High-sealing roller bit

A roller cone bit and high-sealing technology, which is applied in construction and other directions, can solve the problems that affect the life of sealing elements and the ability to adapt to temperature, the friction of sealing parts is small, and the assembly process is cumbersome, so as to achieve good product consistency and small sealing space , Reduce the effect of processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

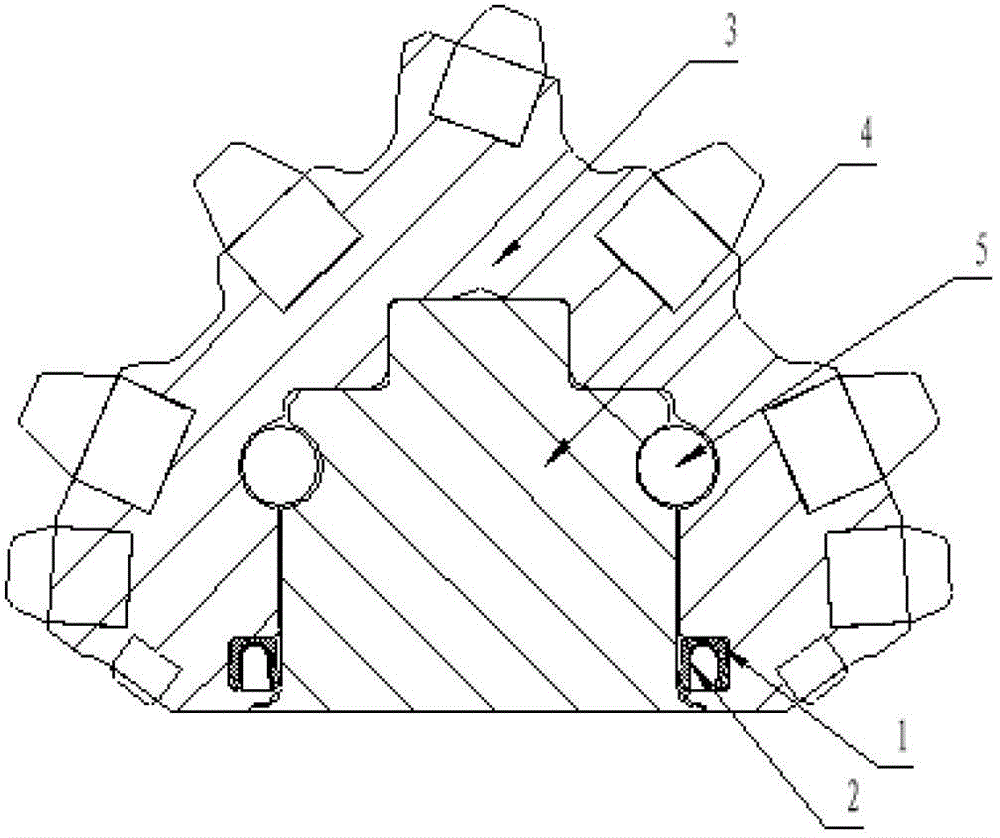

[0028] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 Shown: a high-tightness roller cone bit, including the cone 3 and the palm shaft 4, the cone and the palm shaft are locked together by the positioning steel ball 5 installed in the "R" shaped groove between the two , the two can only rotate radially and cannot slide axially. A sealing groove is provided near the opening of the cone shaft hole of the cone, and a sealing part is arranged in the sealing groove, and the sealing part is composed of a sealing jacket 1 and an energy storage spring 2, and the sealing part is sleeved on the accumulator can spring on.

