L-calcium aspartate and its preparation method

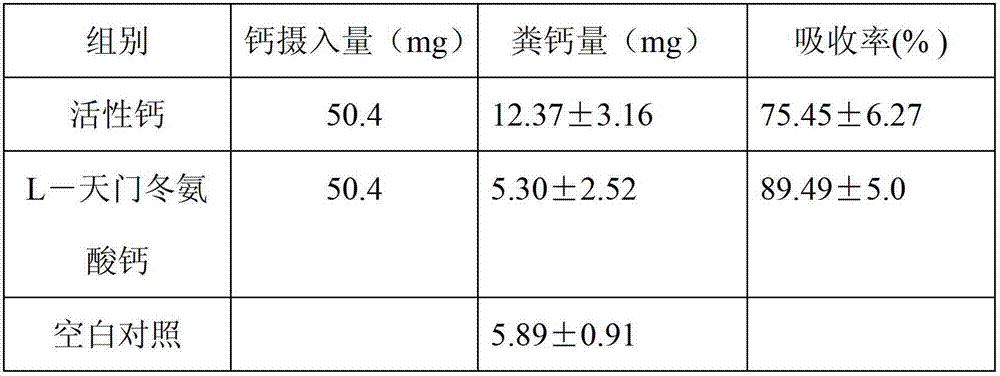

A technology of calcium aspartate and aspartic acid, which is applied in the field of medicine, can solve the problems of cumbersome methods, unfavorable industrial production, and many steps, and achieve the effects of high yield, great application value, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] L-Aspartic Acid 15.7kg

[0024] Calcium carbonate 5.9kg

[0025] Purified water 65.7kg

[0026] Preparation:

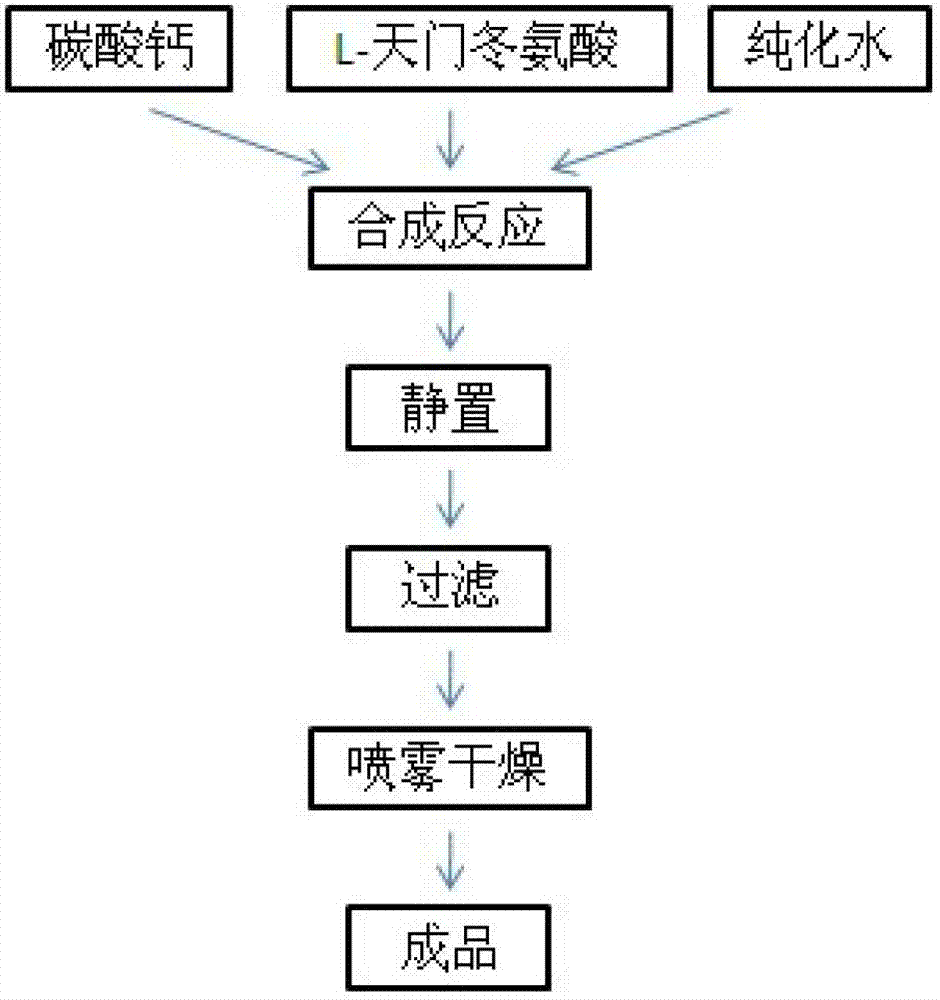

[0027] (1) Add 44.9kg of purified water into the reaction pot, put in L-aspartic acid and calcium carbonate, then add 20.8kg of purified water, heat while stirring, and keep the temperature of the reaction liquid at 75-85°C for 1.5 hours;

[0028] (2) Let the reacted feed liquid stand still for 10 hours (25°C), filter, and take the supernatant;

[0029] (3) The supernatant was spray-dried, and the dry powder was collected to obtain 17.6 kg of calcium L-aspartate, with a yield of 97.50%. Calcium content 12.2%

[0030] (The detection method is based on the Shanghai Enterprise Standard Q / VAGH 5-2007 index: Calcium (calculated as Ca2+), 12±1%)

Embodiment 2

[0032] L-Aspartic Acid 15.7kg

[0033] Calcium carbonate 6.79kg

[0034] Purified water 65.7kg

[0035] Preparation:

[0036] (1) Add 44.9kg of purified water to the reaction pot, add L-aspartic acid and calcium carbonate, then add 20.8kg of purified water, heat while stirring, and keep the temperature of the reaction solution at 75-85°C for 2.5 hours;

[0037] (2) Let the reacted feed liquid stand still for 18 hours (25°C), filter, and take the supernatant;

[0038] (3) The supernatant was spray-dried, and the dry powder was collected to obtain calcium L-aspartate (17.2Kg). The yield is 99.50%. Calcium content 12.6%.

Embodiment 3

[0040] L-Aspartic Acid 15.7kg

[0041] Calcium carbonate 7.67kg

[0042] Purified water 65.7kg

[0043] The preparation method is the same as in Example 1.

[0044] The yield of calcium L-aspartate is 98.50%. Calcium content 12.1%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com