Thick glue photoetching electroforming technology-based manufacture method of three-dimensional MEMS (micro-electromechanical systems) supercapacitor

A technology for supercapacitors and manufacturing methods, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of increased integration of liquid electrolytes, low performance of supercapacitors, limited research on supercapacitors, etc., to achieve increased effective surface area, high energy Density, the effect of increasing specific energy and specific power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

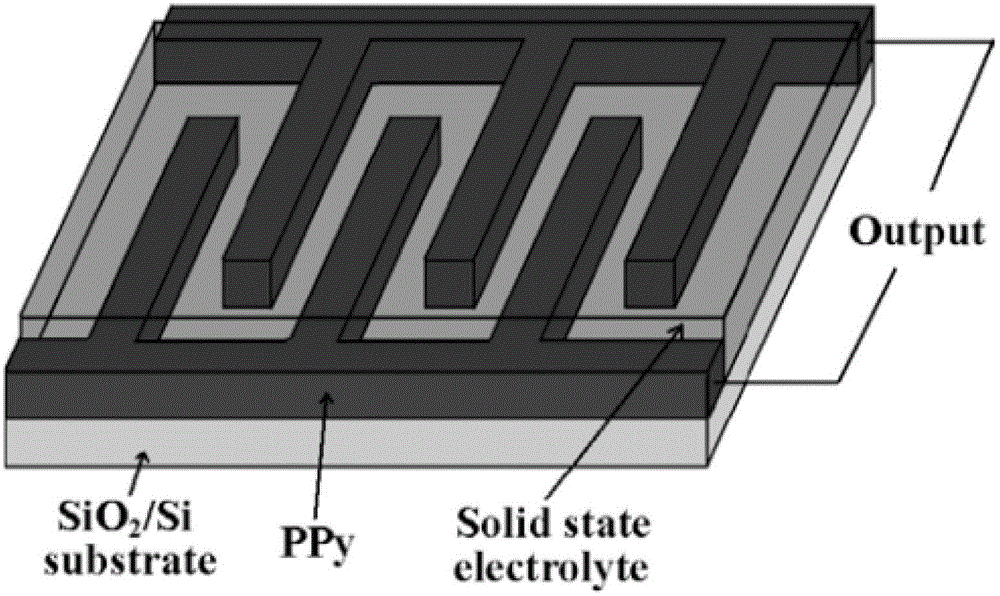

[0029] The structural representation of supercapacitor example of the present invention is as figure 1 shown.

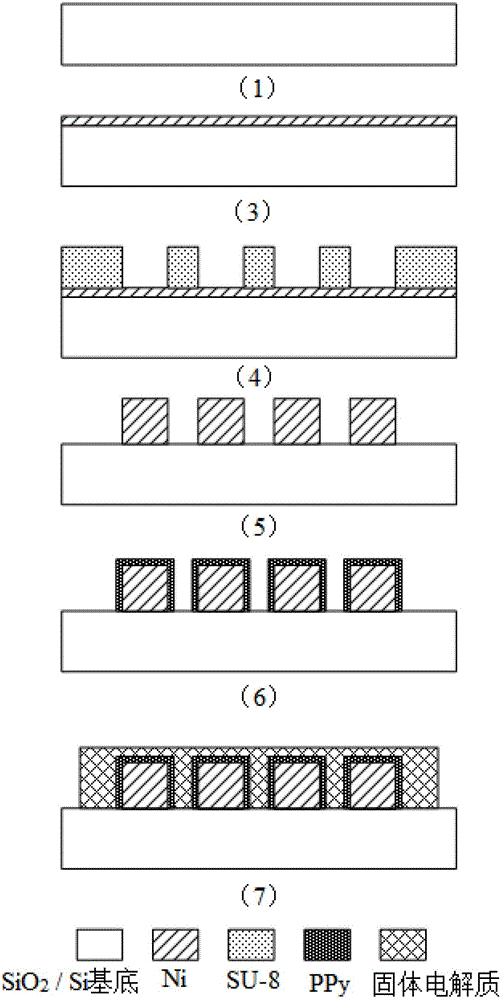

[0030] Such as figure 2 Shown, based on thick glue photolithography electroforming process three-dimensional MEMS supercapacitor manufacturing method, comprises the following steps:

[0031] (1) Select a 4-inch silicon wafer as the substrate, and wash the silicon wafer in xylene, acetone, alcohol, sulfuric acid / hydrogen peroxide, ammonia / hydrogen peroxide, hydrochloric acid / hydrogen peroxide solution to remove oil, oxide film and metal ions.

[0032] (2) Put the silicon wafer cleaned in step (1) into an oxidation furnace for wet thermal oxidation for 10 hours, and the thickness of the oxide layer is 1.5 microns.

[0033] (3) On the silicon wafer oxidized in step (2), a layer of nickel with a thickness of 300 nanometers is sputtered by radio frequency magnetron as an electroforming seed layer.

[0034] (4) Apply a layer of Microchem's SU-8 photoresist on the nicke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com