Platinum-tantalum laminated composite material and preparation method thereof

A layered composite material and plate technology, applied in the field of composite materials, can solve problems such as poor high-temperature mechanical properties, limited application, and inability to use high-temperature structural materials, and achieve high-temperature strength, high-temperature creep resistance, and good high-temperature mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

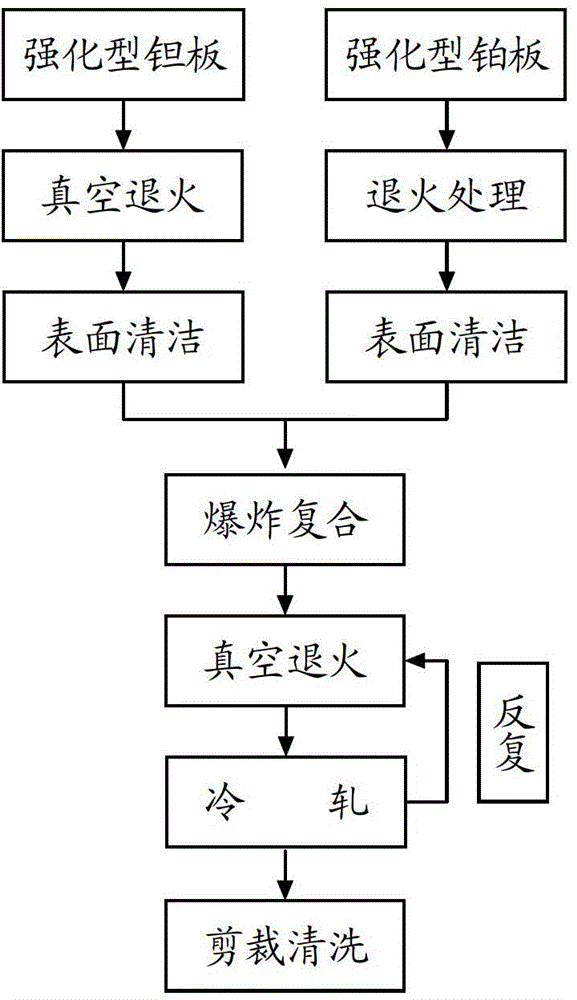

[0041] The invention discloses a method for preparing a platinum-tantalum layered composite material, such as figure 1 As shown, the process flow chart of the platinum-tantalum layered composite material includes the following steps: step a) explosively compounding the reinforced tantalum plate and the first reinforced platinum plate to obtain an intermediate plate, and the reinforced tantalum plate is solid A solution strengthened tantalum plate and / or a dispersion strengthened tantalum plate, the first strengthened platinum plate is a first solid solution strengthened platinum plate and / or a first dispersion strengthened platinum plate, the first strengthened platinum plate The thickness ratio to the reinforced tantalum plate is 1 to 5: 5 to 9; step b) rolling the intermediate plate and annealing treatment to obtain a platinum-tantalum layered composite material.

[0042] As a preferred solution, it also includes a pretreatment step of the reinforced tantalum plate, specifically...

