Rubber composition for tire and tire using the same

A rubber composition and tire technology, applied to special tires, tire parts, tire edges, etc., can solve the problems of increased tire weight, non-disclosure, and deterioration of operational responsiveness, and achieve excellent crack growth resistance and separation resistance Excellent performance and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~22 and comparative example 1~14

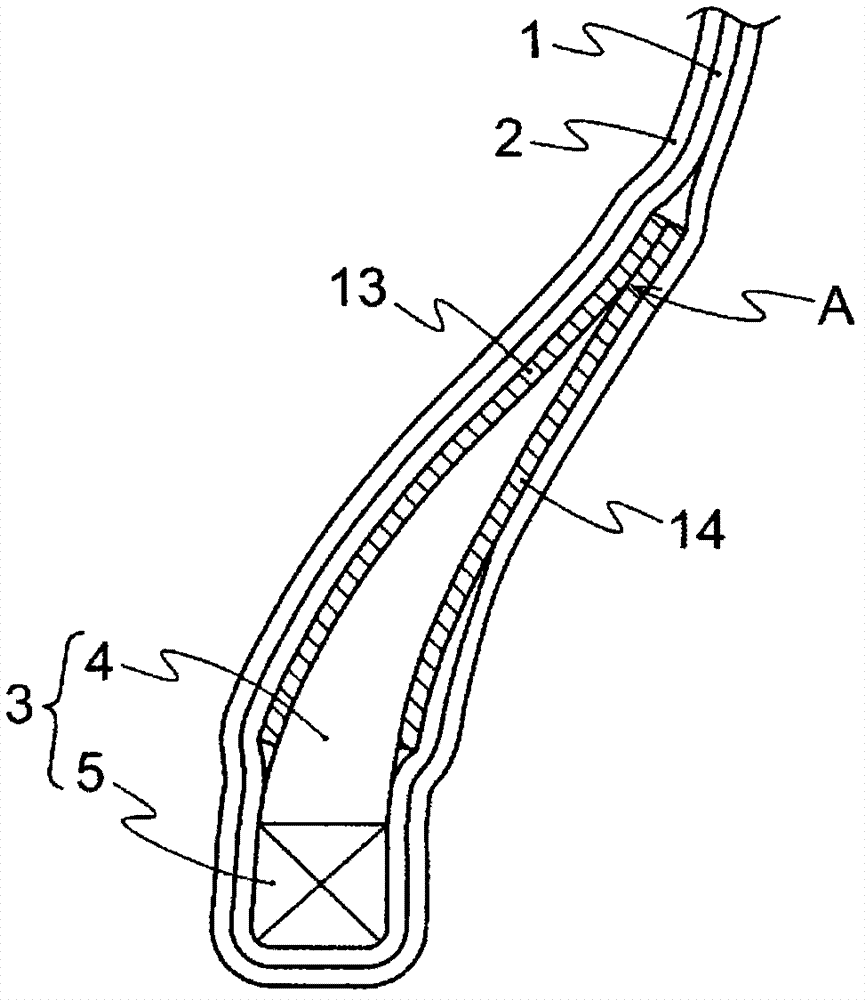

[0170] In the formulation content shown in Table 1 and Table 2, various chemicals except insoluble sulfur and vulcanization accelerator were kneaded with a Banbury mixer. The resulting kneaded product was discharged at 180°C, to which insoluble sulfur and a vulcanization accelerator were added, kneaded in an open roll, and discharged at 105°C, whereby an unvulcanized rubber composition was obtained. Test pieces were prepared by vulcanizing the unvulcanized rubber composition at 170° C. for 12 minutes, and the following tests were performed using the obtained test pieces. Furthermore, the above-mentioned unvulcanized rubber composition was molded with a single rubber extruder into image 3 The shape of the apex strip shown (average thickness: 1.0mm, h1: 60, h2: 15 for the apex strip 13, h1: 60, h2: 15 for the apex strip 14) should be attached to other tire components Combined into an unvulcanized tire, press vulcanized at 150° C. for 35 minutes to manufacture test tires (size:...

