Novel building wallboard, building wall body structure and manufacturing method thereof

A technology for building walls and building walls, applied in the field of building interior walls and their assembly, can solve the problems of yellowing or mildew spots on the walls, large energy consumption, cumbersome production processes, etc., guaranteeing the construction period and reducing load-bearing. The effect of simple load and construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and several preferred embodiments.

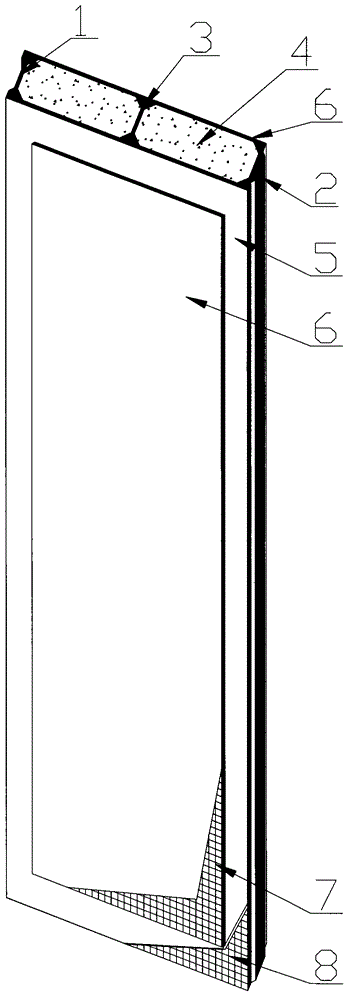

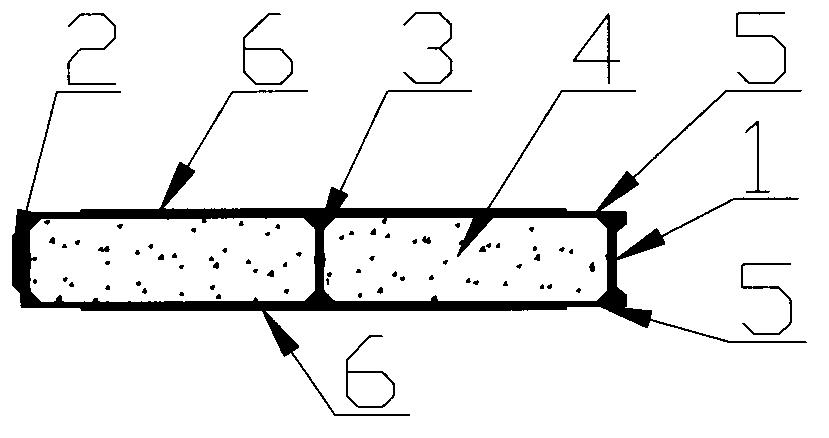

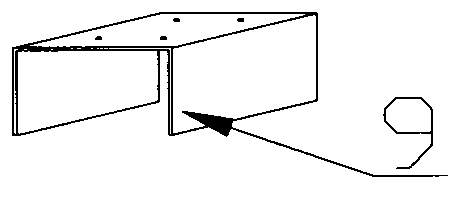

[0035] refer to Figure 1-7 , the new building wall panels include:

[0036] The wall panel shell 6 and the lightweight thermal insulation padding material 4 filled in the wall panel shell. The lightweight thermal insulation filling material includes foamed cement slurry, perlite, coarse grains of crop straw and flame retardant, etc., but is not limited thereto , as long as it is flame-retardant, non-toxic, environmentally friendly, and energy-saving lightweight condensate, it all belongs to the category of the present invention.

[0037] Preferably, the wallboard shell is a porous shell mainly composed of concrete materials such as cement mortar, especially magnesium oxychloride cement mortar, and the surface layer and the bottom layer of the wallboard shell are respectively provided with alkali-resistant m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com