Novel process and equipment for vulcanizing rubber inner tire

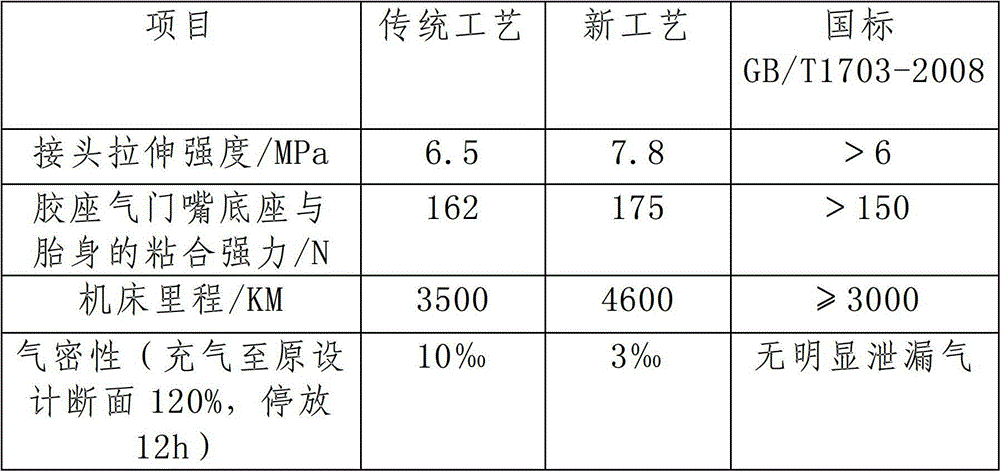

A rubber inner tube, a new technology, applied in the direction of tires, other household appliances, household appliances, etc., can solve the problems of partial sulfur deficiency in the tire body, insufficient adhesion strength of the mouth, internal and external cracks in the joints, etc., to reduce appearance defects , shorten the vulcanization time, improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1, a kind of rubber inner tube vulcanization new technique is characterized in that: after the compressed gas provided by the air compressor is degreased, dewatered, and oil-gas is separated, it is heated by a heat exchanger and passed into the inner tube in the vulcanizer, and the gas temperature is 180-185°C, the pressure is 0.8-1.00MPa, and the steam chamber outside the mold cavity of the vulcanizer uses 180-185°C heat transfer oil.

Embodiment 2

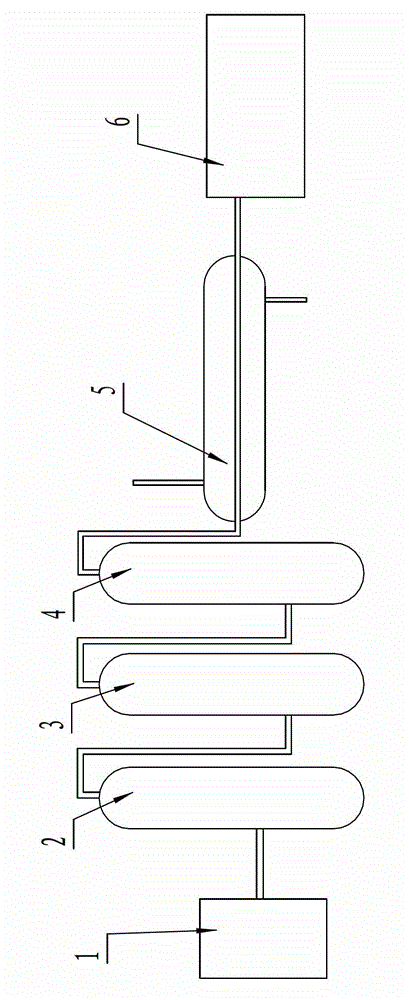

[0016] Embodiment 2, a kind of vulcanization equipment for rubber inner tube, is characterized in that: the air compressor 1 connected in sequence, the air storage tank A2 for oil discharge and drainage, the air storage tank B3, the oil-water separator 4, the oil-gas heat exchanger, Vulcanizing machine 6, and the oil-gas heat exchanger is casing type oil-gas heat exchanger 5.

[0017] The air nozzle of the vulcanizer is connected with the hot air outlet pipe of the oil-air heat exchanger to provide an internal pressure with a certain temperature for the semi-finished product; the outer air chamber of the vulcanizer mold cavity is equipped with heat transfer oil that provides a heat source for the semi-finished product.

[0018] The air at normal temperature is pressurized by the compressor to 0.8-1.00Mpa and sent to the air storage tank A for the first step of oil removal and water removal, and then through the air storage tank B for the second step of oil removal and water rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com