Boric acid decontamination soap

A boric acid and decontamination technology, which is applied in the field of complex soap, can solve the problems of fabrics that are difficult to rinse, have poor hard water resistance, and affect detergency, and achieve the effect of improving hard water resistance, excellent hard water resistance, and excellent hard water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

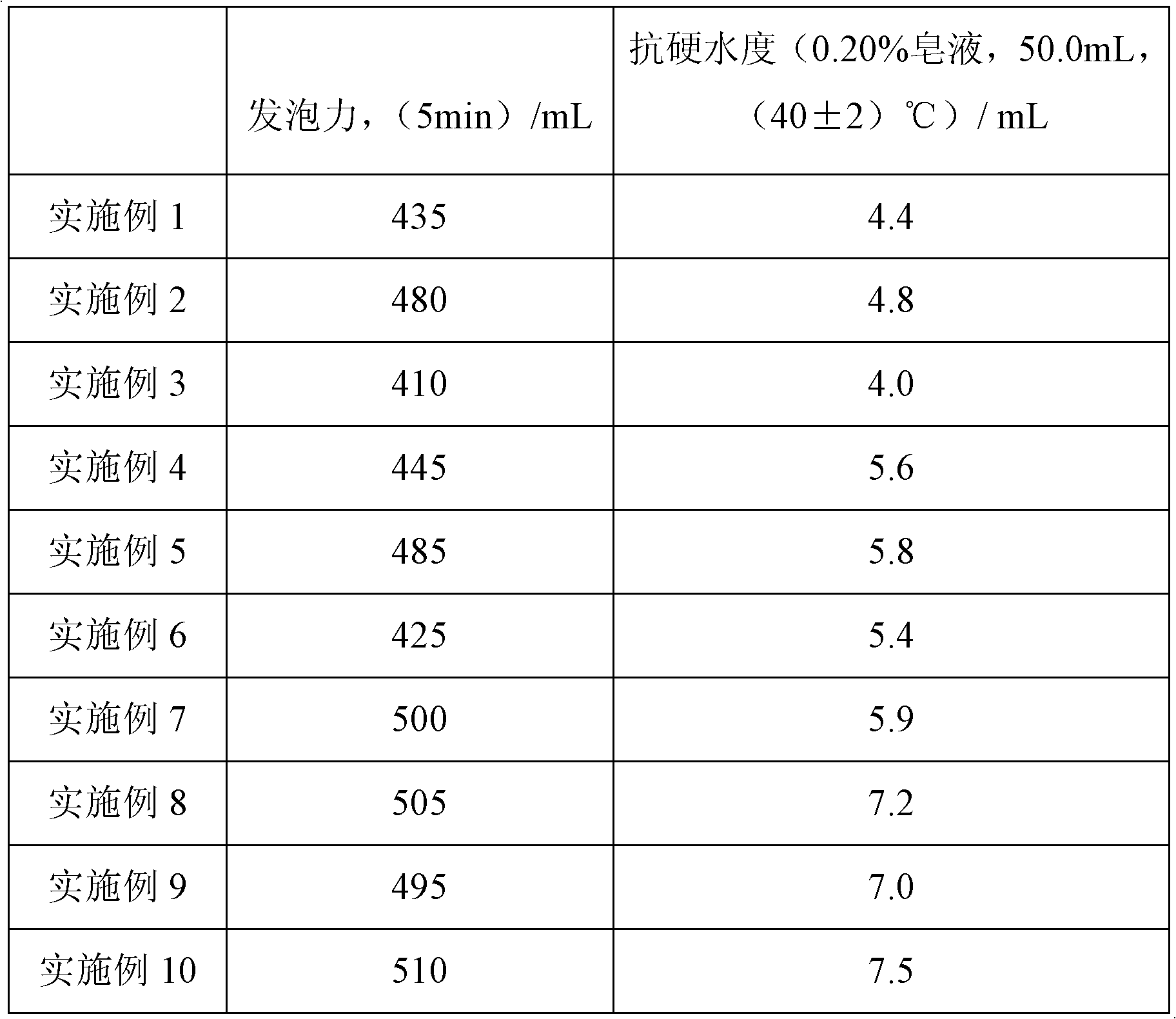

Examples

Embodiment 1

[0066] Take each raw material by weighing corresponding embodiment 1 in table 1.

[0067] Under normal temperature and pressure, add each raw material into the kneader, stir, pulverize and mix evenly, transport the mixture to the grinder to grind evenly, and then send the material to the vacuum layering machine for layering, and after cutting, the washing powder of the present invention can be obtained. Disinfect soap.

[0068] Described fatty alcohol polyoxyethylene ether, chemical formula is RO-(CH 2 CH 2 O) n -H, where R=C14, n=12.

[0069] Table 1: Formula table of boric acid decontamination soap Unit: kg

[0070] raw material

[0071] In Table 1, the grease formula of the soap grains is: 85wt% tallow and mutton oil and 15wt% coconut oil, and the fatty acid content in the soap grains is 69%.

Embodiment 2

[0073] Take each raw material by weighing corresponding embodiment 2 in table 1.

[0074] Prepare boric acid decontamination soap according to the method described in Example 1.

[0075] Described fatty alcohol polyoxyethylene ether, chemical formula is RO-(CH 2 CH 2 O) n -H, where R=C12, n=6.

Embodiment 3

[0077] Take each raw material by corresponding embodiment 3 in table 1.

[0078] Prepare boric acid decontamination soap according to the method described in Example 1.

[0079] Described fatty alcohol polyoxyethylene ether, chemical formula is RO-(CH 2 CH 2 O) n -H, where R=C18, n=18.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com