Method for manufacturing high-growth-rate LED (light-emitting diode) with P-type GaN structure

A technology of growth rate and manufacturing method, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor crystal quality and low luminous efficiency of quantum wells, and achieve the goal of reducing growth time, improving light extraction efficiency, and improving crystal quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

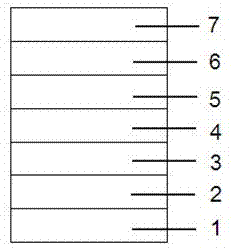

[0020] Such as figure 1 The LED epitaxial structure shown includes: a substrate 1 , a low-temperature GaN buffer layer 2 , a high-temperature GaN buffer layer 3 , an N-type GaN layer 4 , a shallow quantum well 5 , a light-emitting layer multi-quantum well 6 and a p-type GaN layer 7 .

[0021] The specific steps of the manufacturing method of the P-type GaN structure LED with high growth rate are as follows:

[0022] The substrate is annealed in a hydrogen atmosphere, the surface of the substrate is cleaned, the temperature is controlled between 1030-1200°C, and then nitrided. The substrate is a material suitable for the growth of GaN and its semiconductor epitaxial materials, such as Sapphire, GaN single crystal, single crystal silicon, silicon carbide single crystal, etc.;

[0023] Lower the temperature to 500-650°C to grow a low-temperature GaN buffer layer with a thickness of 20-30 nm. During this growth process, the growth pressure is controlled between 300-760 Torr, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com