Preparation method of high purity N,N'-dicyclohexylthiourea

A technology of dicyclohexylthiourea and cyclohexylamine, which is applied in the direction of organic chemistry, can solve the problems of easy loss of solvents, cumbersome operation, and inapplicability to industrial production, and achieve the goals of reducing energy consumption, ensuring removal efficiency, and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

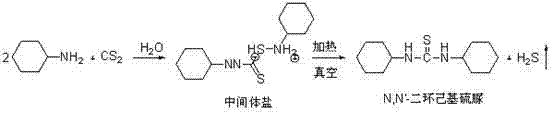

Method used

Image

Examples

Embodiment 1

[0015] Add 500kg of solvent water and 200kg of cyclohexylamine to the reaction kettle, start stirring, raise the temperature to 25°C, start to add 82 kg of carbon disulfide dropwise, control the dropping time for 2h, and control the temperature at 25-30°C; Insulate at -30°C for 1 hour, filter after the reaction is complete, collect the filtered intermediate salt solid and put it back into the reaction kettle, open the vacuum valve, keep the vacuum negative pressure at -0.05MPa, and raise the temperature to 90 o C was dried for 3 hours to remove hydrogen sulfide to obtain 241 kg of N, N'-dicyclohexylthiourea product with a yield of 99.14% and a purity of 99.68%.

[0016] The obtained mother liquor is reused in the following 10 reaction cycles without any treatment, and an average of 241.55 kg of product can be obtained, with a yield of 99.36%.

[0017] Mother liquor cycle times Product weight / kg Product yield / % purity / % 0 241 99.14 99.68 1 241 99.14 ...

Embodiment 2

[0019] Add 500kg of solvent water and 200kg of cyclohexylamine to the reaction kettle, start stirring, cool down to 10°C, start to add 80 kg of carbon disulfide dropwise, control the dropping time for 3 hours, and control the temperature at 10-15°C; Insulate at -15°C for 1h, filter after the reaction is complete, collect the filtered intermediate salt solid and put it back into the reaction kettle, open the vacuum valve, keep the vacuum negative pressure at -0.03MPa, and raise the temperature to 60 o C was dried for 5 hours to remove hydrogen sulfide to obtain 240.3 kg of N, N'-dicyclohexylthiourea product with a yield of 99.08% and a purity of 99.56%.

Embodiment 3

[0021] Add 500kg of solvent water and 160kg of cyclohexylamine to the reaction kettle, start stirring, raise the temperature to 30°C, start to add 68 kg of carbon disulfide dropwise, control the dropping time for 1.5h, and control the temperature at 30-40°C; Insulate at 25-30°C for 2 hours, filter after the reaction is completed, collect the filtered intermediate salt solid and put it back into the reactor, open the vacuum valve, keep the vacuum negative pressure at -0.07MPa, and raise the temperature to 80 o C was dried for 2 hours to remove hydrogen sulfide to obtain 192.3 kg of N,N'-dicyclohexylthiourea product with a yield of 99.08% and a purity of 99.56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com