Laminates for flexible wiring boards

A technology of flexible wiring boards and laminates, applied in layered products, metal layered products, circuit substrate materials, etc., can solve the problem of inability to conduct with the other side, inability to increase wiring density, and inability to conduct with through holes and other problems, to achieve the effect of high bendability and improve bendability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] A 27.5 μm-thick polyimide resin with an adhesive is used as an insulating resin substrate. In addition, a 18-μm-thick rolled sheet containing 0.02 mass % of Ag, 0.02 mass % of oxygen, and the balance of Cu and unavoidable impurities is used. Copper foil is used as copper foil. Rolled copper foil was arranged on one surface of the polyimide resin, and joined by thermocompression bonding at 180° C. for 60 minutes.

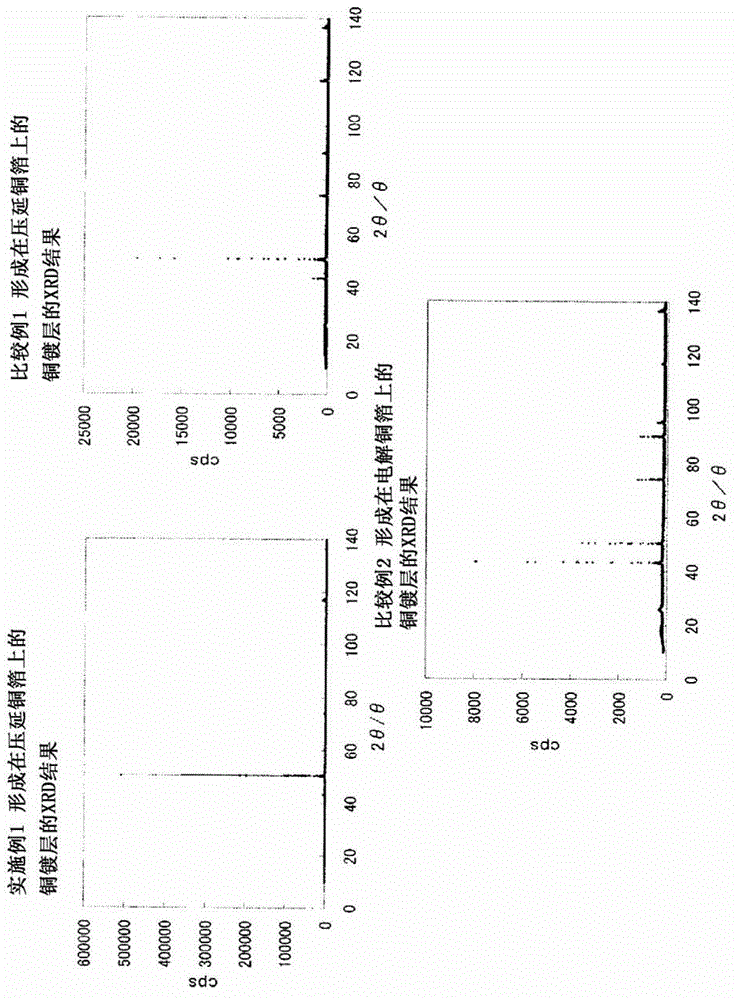

[0076] Next, under the above copper plating conditions, at 1A / dm 2 A current density of 10 μm thick copper was formed on a single-sided rolled copper foil glued to polyimide resin. In addition, the thickness of this plating layer was calculated by subtracting the thickness of each known resin film and copper foil from the thickness (total thickness) of the laminated body for flexible wiring boards of the whole.

