Glass cutting method by laser self-focusing and wire feeding

A glass cutting and self-focusing technology, applied in the physical field, can solve the problems of thermal stress, low cutting efficiency, limited thickness of cut glass, etc., and achieve the effect of high cutting precision, low cost and high quality of cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

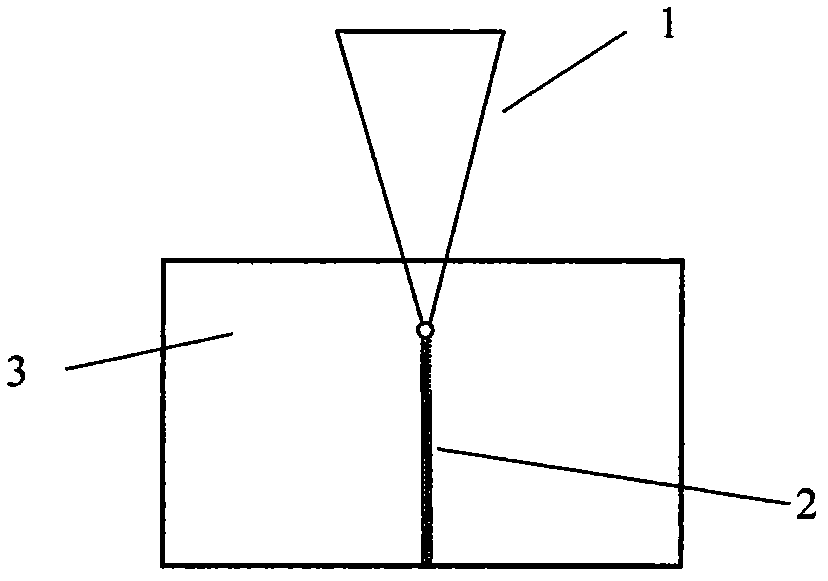

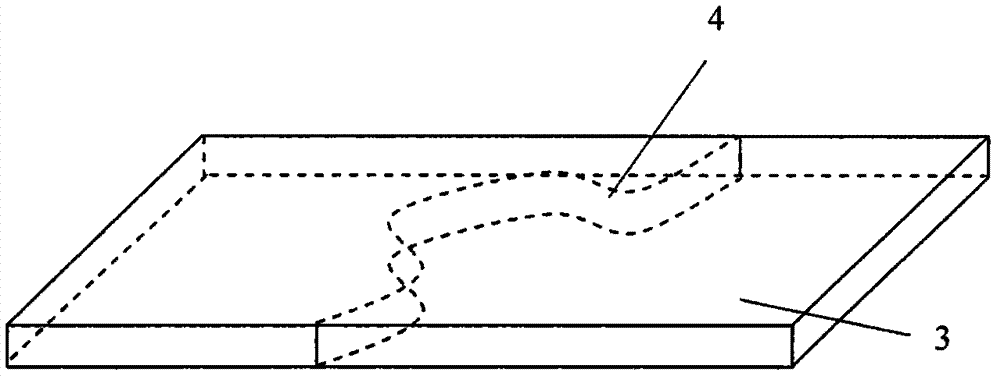

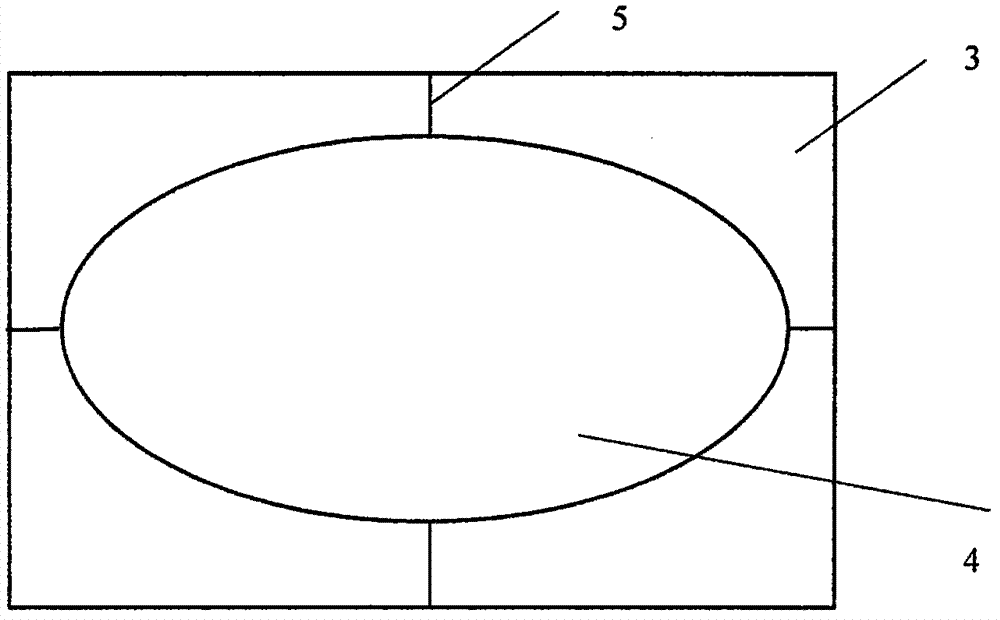

[0018] Such as figure 1 As shown, the laser self-focusing threaded glass cutting method of the present invention includes a step of focusing the laser beam 1 and then acting on the glass 3 and a step of breaking the glass 3 by thermal stress, mechanical external force or chemical method , wherein, in the step of focusing the laser beam 1 and then acting on the glass 3, the laser beam 1 is focused into the interior of the glass 3, causing the internal refractive index of the glass 3 to change, and then using the laser wave array The distortion that occurs on the surface produces laser self-focusing, and the laser energy near the focus formed by laser self-focusing produces multi-photon absorption ionization breakdown damage inside the glass 3, forming long filament damage cracks 2, such as figure 2 As shown, the laser beam 1 is moved along the cutting path, the long filament damage crack 2 is expanded into a thin ribbon-shaped damage crack 4, the height of the focus formed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com