Tunnel kiln reduction roasting method of high-valence manganese oxide ores

A technology of manganese oxide ore and tunnel kiln, which is applied in the field of metallurgy, can solve problems such as difficult processing, difficult gas handling, and difficulty in ensuring the temperature of the material layer, and achieves the effects of simple process and equipment, high manganese conversion rate, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A mixture of pyrolusite and coromanganite with a Mn grade of 41.2% and a sulfur with a mass percentage of -1.0mm accounting for 80% of the mass percentage of -1.0mm is 1:0.05 by mass The ratio is mixed evenly to obtain the mixture; it is placed in the feed bin provided at the feed port of the tunnel kiln;

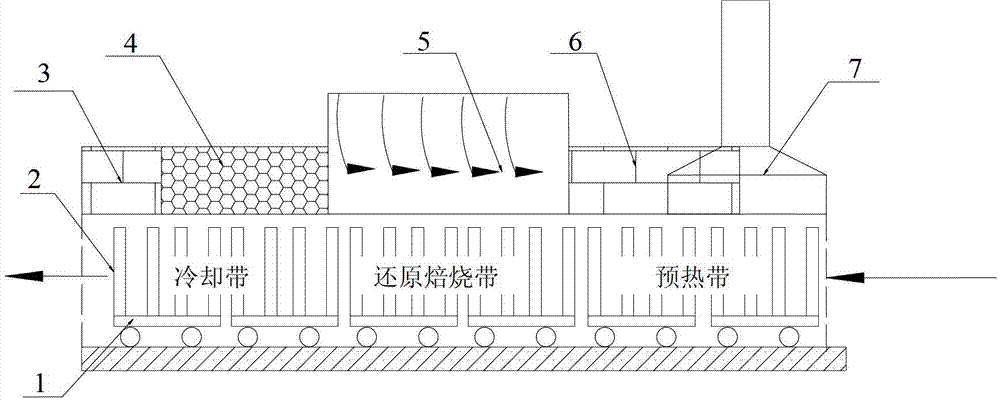

[0041] One end of the tunnel kiln is the feed port, and the other end is the discharge port. Between the feed port and the discharge port are the preheating zone 6 with the induced draft fan 7, the reduction roasting zone 5 with the burner and the The cooling zone of the kiln tail fan 3; a plurality of burners are respectively arranged on the two side walls of the tunnel kiln of the reduction roasting zone 5, and the kiln car 1 is embedded on the track in the tunnel kiln. The distributor under the feeding bin sends the mixed material into the stainless steel cylindrical closed reaction tank 2 installed on the kiln car 1, and the kiln car is sent to the preheating zon...

Embodiment 2

[0044] The mass percentage of -1mm particle size is 88.5%, the mixture of pyrolusite, coromanganese ore and black manganese ore with a Mn grade of 36.8% and industrial sulfur are uniformly mixed in a mass ratio of 1:0.15, and the preheating temperature is 300 ° C. The preheating time is 7 minutes; the reduction roasting temperature is 630°C, and the roasting time is 15 minutes; after the roasted product is cooled to a temperature lower than 100°C, it is leached with a dilute sulfuric acid solution with a mass concentration of 18%, and the leaching rate of manganese is 92.1%.

Embodiment 3

[0046] The mass percentage of -1mm particle size is 92%, the mixture of pyrolusite, hard manganese ore, black manganese ore and brown manganese ore with a Mn grade of 30.2% and industrial sulfur are uniformly mixed in a mass ratio of 1:0.20, and the preheating temperature is 310°C, preheating time 6min; reduction roasting temperature 700°C, roasting time 10min; after the roasted product is cooled to a temperature lower than 100°C, it is leached with a dilute sulfuric acid solution with a mass concentration of 22%, and the leaching rate of manganese is 94.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com