Composite process of reflecting lens assembly of disc-type solar spotlight tracking system

A technology of solar concentrating and tracking system, applied in the field of reflective lens components of dish-type solar concentrating tracking system, can solve the problems of specifications, number of pieces, many fixing screws, affecting the reflectivity of visible light, poor precision of hyperboloid, etc. The effect of light weight, small footprint and low number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: The composite process of the reflective mirror assembly of the dish solar concentrating tracking system of the present invention includes the following steps:

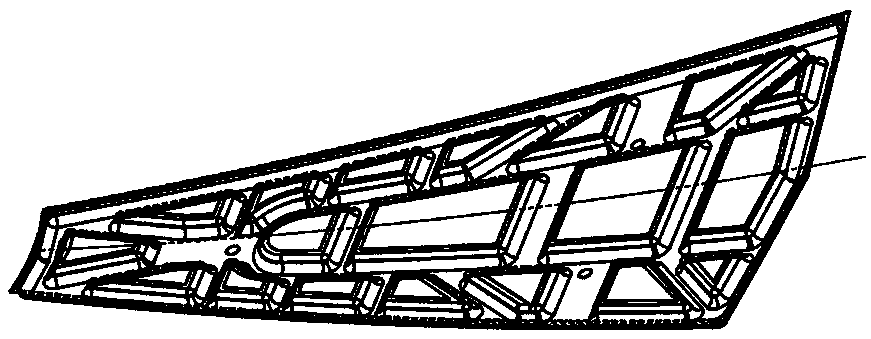

[0043] 1. Hyperbolic fan-shaped metal backplane: the height of the hyperbolic fan-shaped metal backplane is 1500mm, the bottom width of the hyperbolic fan-shaped metal backplane is 700mm, and the bottom width of the hyperbolic fan-shaped metal backplane is 1200mm;

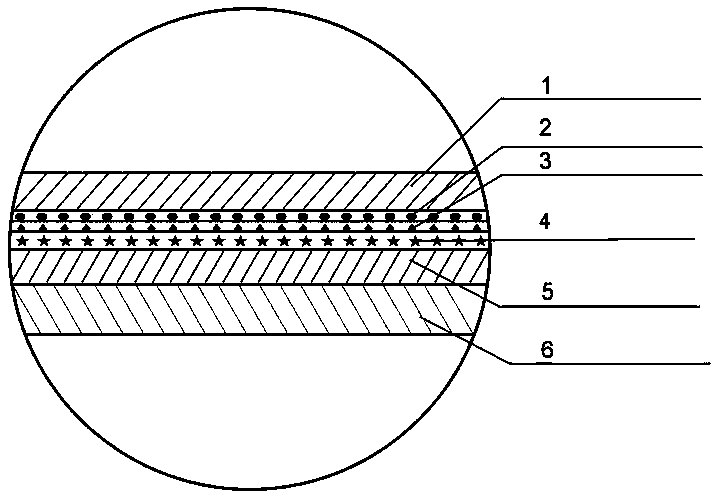

[0044] (1) Stretch the cold-rolled steel plate with 0.8 mm, and stretch it with a mold to form a fan-shaped bottom plate 6 with a hyperbolic surface with reinforcing ribs;

[0045] (2) Stretch the cold-rolled steel plate with 0.8 mm, and stretch it into a fan-shaped panel 5 with a hyperboloid with a mold.

[0046] (3) The hyperbolic fan-shaped base plate 6 with reinforcing ribs and the hyperbolic fan-shaped panel 5 are integrated by welding to form a hyperbolic fan-shaped metal back plate;

[0047] (4) Dip-coat cathodic electroph...

Embodiment 2

[0058] Embodiment 2: The composite process of the reflective mirror assembly of the dish solar concentrating tracking system of the present invention includes the following steps:

[0059] 1. Hyperbolic fan-shaped metal backplane: the height of the hyperbolic fan-shaped metal backplane is 1700mm, the bottom width of the hyperbolic fan-shaped metal backplane is 400mm, and the bottom width of the hyperbolic fan-shaped metal backplane is 1000mm;

[0060] (1) Stretch the cold-rolled steel plate with 0.8mm, and stretch it with a mold to form a fan-shaped bottom plate with a double-curved surface with reinforcing ribs;

[0061] (2) Stretch the cold-rolled steel plate with 1.0 mm, and stretch it into a fan-shaped panel with a hyperboloid with a mold.

[0062] (3) The hyperbolic fan-shaped bottom plate with stiffeners and the hyperbolic fan-shaped panel are welded together to form a hyperbolic fan-shaped metal backplane;

[0063] (4) Dip-coat cathodic electrophoretic pain...

Embodiment 3

[0074] Embodiment 3: The composite process of the reflective lens assembly of the dish solar concentrating tracking system of the present invention includes the following steps:

[0075] 1. Hyperbolic fan-shaped metal backplane: the height of the hyperbolic fan-shaped metal backplane is 2000mm, the bottom width of the hyperbolic fan-shaped metal backplane is 260mm, and the bottom width of the hyperbolic fan-shaped metal backplane is 800mm;

[0076] (1) Stretch the cold-rolled steel plate with 0.8mm, and stretch it with a mold to form a fan-shaped bottom plate with a double-curved surface with reinforcing ribs;

[0077] (2) Stretch the cold-rolled steel plate with 1.5mm, and stretch it into a fan-shaped panel with a hyperboloid with a mold.

[0078] (3) The hyperbolic fan-shaped bottom plate with stiffeners and the hyperbolic fan-shaped panel are welded together to form a hyperbolic fan-shaped metal backplane;

[0079] (4) Dip-coat cathodic electrophoretic paint anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com