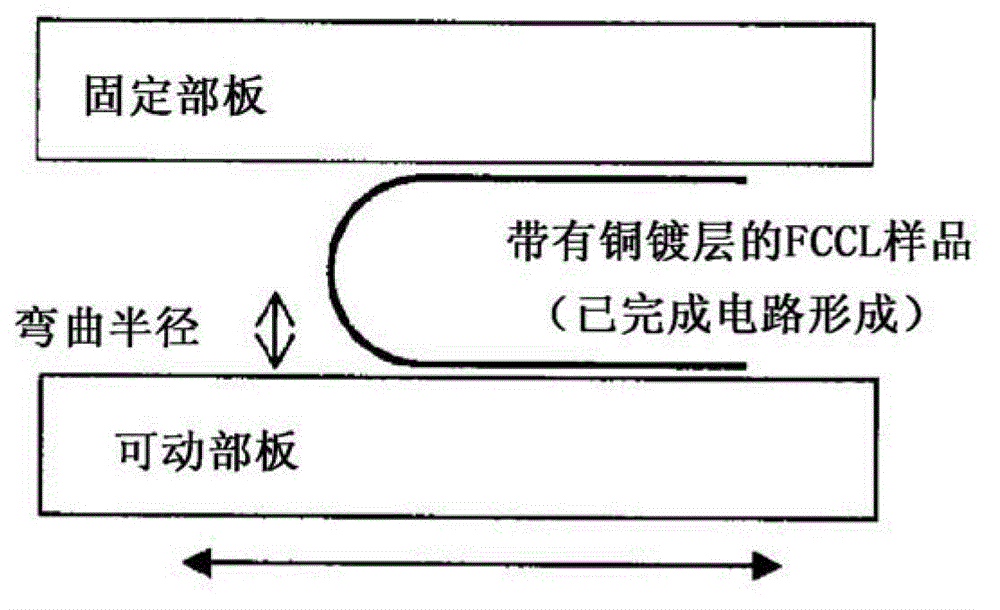

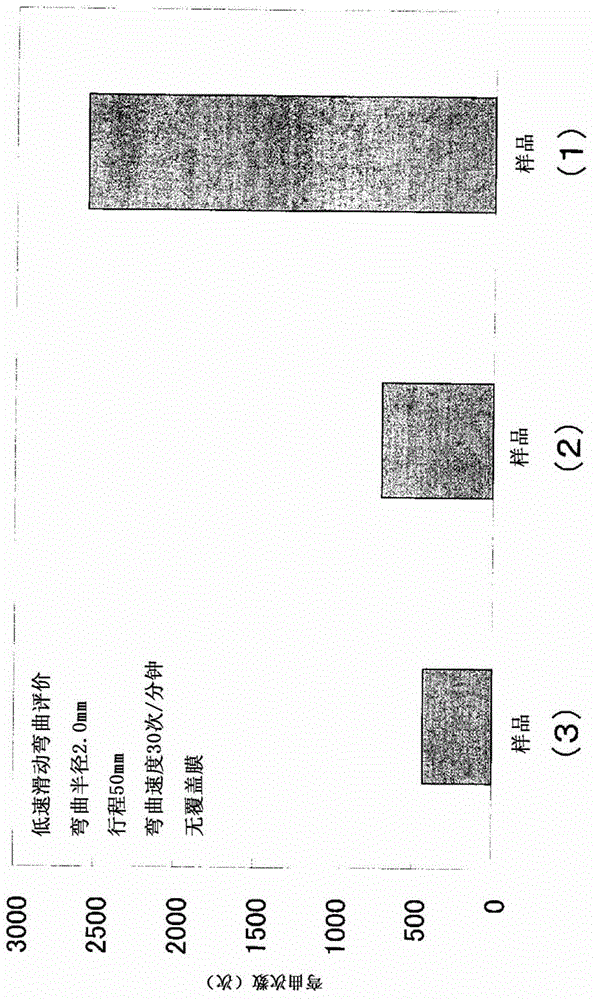

[0077] A 1 cm x 1 cm square laminate sheet for a flexible wiring board was cut out from the sample sheet of the laminate for a flexible wiring boar...

Embodiment 2

[0085] A 27.5 μm-thick polyimide resin with an adhesive is used as an insulating resin substrate. In addition, a 18-μm-thick rolled sheet containing 0.02 mass % of Ag, 0.02 mass % of oxygen, and the balance of Cu and unavoidable impurities is used. Copper foil is used as copper foil. Rolled copper foil was arranged on one surface of the polyimide resin, and joined by thermocompression bonding at 180° C. for 60 minutes.

[0086] Next, under the above copper plating conditions, at 4A / dm 2 A current density of 10 μm thick copper was formed on a single-sided rolled copper foil glued to polyimide resin. In addition, the thickness of this plating layer was calculated by subtracting the thickness of each known resin film and copper foil from the thickness (total thickness) of the laminated body for flexible wiring boards of the whole.

[0087] A 1 cm x 1 cm square laminate sheet for a flexible wiring board was cut out from the sample sheet of the laminate for a flexible wiring boar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com