Structure for conducting and cooling high-temperature superconducting magnet

A conduction refrigeration, high temperature superconducting technology, applied in superconducting magnets/coils, refrigerators, magnetic objects, etc., can solve the problems of large temperature gradient and slow cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

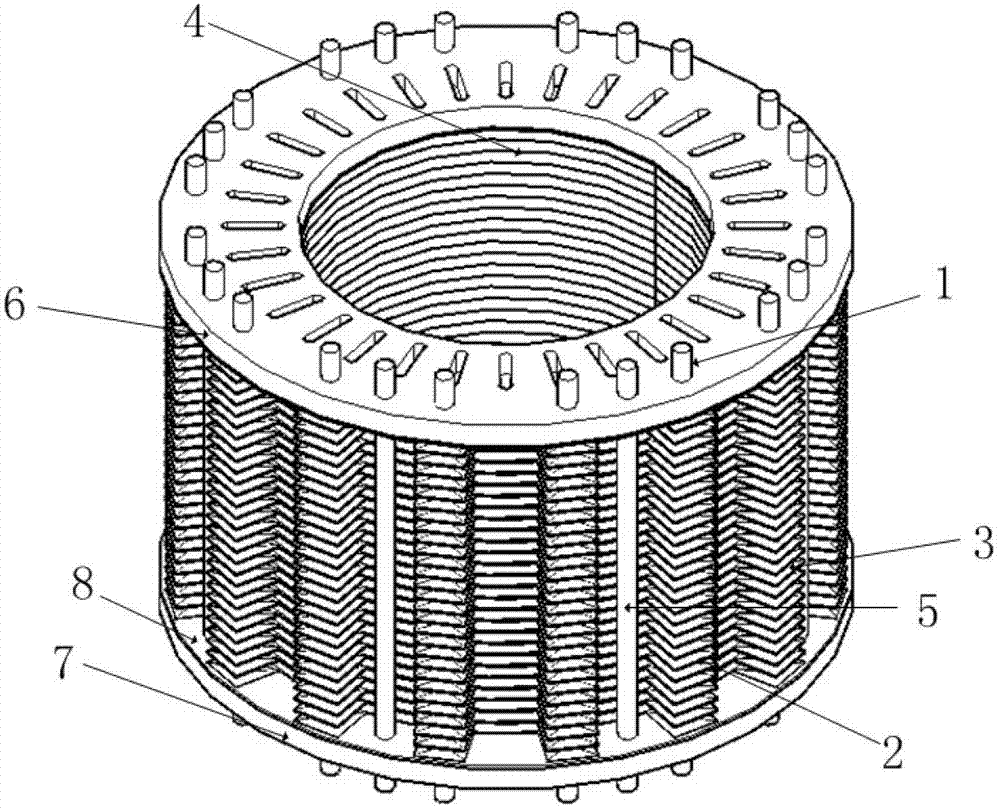

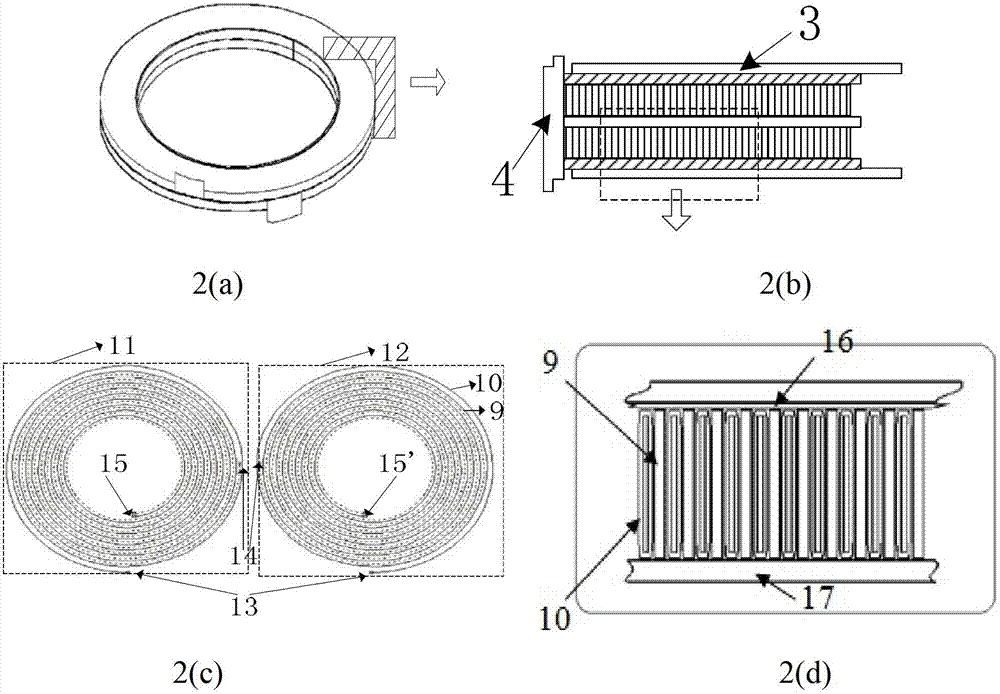

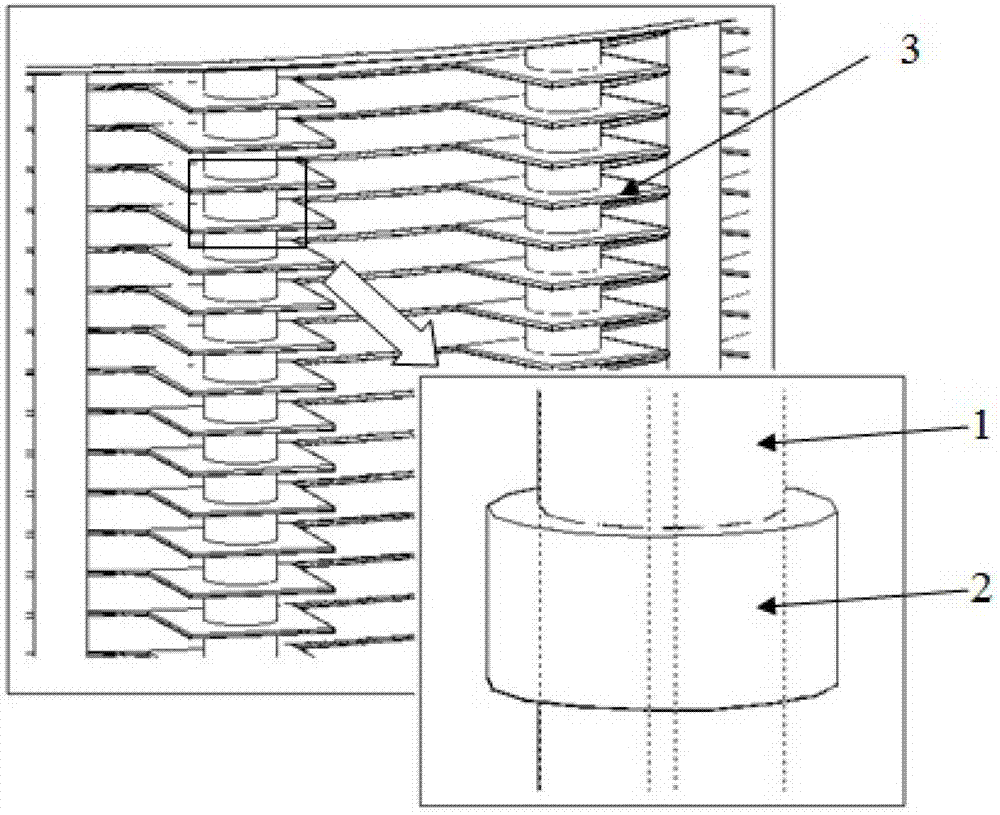

[0034] Taking the conduction cooling scheme of 100kJ / 50kW SMES magnet as an example to introduce the present invention, the design requires that the time required for the high temperature superconducting magnet to cool down from 20°C to 20K should not exceed 8 hours. At 20K, the temperature rise of the magnet during the process from no-load to 100kJ energy storage within 15s does not exceed 5K. When performing 50kW power exchange at 20K, the temperature rise per second does not exceed 2K.

[0035] The main parameters of the 100kJ / 50kW SMES magnet are shown in Table 1

[0036] Table 1 Main parameters of 100kJ / 50kW SMES magnet

[0037] superconducting tape

Bi-2223

20K

Inductance value

11.9H

Maximum working current

129A

magnet structure

single solenoid

number of superconducting biscuits

28

superconducting biscuit inner diameter

340mm

Superconducting double cake oute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com