Method of high power ytterbium doped fiber laser of neodymium-doped fiber laser pump

A fiber laser and ytterbium-doped fiber technology, used in lasers, laser parts, phonon exciters, etc., can solve the problem of reducing the thermal load density of the fiber, and achieve the effect of increasing the maximum output power, reducing the system cost, and improving the brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

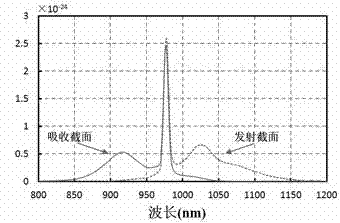

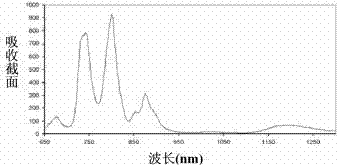

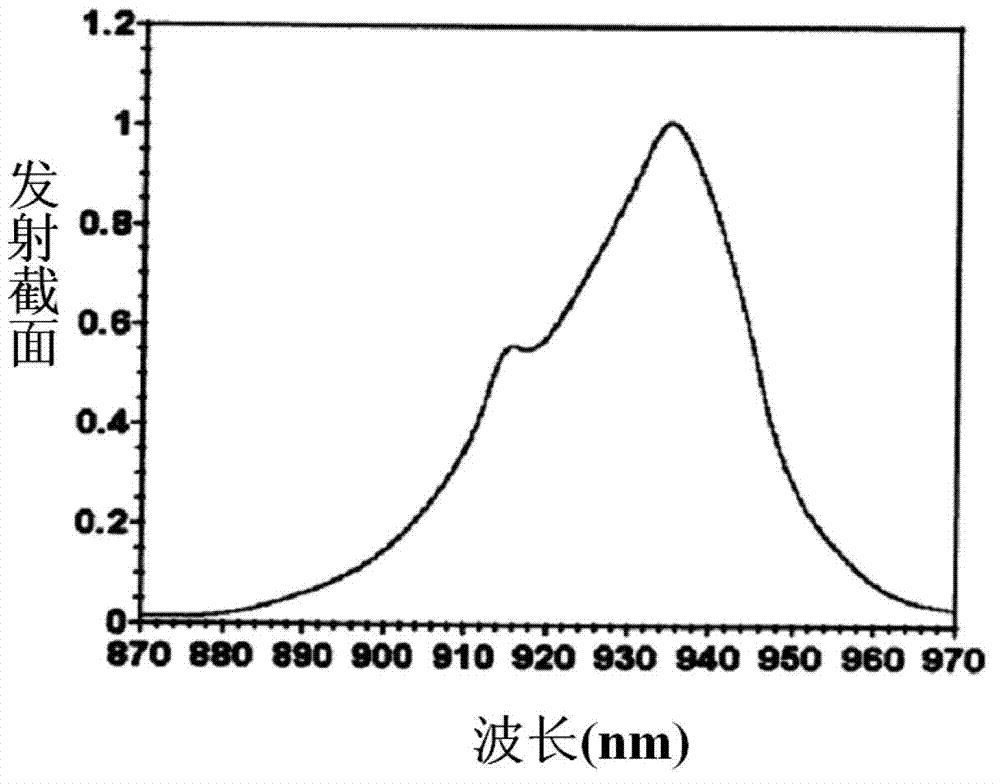

[0015] The present invention will be further described below in conjunction with the drawings. Figure 4 Shown is a schematic diagram of the structure of a neodymium-doped fiber laser with a center wavelength of 920-960 nm generated by pumping a neodymium-doped fiber with a center wavelength of about 808 nm. Among them, 1 is a neodymium-doped fiber laser with a central wavelength between 920-960 nm. The internal structure of the neodymium-doped fiber laser is that there are N semiconductor lasers with a central wavelength of about 808 nm (N is an integer greater than 1) , behind the semiconductor laser is an N×1 pump combiner I with a center wavelength of 808 nm, after the N×1 pump combiner I is a fiber grating I131, behind the fiber Bragg grating I is a neodymium-doped fiber 14, doped After the neodymium fiber is fiber grating II132. Among them, between the N semiconductor lasers and the pump beam combiner I, between the pump beam combiner I and the fiber grating I, between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com