Preparation method for 3119 light fast red BBS

A technology of sunfast red and B acid, applied in the direction of organic dyes, etc., can solve the problems of artificial waste, high energy consumption, poor dispersibility, etc., and achieve the effect of avoiding high energy consumption, avoiding artificial waste and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

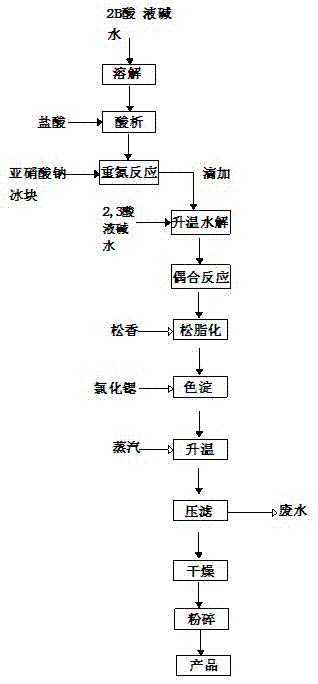

[0020] figure 1 A preparation method of 3119 Fast Red BBS is shown, the method includes the following steps: dissolve 2B acid and liquid caustic soda in a dissolving kettle until transparent, add ice and cool down to the process temperature (0°C-5°C); add Perform acid analysis with hydrochloric acid until PH = 0.5-1; add sodium nitrite solution and ice cubes, stir for 1 hour, and reserve for later use; add 2,3 acid in the dissolution kettle, then add liquid caustic soda and water to raise the temperature to 60°C, dissolve it until transparent and put it into the coupling kettle, adjust the coupling temperature to 10°C, and the coupling volume is 20 times that of the coupling components, then add the diazonium liquid solution reserved for use for coupling, after the coupling is completed, stir for 30 minutes, then adjust the pH value to 9.5; add dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com