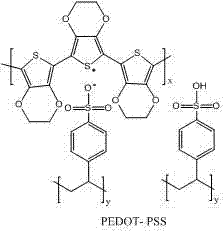

Preparation method for PEDOT-PSS solution with high conductivity

A PEDOT-PSS, high-conductivity technology, applied in the field of preparation of PEDOT-PSS solution, can solve problems such as processing difficulties, and achieve the effects of simple preparation method, good transparency and good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 PEDOT-PSS solution and its preparation

[0025] At room temperature, in a 1000 ml reaction flask, weigh 710 g of deionized water, 1 g of pentosan sulfate sodium and 10 g of PSS, and stir for 10 minutes to form a clear solution; then weigh 8 g of 3,4-ethylenedioxythiophene ( EDOT) was added to the above clear solution, stirred and reacted for 20 minutes, the reaction system became a milky white dispersion; 0.045g of Fe was weighed respectively 2 (SO 4 ) 3 and 19.27g (NH 4 ) 2 S 2 O 8 Add to the above milky white dispersion, stir and react for 20 hours to form a dark blue solution; then weigh 15.1 g of ethylene glycol and add it to the above dark blue solution, stir and react for 20 hours, and finally purify with an ion resin to obtain the target solution.

Embodiment 2

[0026] Example 2 PEDOT-PSS solution and its preparation

[0027] At room temperature, in a 1000 ml reaction flask, weigh 710 g of deionized water, 1 g of sodium pentosan sulfate and 15 g of PSS, and stir for 10 minutes to form a clear solution; then weigh 8 g of 3,4-ethylenedioxythiophene ( EDOT) was added to the above clear solution, stirred and reacted for 30 minutes, the reaction system became a milky white dispersion; 0.045g of Fe was weighed respectively 2 (SO 4 ) 3 and 19.27g (NH 4 ) 2 S 2 O 8 Add to the above milky white dispersion, stir and react for 25 hours to form a dark blue solution; then weigh 15.1 g of ethylene glycol and add it to the above dark blue solution, stir and react for 20 hours, and finally purify with an ion resin to obtain the target solution.

Embodiment 3

[0028] Example 3 PEDOT-PSS solution and its preparation

[0029] At room temperature, in a 1000 ml reaction flask, weigh 700 g of deionized water, 1 g of sodium pentosan sulfate and 25 g of PSS, and stir for 10 minutes to form a clear solution. Weigh 8g of 3,4-ethylenedioxythiophene (EDOT) and add it to the above clear solution, stir and react for 50 minutes, the reaction system becomes a milky white dispersion; then weigh 0.045g of Fe 2 (SO 4 ) 3 and 19.27g (NH 4 ) 2 S 2 O 8 Add to the above milky white dispersion, stir and react for 20 hours to form a dark blue solution; then weigh 30 g of ethylene glycol and add it to the above dark blue solution, stir and react for 20 hours, and finally purify with an ion resin to obtain the target solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com