Embodiment 1

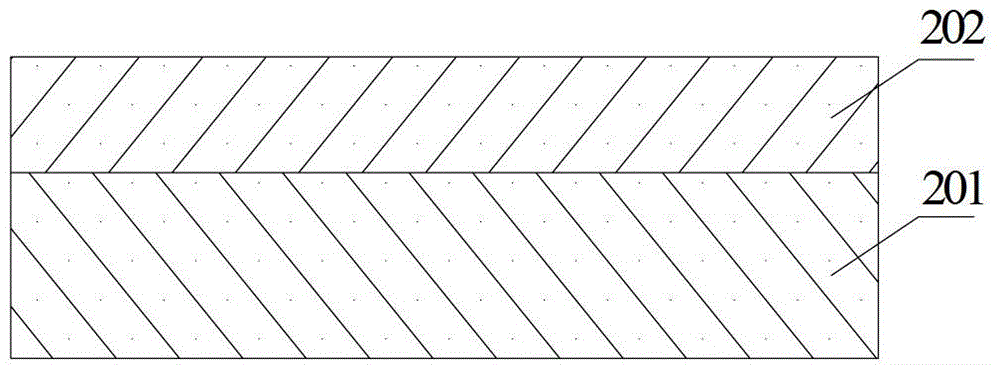

[0066] Take the reinforced platinum / reinforced tantalum double-layer metal composite plate as an example for illustration. The base layer is a Ta-W reinforced plate and the clad layer is a Pt-Rh alloy plate.

[0067] (1) Preparation of raw materials Take a reinforced Ta-10W sheet with a thickness of 9mm prepared by vacuum melting, cut into a 9×70×150mm sheet as a substrate, and then take a sheet with a thickness of 1mm prepared by the intermediate frequency vacuum induction melting method Reinforced Pt-10Rh alloy sheet, cut into 1×70×150mm sheet as a composite sheet.

[0068] (2) Annealing treatment of the sheet A vacuum heat treatment furnace is used to anneal the tantalum sheet and the platinum sheet of step (1). Tantalum plate annealing process: first control the vacuum degree of the heating chamber to 2.6×10 -3 Pa below, then start to heat up, the holding temperature is 1200℃, the holding time is 50min, and it is cooled with the furnace; the platinum plate annealing process: th...

Embodiment 2

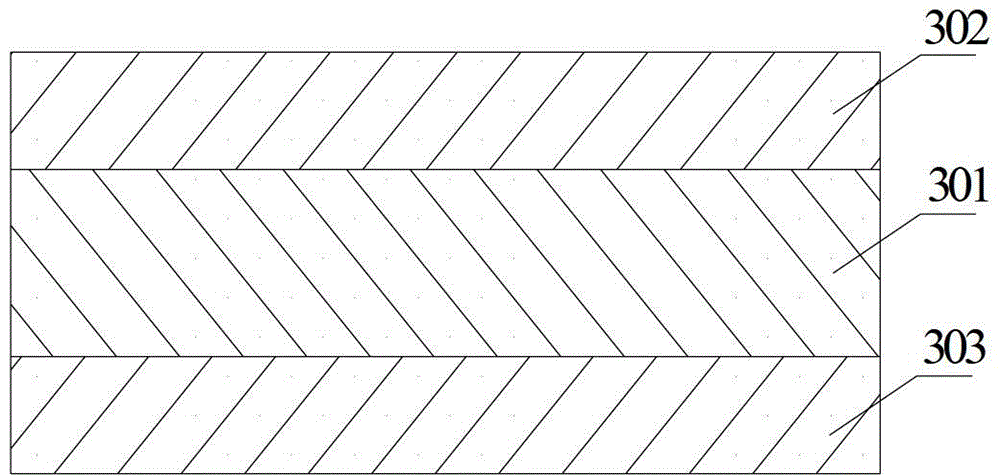

[0076] Take the dispersion-strengthened platinum alloy / strengthened tantalum / dispersion-strengthened platinum alloy three-layer metal composite plate as an example for illustration. The base layer is a Ta-Nb strengthened plate and the clad layer is a dispersion strengthened Pt-Rh alloy plate.

[0077] (1) Preparation of raw materials Take a reinforced Ta-Nb sheet with a thickness of 8mm prepared by vacuum melting, cut into a 8×100×150mm sheet as a substrate, and then take two sheets prepared by an intermediate frequency vacuum induction melting method with a thickness of 2mm The dispersion strengthened Pt-5wt%Rh alloy sheet is cut into 1×100×150mm sheet as a composite sheet.

[0078] (2) Annealing treatment of the sheet A vacuum heat treatment furnace is used to anneal the tantalum sheet and the platinum sheet of step (1). Tantalum plate annealing process: first control the vacuum degree of the heating chamber to 2.0×10 -3 Pa, the heating temperature can be started, the holding tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com