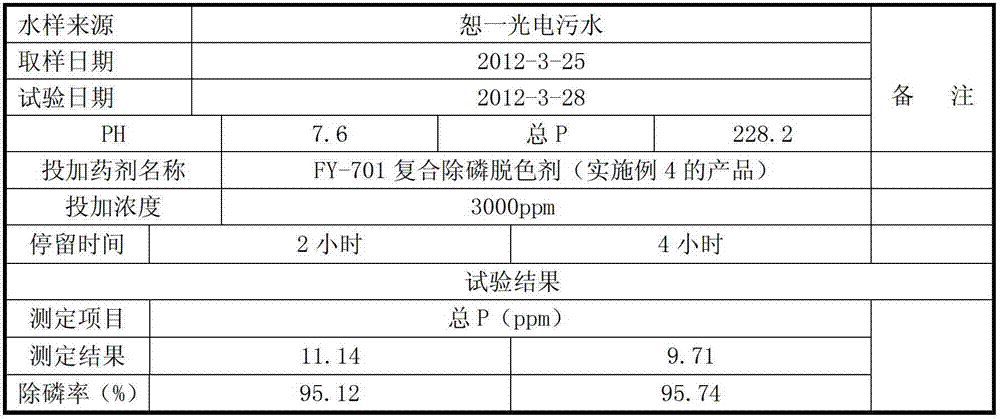

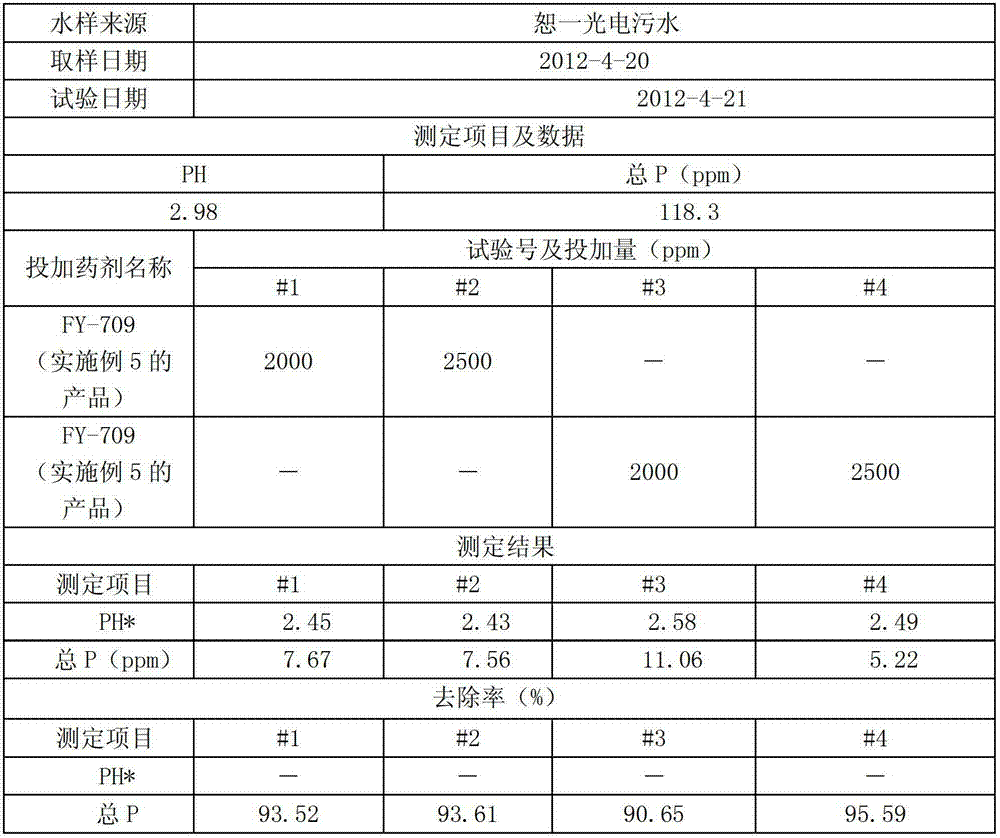

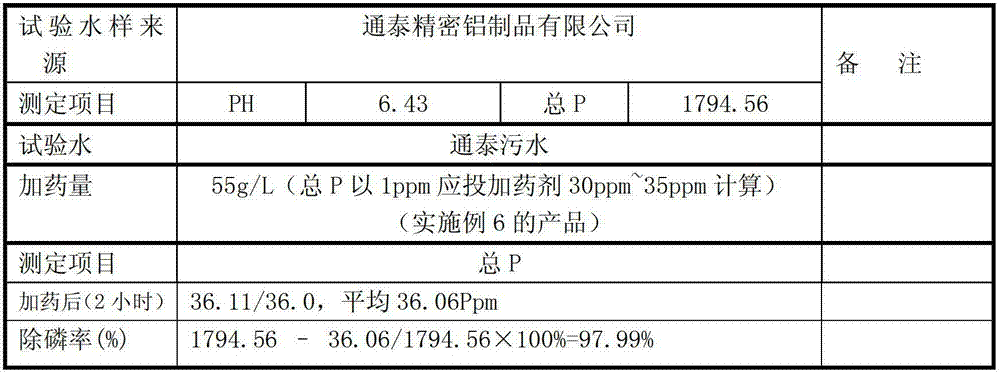

Examples

Embodiment 1

[0014] A kind of compound phosphorus removal decolorizing agent is made of ferrous sulfate, calcium hypochlorite, NaClO 3 、H 2 o 2 , HPAA, borax and purified water are produced by polymerization in proportion, and the mass ratio is 1:0.1:0.05:0.001:0.01:0.001:0.01. Using the decolorization method of the above-mentioned composite phosphorus removal and decolorization agent, the ratio of high-chroma printing and dyeing wastewater to the composite phosphorus removal and decolorization agent (printing and dyeing wastewater / phosphorus removal and decolorization agent) is: 1:0.015, stirred evenly at room temperature, and statically After 20 minutes, the decolorization rate of printing and dyeing wastewater can reach 86.57%.

Embodiment 2

[0016] The operating conditions are the same as in Example 1, except that the composition ratio of the composite phosphorus removal and decolorizing agent is 1:0.15:0.1:0.0015:0.015:0.015:0.015. Use high-chroma printing and dyeing wastewater and the composite phosphorus removal and decoloring agent in proportion (printing and dyeing wastewater / phosphorus removal and decoloring agent) in a ratio of 1:0.02, stir evenly at room temperature, and let it stand for 20 minutes to make the decolorization rate of printing and dyeing wastewater Reached 95.65%.

Embodiment 3

[0018] The operating conditions are the same as in Example 1, except that the composition ratio of the composite dephosphorization and decolorizing agent is 1:0.2:0.5:0.015:0.02:0.02:0.015. Use the high chroma traditional Chinese medicine pharmaceutical wastewater and the compound dephosphorization and decolorizing agent in proportion (organic wastewater of traditional Chinese medicine pharmaceutical / dephosphorization and decolorizing agent): 1:0.025, stir evenly at room temperature, and let it stand for 20 minutes, which can make the traditional Chinese medicine pharmaceutical The decolorization rate of organic wastewater reaches 99.15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com