Silicone-free high elasticity coated drug bottle plug and manufacturing method

A manufacturing method and high-elasticity technology, applied in the field of drug bottle stoppers, can solve problems such as poor sealing performance of bottle stoppers on drugs, influence of silicone oil drug compatibility, high manufacturing cost of complex shapes, etc. Compatibility, the effect of avoiding siliconization pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

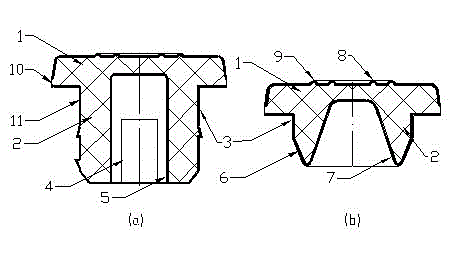

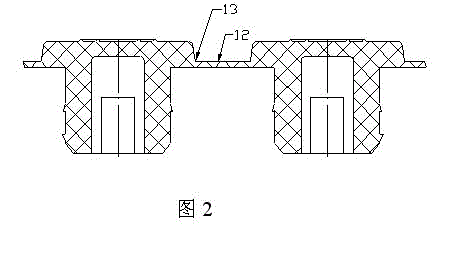

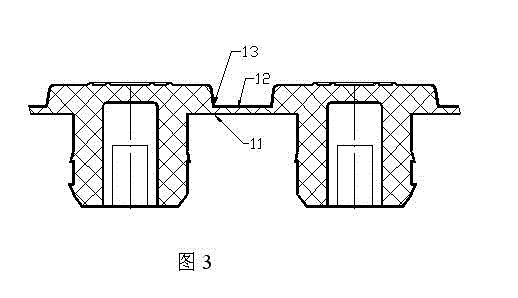

[0039] The present invention as figure 1 , figure 2 , image 3 , as shown, the non-siliconized high-elastic coating drug bottle stopper includes a cork crown and a stopper neck. The inner wall of the plug neck is a cylindrical surface or a tapered cylindrical surface, an acupuncture ring is arranged at the center of the upper surface of the plug crown, and an anti-sticking protrusion is arranged between the peripheral edge of the acupuncture ring and the peripheral edge of the plug crown, An annular elastic mouth is provided at the lower end of the cork crown, and a coating layer is provided covering the cork.

[0040] The height of the annular elastic opening can be set according to the actual needs of the user. In this embodiment, the height of the annular elastic opening is 1mm.

[0041] The material of the coating layer is parylene, and the thickness of the coating layer is 2.5 μm.

[0042] The material used for the bottle stopper is halogenated butyl rubber.

[0043...

Embodiment 2

[0049] The present invention as Figure 4 , Figure 5 , Figure 6 As shown, the structure and manufacturing method of the non-siliconized highly elastic coated drug bottle stopper are basically the same as those in Example 1, except that: 1. In terms of structure, the annular elastic boss is set between the membrane separation edge and the upper surface of the plug crown, and placed on the outer side of the plug crown. The height of the annular elastic opening is the sum of the height of the annular elastic boss and the thickness of the membrane separation edge , the height of the annular elastic boss is 2mm, and the thickness of the membrane side is 0.9mm. 2. In the manufacturing method, an annular groove matching the position and height of the annular elastic boss is provided on the side of the crown cavity of the bottle stopper mold, and the annular elastic boss is formed after the rubber stopper is vulcanized. a

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com