Embodiment 23 and 24

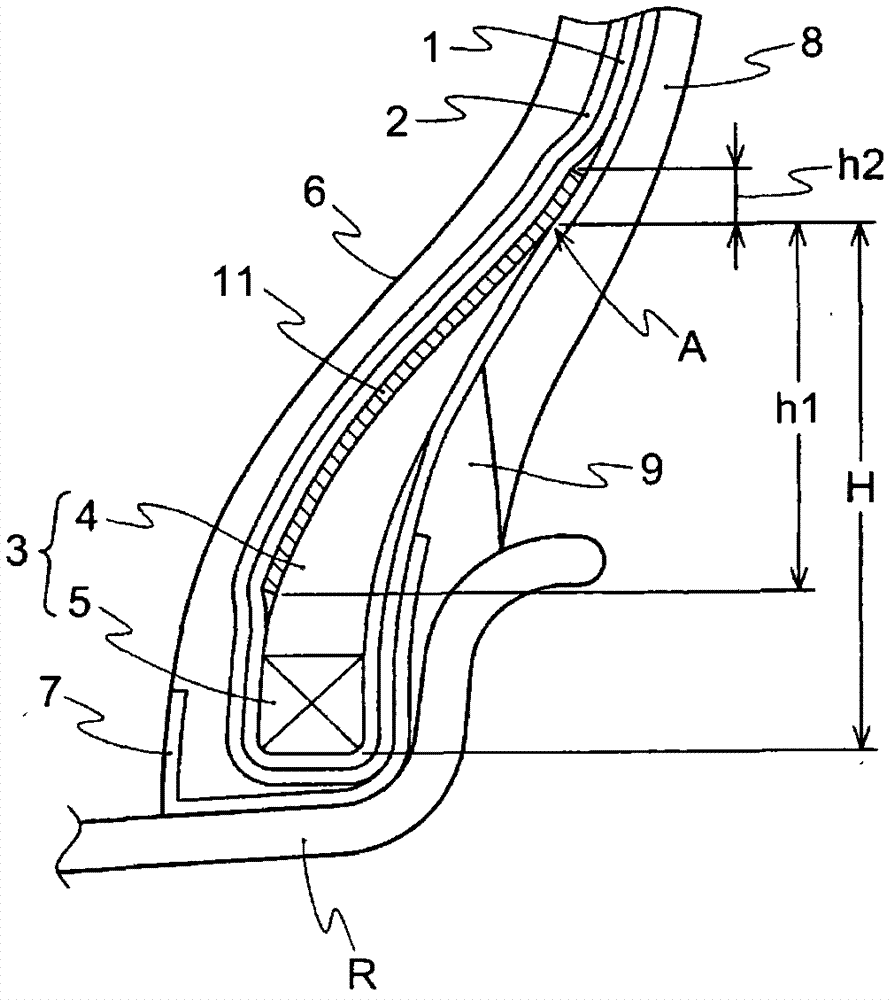

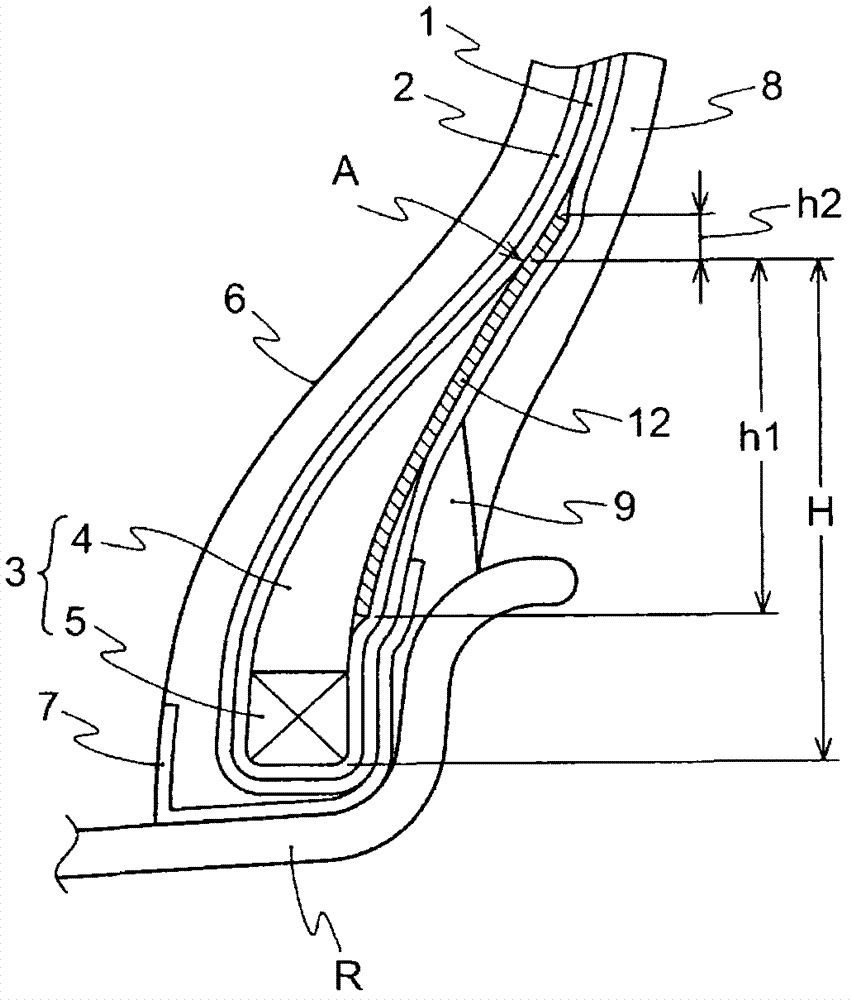

[0172] In order to make the unvulcanized rubber composition Figure 5 (Example 23) and Figure 9 The bead apex of the two-layer structure shown in (Example 24) was produced in the same manner as in the above-mentioned Example 1, except that the unvulcanized rubber composition of the bead apex formulation was molded with a double-two-layer extruder. The test tires were subjected to the tests shown below.

[0173]

[0174] The prepared test piece was cut into width 4mm, length 40mm, and thickness 2mm, and measured the complex modulus of elasticity (E * ) and loss tangent (tanδ) viscoelastic properties. The measurement conditions were: initial strain 10%, dynamic strain 2%, vibration frequency 10 Hz, temperature 70°C. E. * The value of α is 4 to 8 MPa, showing excellent driving stability and separation resistance (strain dispersibility). In addition, the smaller the value of tan δ, the better the low heat build-up property.

[0175]

[0176] According to JIS K6251, a tens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com