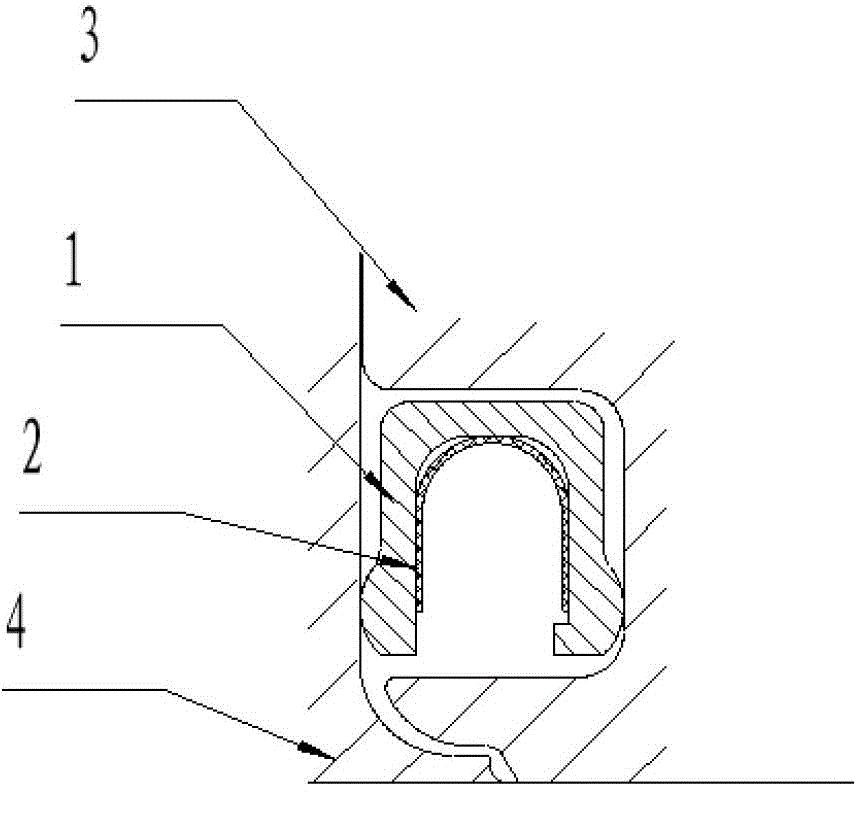

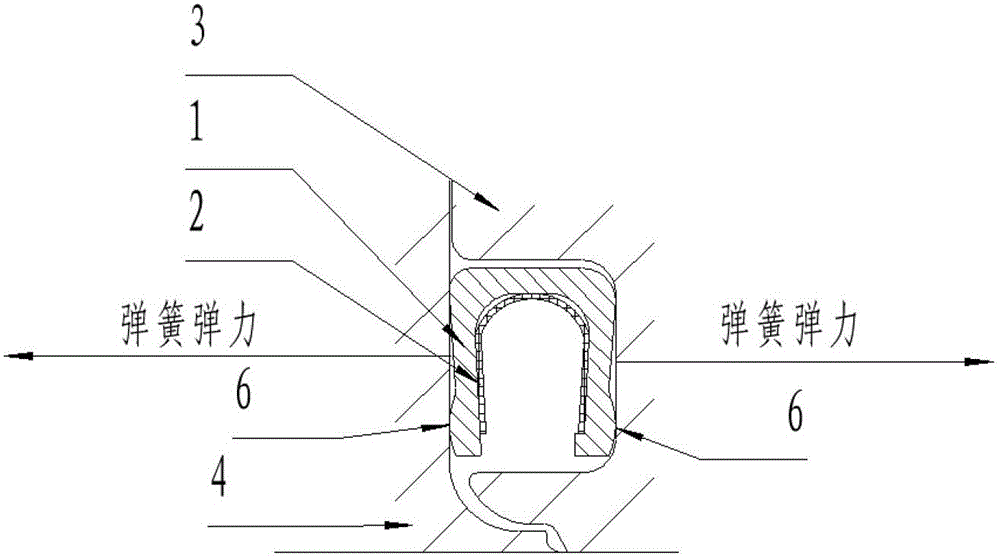

[0029] Such as figure 2 Shown is an enlarged view of the cross-sectional structure of the sealing component of the present invention in an unassembled state, and the cross-sectional shape of the sealing jacket is an inverted "U" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com