Ultrasonic vibration aided stir friction welding process and device

An ultrasonic vibration and auxiliary stirring technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of hindering the ultrasonic vibration of stirring needles, complicated system fabrication, and large equipment changes, so as to improve welding quality and expand the scope of application. , the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

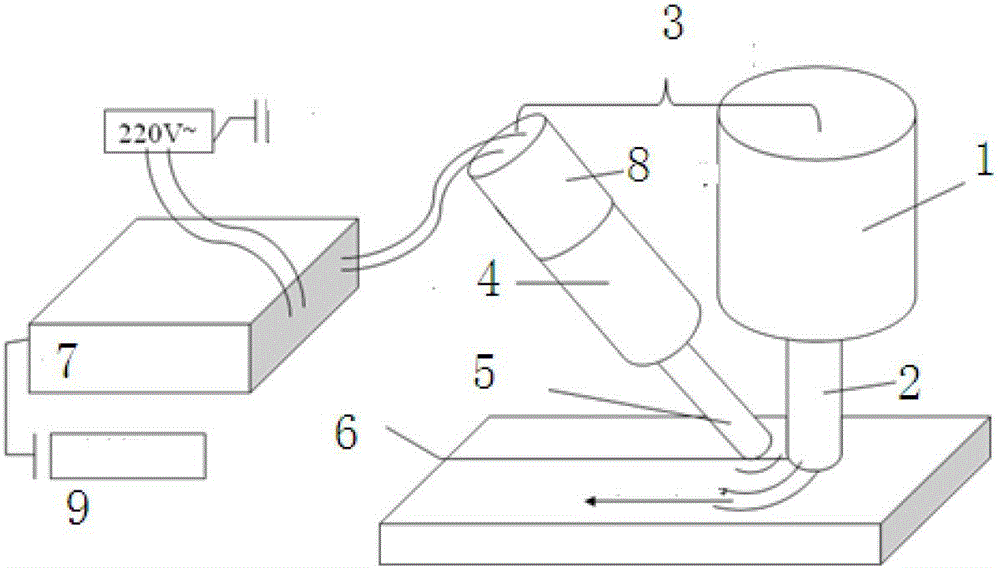

[0037] Ultrasonic vibration assisted friction stir welding device, including friction stir welding machine 1 with stirring head 2, ultrasonic generator 7, transducer 8, horn 4, tool head 5, ultrasonic generator 7 is connected to the vibration unit through a signal transmission line, The vibration unit includes a transducer 8, a horn 4, and a tool head 5. The transducer is connected to the horn, and the horn is connected to the tool head. Both are connected by studs. The ultrasonic vibration of the tool head The introduction point is in the area to be welded in front of the stirring head, and the vibration unit is fixed with the friction stir welding machine 1 through the positioning fixture 3 .

[0038]The positioning fixture includes a cuboid frame 10, a connecting piece 11, and a cylindrical fixture 12. The cuboid frame 10 includes a front splint 13 and a rear splint 14. Between the front splint 13 and the rear splint 14 is an upper baffle plate 20 of the friction stir weldin...

Embodiment 2

[0043] The ultrasonic vibration assisted friction stir welding device includes a friction stir welding machine 1 with a stirring head 2, an ultrasonic generator 7, a transducer 8, and a vibration unit. The ultrasonic generator 7 is connected to the vibration unit through the transducer 8. The vibration unit includes a transformer The horn 4 and the horn 4 are connected to the tool head 5. The ultrasonic vibration introduction point of the tool head 5 is in the area to be welded in front of the stirring head. The vibration unit is fixed with the friction stir welding machine 1 through the positioning fixture 3.

[0044] The positioning fixture includes a cuboid frame 10, a leading screw, and a cylindrical fixture 12. The cuboid frame 10 includes a front splint 13 and a rear splint 14. Between the front splint 13 and the rear splint 14 is a friction stir welding machine 1 upper baffle plate 20, The front and rear splints are tightly matched with the upper baffle plate of the fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com