Method for enabling fully mechanized face to directly pass through collapse pillar by drilling weakened rock

A fully-mechanized mining face and collapse column technology, which is applied in earthwork drilling, ground mining, underground mining, etc., can solve the problems of poor economic practicability, complicated process, long time period, etc., achieve less coal loss, ensure normal advancement, The effect of reducing skipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0029] Implementation of a kind of drilling weakening rock provided by the present invention makes the fully mechanized mining face directly pass the method for the collapse column, and its described method is carried out according to the following steps:

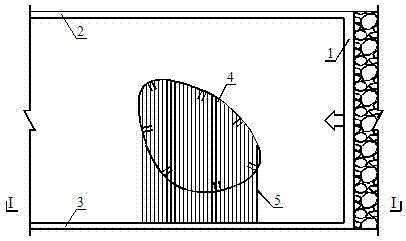

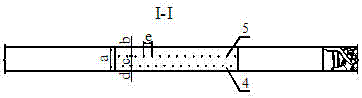

[0030] Step 1, such as figure 2 and image 3 As mentioned above, the geophysical prospecting method is used to measure the geological conditions in front of the fully-mechanized mining face of a certain mine by using a proton precession magnetometer. During the measurement process, the probe is perpendicular to the direction of the geomagnetic field. It has been determined that the shape of the collapse column 4 is approximately elliptical, with a major axis of 116m and a short axis of 77m, and the distance between the collapse column 4 and the return air trough 3 is 26.5m.

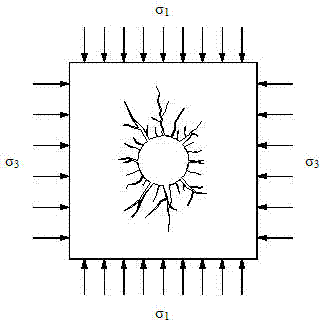

[0031] Step 2: Drilling and sampling the collapsed column rock, making the rock sample into a standard test piece, and measuring the uniaxial compre...

Embodiment approach 2

[0036] Step 1. Reference Figure 4 and Figure 5 , through the drilling method, it is determined that the shape of the collapse column 4 is approximately elliptical, its major axis is 96m, and its short axis is 67m.

[0037] Step 2: Drilling and sampling the collapsed pillar rock, making the rock sample into a standard test piece, and measuring the uniaxial compressive strength of the rock on an electro-hydraulic servo universal testing machine is 23.7MPa.

[0038] Step 3: Drill out the borehole according to the installation requirements of the borehole stress gauge, and send the pressure pillow into the hole according to the predetermined direction. Fill oil into the pressure pillow to make it expand, and when it reaches and stabilizes at the set pressure value, close the oil injection valve and observe. The peak abutment pressure of the fully mechanized mining face is determined to be 52.9MPa; the range of abutment pressure affected by mining is 0m~70m, and the abutment pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com