Method for improving write redundancy of high SRAM (static random access memory)

A write redundant, static random technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

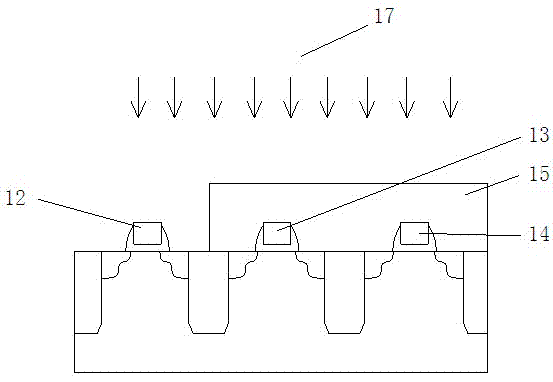

[0022] In the first embodiment of the present invention, please continue to refer to Figure 4a and Figure 4b shown. The above-mentioned lattice structure 18 is specifically a silicon carbide lattice structure. After the carbon implantation 17 process is performed, the source and drain ends of the NMOS device 12 and the source and drain ends of the pull-up tube 14 form a silicon carbide lattice structure.

[0023] In the second embodiment of the present invention, the above-mentioned covering layer 15 is photoresist.

[0024] In the third embodiment of the present invention, after carbon implantation 17 is performed on the NMOS device 12, the PMOS device 13 and the pull-up tube 14, an annealing process is required to finally make the source and drain ends of the NMOS device 12 and the pull-up tube 14 The source-drain two-terminal silicon carbide lattice structure.

[0025] To sum up, using the method of the present invention to improve the writing redundancy of the SRAM, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com