A modification method for high-end wood

A wood and modification technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problem of few high-end research on wood, and achieve the effect of consistent and uniform color inside and outside the wood, improving performance, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

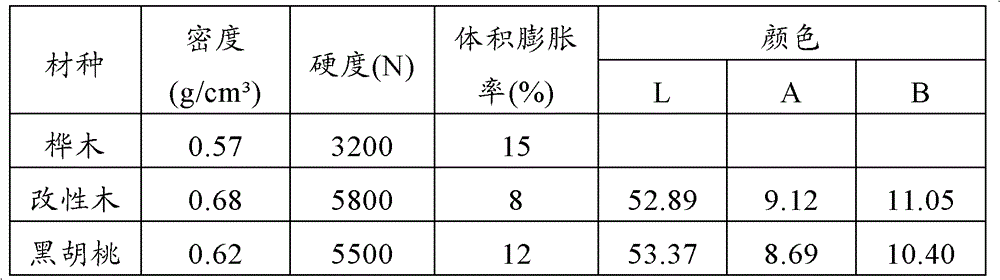

[0021] One, preparation imitates the wood dyestuff of black walnut color; Two, select birch as test material; Three, select the melamine modified urea-formaldehyde resin (hereinafter referred to as modified resin) that molecular weight is about 500; Four, 0.4 part of black walnut dye, change Mix 40 parts of resin, 44.3 parts of water, 5 parts of ethanol, and 0.3 parts of sodium alkylbenzene sulfonate to make a modified liquid; 5. Vacuum pressure impregnation treatment: vacuumize to a vacuum degree of 0.085 ~ 0.09Mpa, keep for 30min, Use 2.0Mpa in the pressurization stage and keep it for 120 minutes; 6. Dry the treated birch to a moisture content of 10%-12%.

[0022] Among them, the melamine-modified low-molecular-weight urea-formaldehyde resin is synthesized according to the following steps: 1) Add 100 parts of formaldehyde aqueous solution to the reaction kettle successively, adjust the pH to 9.0-10.0 with aqueous sodium hydroxide solution, add 90 parts of melamine, and then h...

Embodiment 2

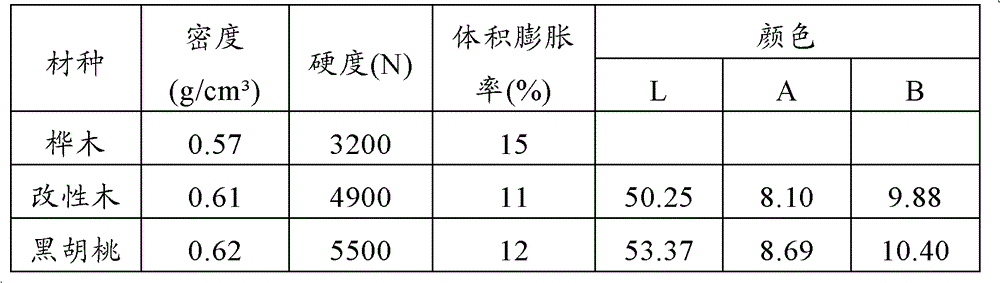

[0027] The only difference between this embodiment and Example 1 is: 0.4 parts of black walnut dye, 20 parts of modified resin, 54.3 parts of water, 5 parts of ethanol, and 0.3 parts of sodium alkylbenzene sulfonate are uniformly mixed to make a modified liquid; Steps and parameters are exactly the same as in Example 1.

[0028] The performance comparison of the modified wood prepared in this embodiment is shown in Table 2

[0029] Table 2 Comparison of properties of modified wood

[0030]

Embodiment 3

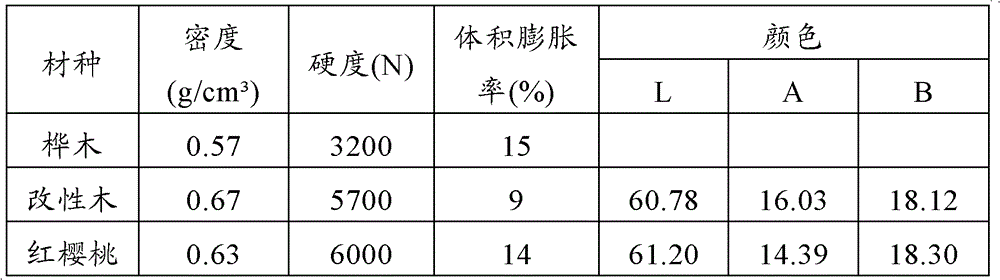

[0032] The only difference between present embodiment and embodiment 1 is: the wood dye of imitation red cherry color is prepared; other steps and parameters are exactly the same as embodiment 1.

[0033] The performance comparison of the modified wood prepared in this embodiment is shown in Table 3

[0034] Table 3 Comparison of properties of modified wood

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com