Production method for extracting active substances from beer lees

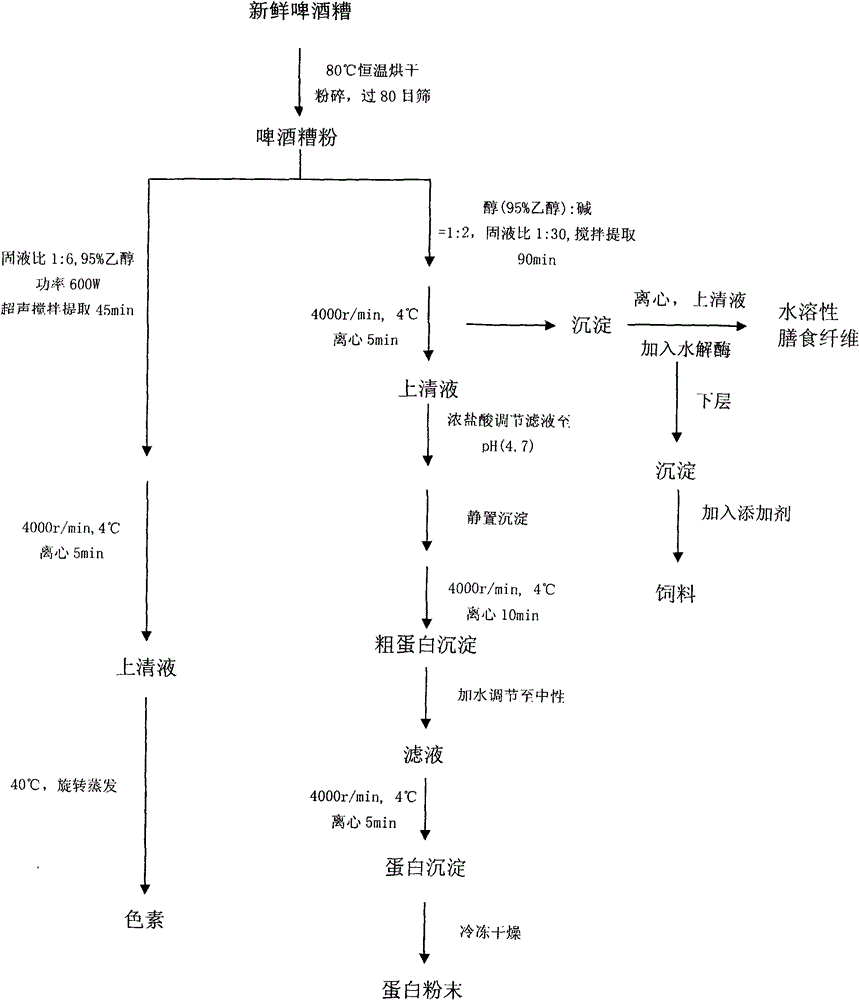

A production method and technology of active substances, applied in peptide preparation methods, chemical instruments and methods, animal feed, etc., can solve the problems of waste of active substances, low extraction rate, no further utilization of vinasse residue, etc., and meet the technological conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] After the wet distiller's grains are dried and crushed, accurately weigh 100 kg of distiller's grains powder, add 450 liters of ethanol solution with a concentration of 95% according to the ratio of solid to liquid ratio of 1:4.5, and extract the pigment in an ultrasonic cell pulverizer for 70 minutes. , ultrasonic power 744.00 kilowatts, centrifugation 4000 rpm, supernatant concentrated under reduced pressure to obtain 3.5 kg of pigment. Add the alcohol-alkali (1:3) solution to the lower layer of precipitate to extract the protein at 1:50 (Kg:l), stir, extract for 90 minutes, centrifuge for 15 minutes (4000 rpm), adjust the supernatant to pH 4.7 and then centrifuge 12 minutes (5000 rpm / min), 10.2 kilograms of protein was obtained, and the lower layer was precipitated to extract dietary fiber by alkali method, and 150 liters of sodium hydroxide (0.9%) was added according to a solid-liquid ratio of 1:17 (Kg:l), and heated in a water bath The temperature is 70°C, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com