Alternative driving switching mechanism with linear reciprocating motion and rotating motion

A technology of linear reciprocating motion and rotary motion, applied in the direction of mechanical equipment, transmission devices, belts/chains/gears, etc., can solve problems such as reducing the pressure of gas explosion expansion, increasing the resistance of starting and changing speeds, and reducing the working efficiency of pistons, etc., to achieve Effects of reducing vibration and noise, improving conversion efficiency, and reducing external working power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

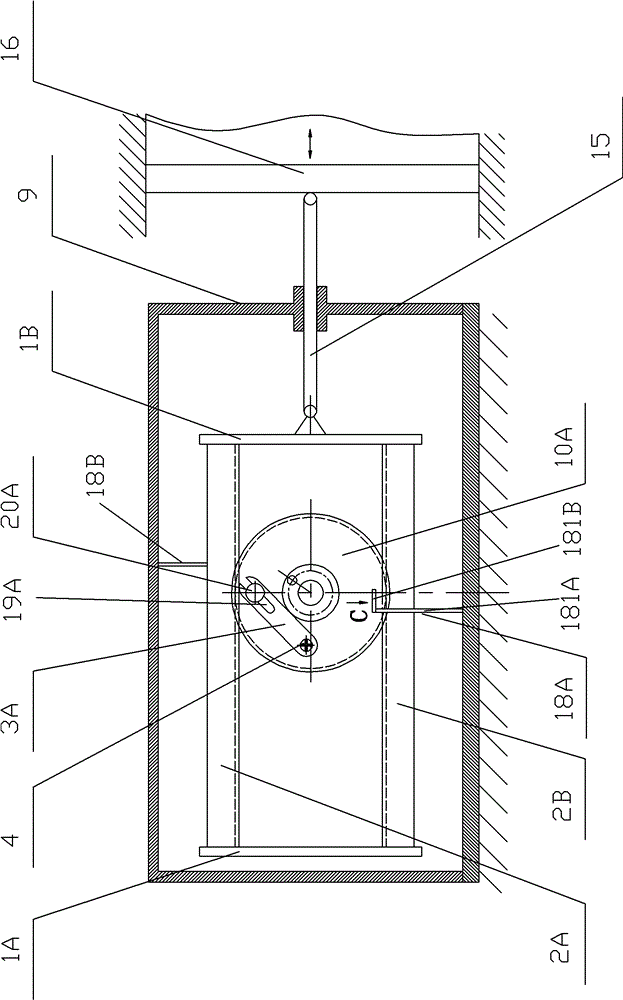

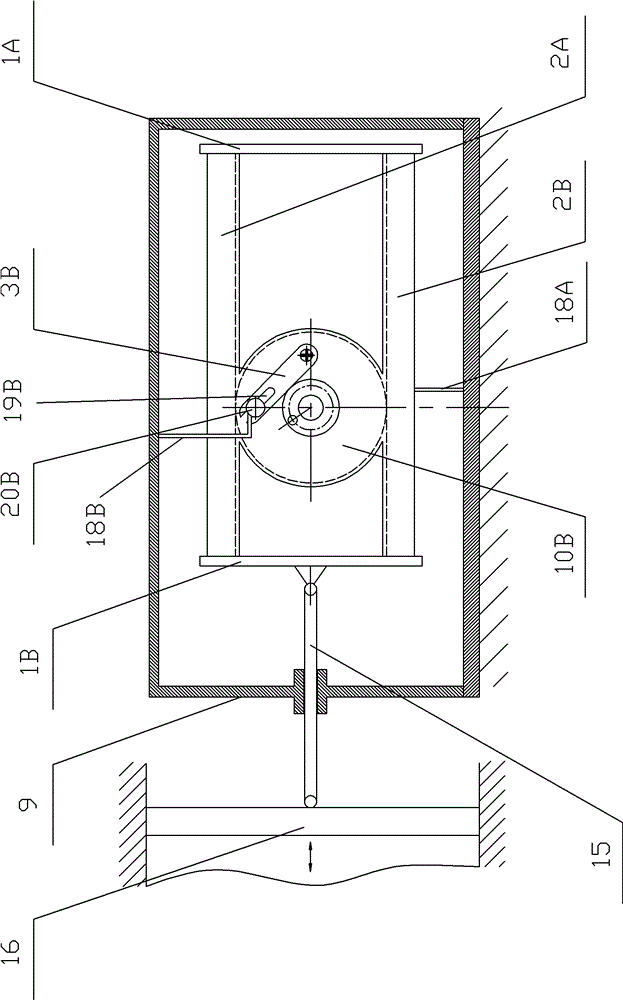

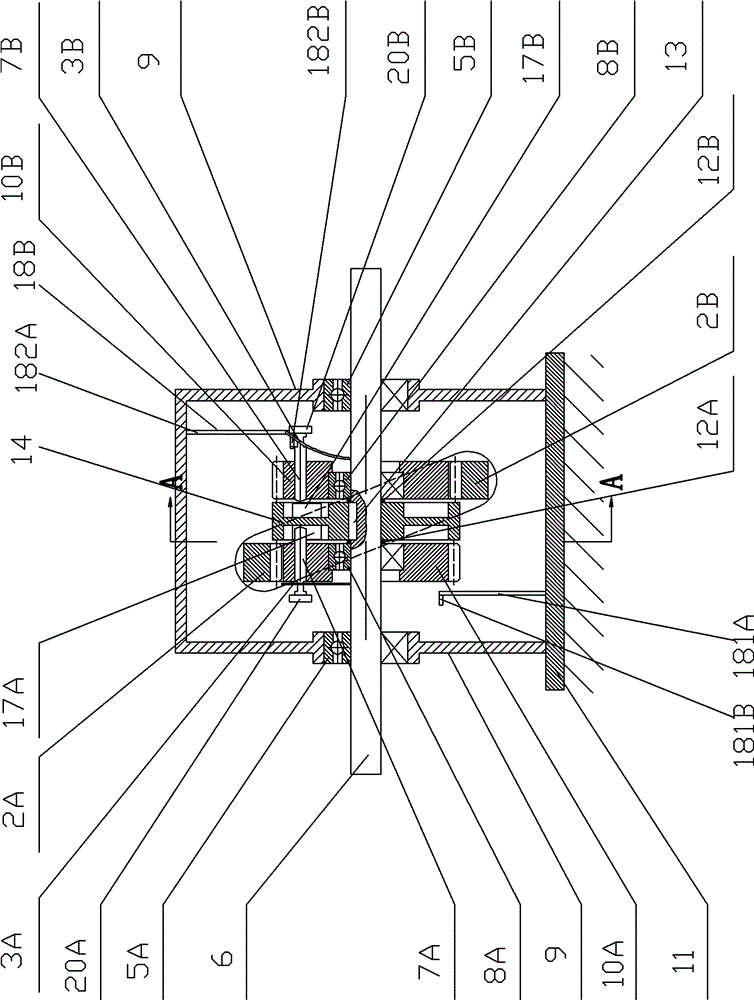

[0051] Such as Figure 2a , 2b , 2c, the second embodiment of the alternating drive conversion mechanism of linear reciprocating motion and rotary motion of the present invention differs from the first embodiment in that the first gear 10A' and the second gear 10B' are made into a semicircle The arc lengths of the first gear 10A' and the second gear 10B' can be set according to the linear reciprocating strokes of the first rack 2A and the second rack 2B respectively. Sliding pins 7A, 7B can be arranged on the edge positions of the first and second semicircular or fan-shaped gears respectively as shown in the figure, but it is better to be arranged on the center line of the semicircular or fan-shaped gears, so that the rotation of the gears will be more stable. The structure and movement process of the other parts of the second embodiment are the same as those of the first embodiment, and will not be repeated here.

[0052] Such as Figure 3a , 3b , 3c, 3d, and 3e, the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com