Method for recovering water-soluble cutting fluid from silicon wafer cutting fluid

A technology for silicon wafer cutting liquid and silicon wafer cutting waste liquid, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of low cutting liquid efficiency and quality, poor recycling effect, low slicing efficiency, etc. Achieve the effect of improving the quality and production efficiency of silicon wafers, high utilization rate and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples.

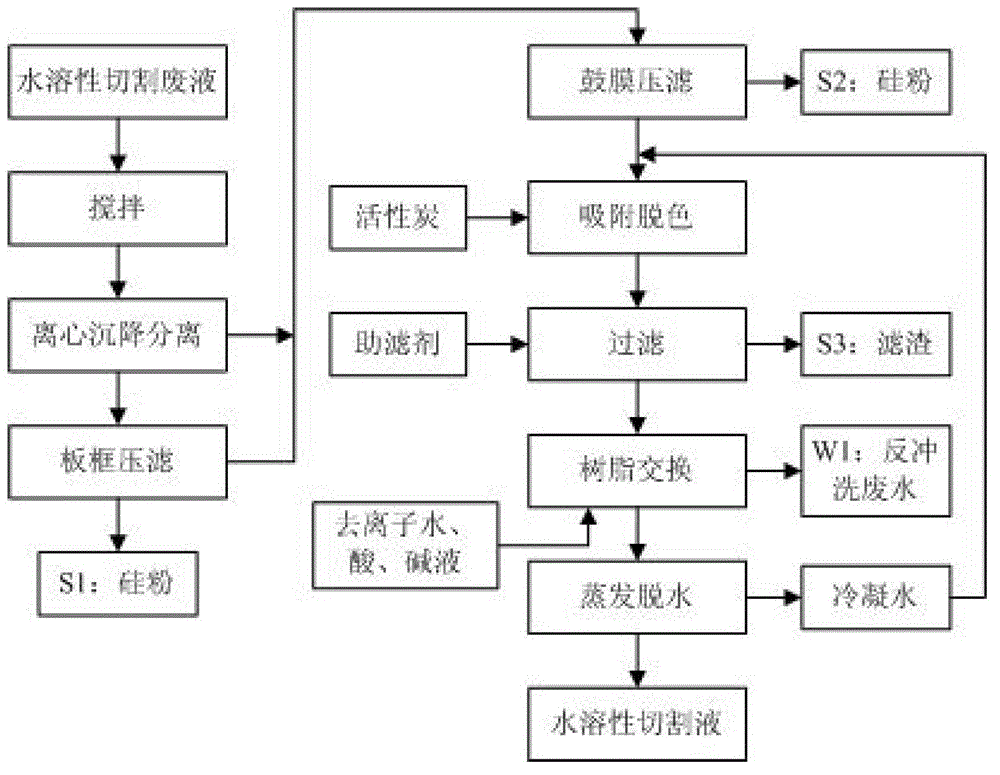

[0023] In order to solve the above-mentioned technical problems, a method for recovering the water-soluble cutting fluid in the silicon wafer cutting fluid of the present invention comprises the following steps:

[0024] A. Stir the silicon wafer cutting waste liquid evenly or add water to the silicon wafer cutting liquid for stirring. The stirring speed of the silicon wafer cutting liquid is 150-300r / min, and then separate the solid components and the semi-finished cutting liquid through a centrifugal sedimentation separator; The speed of the sedimentation separator is 700-900r / min; the silicon wafer cutting fluid is pumped into the waste liquid tank for stirring to reduce the suspension capacity of silicon powder in the waste water soluble cutting fluid, and the mixed liquid after stirring enters the centrifugal sedimentation separator , using centrifugation and gravity sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com