Method for preparing benzyl benzoate by oxidizing dibenzyl ether

A technology of benzyl benzoate and oxidized dibenzyl ether, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve the problems of rarely used, high cost, and limited application fields, and achieves the goal of preparing Low cost and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 445g of dibenzyl ether (purity: 89.54%) into the oxidation kettle equipped with a separation tower, heat it, and when the temperature of the kettle rises to about 200°C, start to introduce air, and the air flow rate is 0.15m 3 / h. When the temperature of the kettle rises to about 230°C and there is almost no output from the top of the fractionation tower, close the air inlet valve, and take a kettle sample for analysis. The kettle sample contains 4.56% benzoic acid, 2.72% dibenzyl ether, and benzyl benzoate. Esters 84.42%. Transfer all the liquid from the still to a rectifying still, heat it, and collect fractions at 145-160°C to obtain 186 g of crude benzyl ester, which contains 2.36% benzoic acid, 0.86% dibenzyl ether, and 95.33% benzyl ester. The crude product was neutralized, cooled and crystallized, and separated to obtain 244 g of crystals. The composition was as follows: benzoic acid 0.089ml / 0.1N NaOH / g, dibenzyl ether 0.32%, and benzyl ester 99.58%.

Embodiment 2

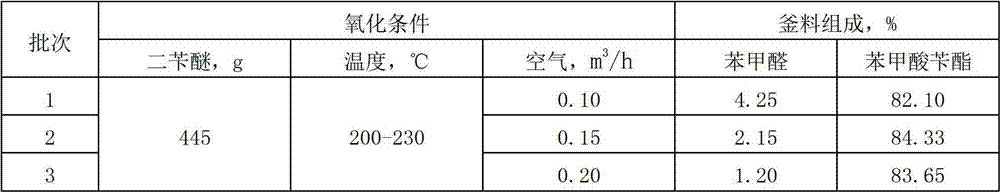

[0027] According to the same dibenzyl ether consumption and temperature of reaction of embodiment 1, investigate the impact of different air consumptions on the ratio of gained benzaldehyde and benzyl benzoate, as shown in table 1:

[0028] Table 1

[0029]

Embodiment 3

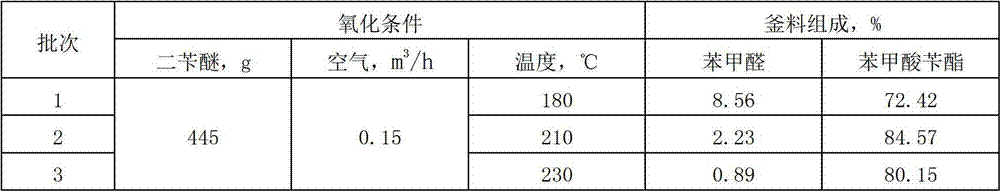

[0031] According to the same raw material consumption of embodiment 1, investigate the impact of different oxidation temperatures on the ratio of gained benzaldehyde and benzyl benzoate, as shown in table 2:

[0032] Table 2

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com